Automatic tea leaf sun-drying system

A tea and rolling device technology, which is applied to climate change adaptation, pre-extraction tea processing, stacking of objects, etc., can solve problems such as large time and energy, occupation of tea makers, and restricting the improvement of the technical level of production lines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

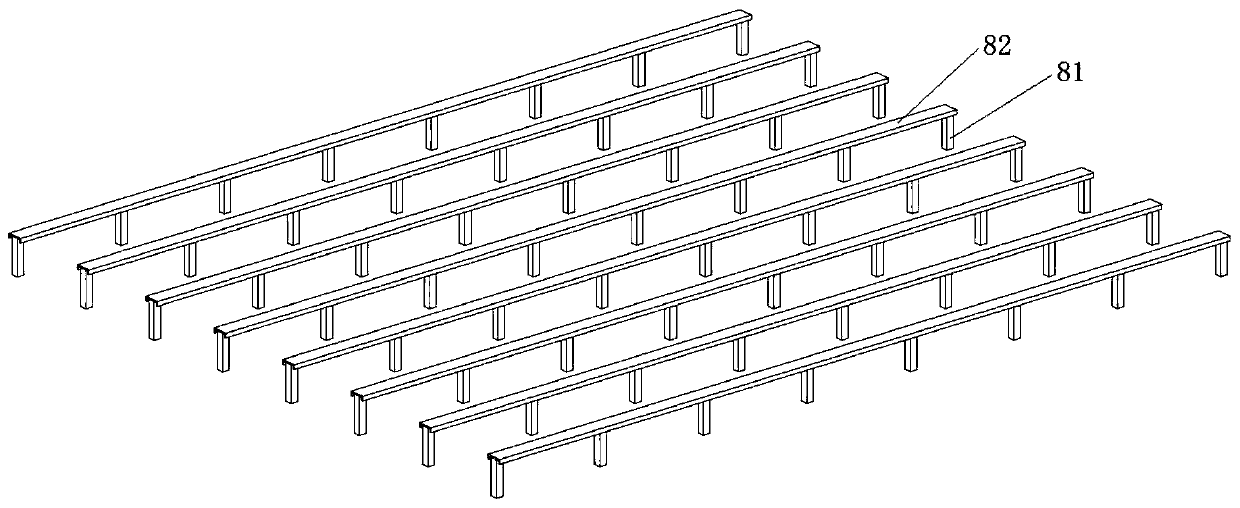

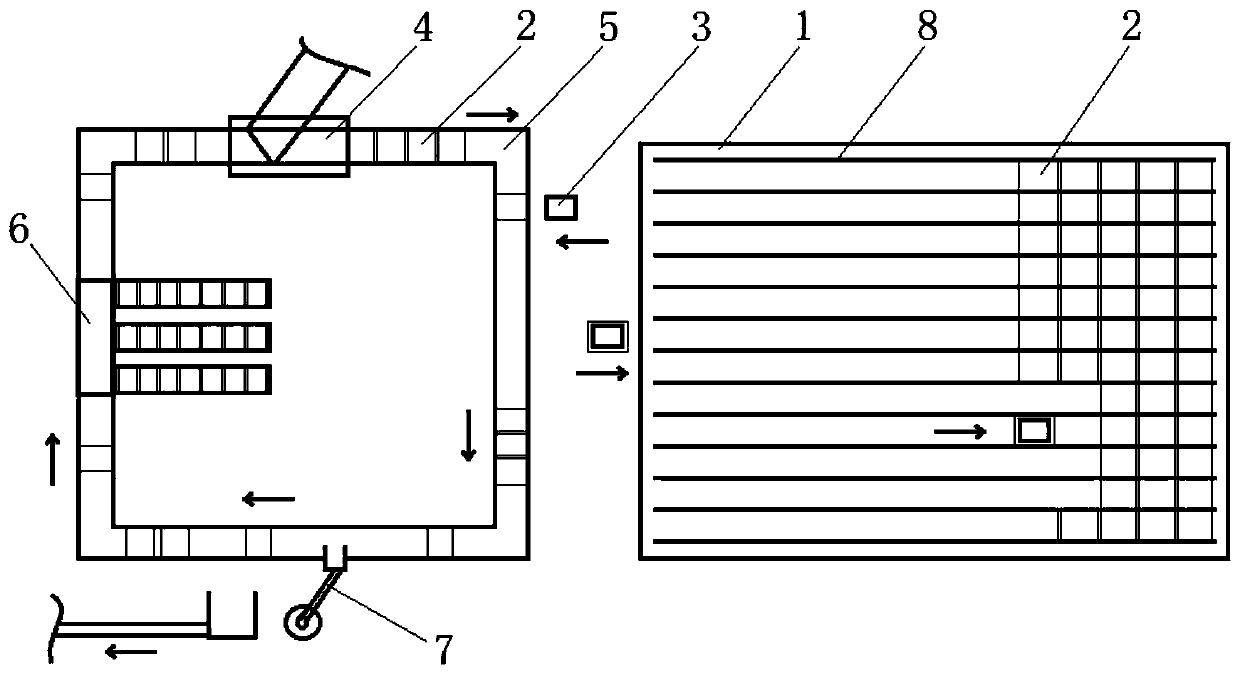

[0040] An automatic tea drying system, wherein a drying field 1 for tea drying is 30m long and 25m wide, and a rain shelter is installed on the drying field 1, and the rain shelter is made of anti-ultraviolet material. Such as figure 1 As shown, the drying field 1 is equipped with a drying support 8 that covers the whole drying field 1; This can avoid the pollution of all kinds of miscellaneous smells "ground gas" on the ground, and can also save the place for drying.

