A kind of ablation-resistant tungsten-copper alloy and its application

A tungsten-copper alloy, ablation-resistant technology, applied in the direction of spark gap parts, electrical components, spark gaps, etc., can solve the problems that affect the safe and long-term operation of the line, cannot meet the needs of industrialization, and have poor ablation resistance, etc., to achieve good durability Ablative properties, easy operation, and the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

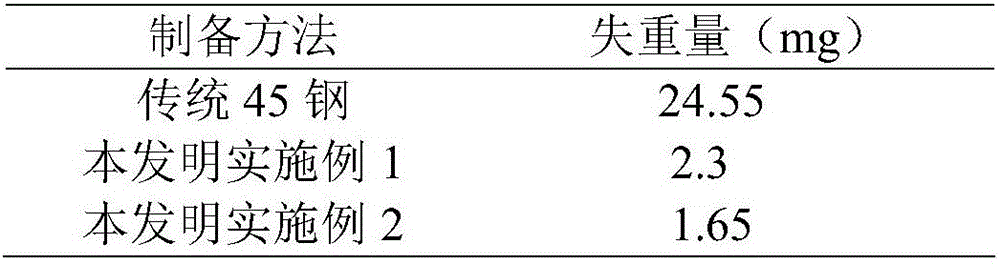

Examples

Embodiment 1

[0029] Preparation of W80Cu18.7Ni0.3TiB with a diameter of 30 mm and a mass percentage of 80:18.7:0.3:1 2 1 an ablation-resistant tungsten-copper alloy ball, comprising the following steps:

[0030] (1) Calculate the masses of tungsten, copper, nickel and titanium diboride according to the mass of the prepared ablation-resistant tungsten-copper alloy ball and the mass percentage of the components to be 261.44g, 61.11g, 0.98g, and 3.27g, respectively.

[0031] (2) Weigh 261.44g of tungsten powder with a particle size of 4-7μm, 3.06g of copper powder with a particle size of 65-74μm as pre-added copper powder (weighed by 5% of the copper mass), and 63.86g of copper powder as pressed powder. Billet copper powder (weighed by 1.1 times the mass of the remaining copper), 0.98g of nickel powder with a particle size of 1-3μm, 3.27g of titanium diboride powder with a particle size of 3-6μm, and a molding agent zinc stearate 3.27 g.

[0032] (3) Put the tungsten powder, pre-added coppe...

Embodiment 2

[0038] Preparation of W80Cu17.7Ni0.3TiB with a diameter of 30 mm and a mass percentage of 80:17.7:0.3:2 2 2 Ablation-resistant tungsten-copper alloy balls, comprising the following steps:

[0039] (1) Calculate the masses of tungsten, copper, nickel and titanium diboride according to the mass of the prepared ablation-resistant tungsten-copper alloy ball and the mass percentage of the components to be 257.11g, 56.89g, 0.96g, and 6.43g, respectively.

[0040] (2) Weigh 257.11g of tungsten powder with a particle size of 4-7μm, 2.84g of copper powder with a particle size of 65-74μm as pre-added copper powder (weighed by 5% of the copper mass), and 59.5g of copper powder as pressed powder. Billet copper powder (weighed by 1.1 times the mass of the remaining copper), 0.96g of nickel powder with a particle size of 1-3μm, 6.43g of titanium diboride powder with a particle size of 3-6μm, and weigh the forming agent zinc stearate 3.21 g.

[0041] (3) Put the tungsten powder, pre-added ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com