Electrolytic tank for copper electrorefining

A copper electrolytic refining and electrolytic cell technology, which is applied in the electrolytic process, electrolytic components, electrodes, etc., can solve problems such as environmental pollution and high energy consumption, and achieve the effects of less investment, energy saving, and lower processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

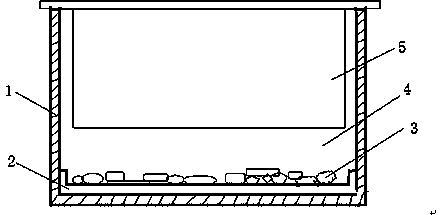

[0017] see figure 1 , the electrolytic cell body 1 of the electrolytically refined graphite anode electrolyzer is made of glass fiber reinforced plastics, the graphite disc 2 is located at the inner bottom of the electrolytic cell body 1, and the graphite disc 2 is connected to the positive pole of the electrolytic power supply.

[0018] When electrolytic refining is used to treat scrap copper, the scrap copper is first processed into small-sized block, flake or powder coarse material 3; A thin sheet is made as the electrolytic cathode 5, and the mixed solution of sulfuric acid and copper sulfate is used as the electrolyte 4 for electrolytic refining.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com