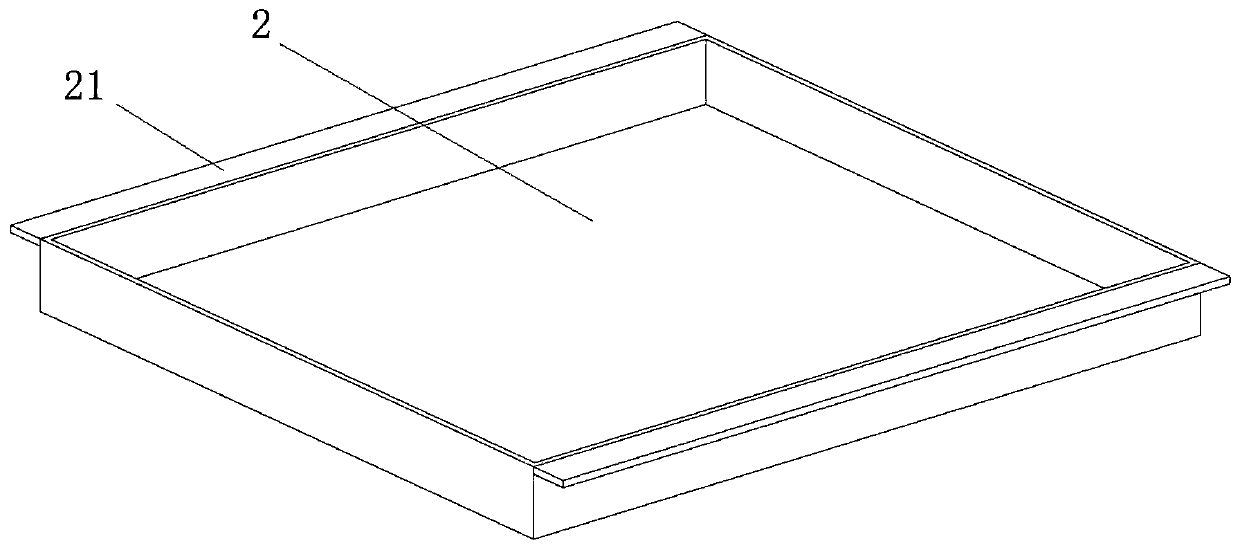

[0041] Such as figure 2 Shown is a tray 2 for holding tea leaves. The tray 2 is in the form of a flat-bottomed tray 2 and is made of food-grade plastic or rust-proof metal. The overall dimensions are L×W×H, mm: 1200×1000×100. Net weight ≤ 30kg, capable of carrying ≥ 50kg of tea. When the tray 2 is covered with tea leaves, the height of the tray 2 is 100mm, and the unit weight is ≤100kg. Clamping ears 21 with a width of 100mm are provided on both sides of the long side of the tray 2.

[0042] Such as ima...

Embodiment 2

[0048] An automatic tea drying system is a further improvement to Embodiment 1, and is different from Embodiment 1: as Figure 6 As shown, the drying field 1 is 35m long and 35m wide, and the conveyor belt of the conveying device 5 is adjacent to three sides of the drying field 1 to wrap it in the middle. Passage 11 is wide 2500mm, and carrying passage 11 is a cross-shaped passage, and drying support 8 is divided into four parts, and the direction of the horizontal support 82 on the drying support 8 of each part is as follows: Figure 5 As shown, the AVG transport trolleys 31 can run side by side in the transport channel 11 . There are four AGV transport trolleys 31 used at the same time.

[0049] When in use, the AGV handling trolley 31 first arranges the tray 2 with tea leaves on one of the four block-shaped drying supports 8, and then arranges the tray 2 with tea leaves on the other several block-shaped drying supports 8 in order. After the tea leaves are dried, this sequ...

Embodiment 3

[0051] An automated tea drying system, such as Figure 7 As shown, it is a further improvement to Embodiment 1, and the difference from Embodiment 1 is: the drying frame 8 is replaced with a drying platform 32 arranged on the drying field 1; wherein the drying platform 32 includes a column arranged on the drying field 1 , drying field 1 is long 80m wide 30m, and column is high 1000mm, and the horizontal bar that is parallel with drying field 1 access direction is installed on the column, and roller is installed on the horizontal bar. The conveying device 5 is docked with the inlet end 321 of the drying platform 32 , and is provided with a pushing device 323 for pushing the tray 2 into the drying platform 32 . The inlet end 321 of the drying platform 32 is higher than the outlet end 322, so that the angle between the drying platform and the horizontal plane is 6 degrees. To a certain position at the inlet end 321 of the drying platform 32, the infrared sensor installed at the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com