Method for measuring content of silicon in ferromanganese

A determination method and technology of silicon content, applied in the preparation of test samples, color/spectral characteristic measurement, etc., can solve the problems of long analysis period, loss, low content of ferromanganese and silicon, and achieve low analysis cost and high accuracy , good precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

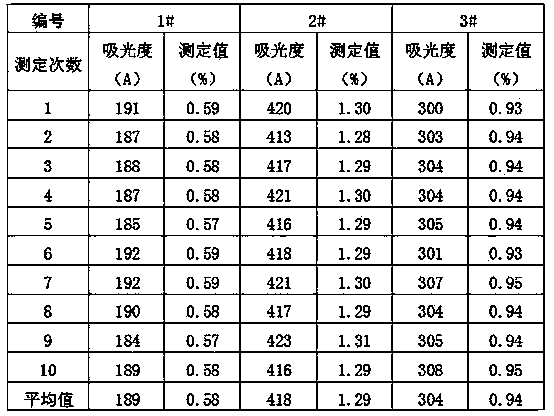

Examples

Embodiment

[0015] Embodiment: the assay method of silicon content in this ferromanganese adopts nitric acid, after the hydrofluoric acid water bath heats and dissolves the sample, adds carbonamide to decompose and destroy the interference of nitrogen oxide compounds, complexes unnecessary fluorine ion with saturated boric acid, in c( h + )=0.1~0.6mol / L acidity, make silicic acid and molybdic acid form yellow silicon-molybdenum heteropolyacid; Finally measure its absorbance; its specific assay process is as follows.

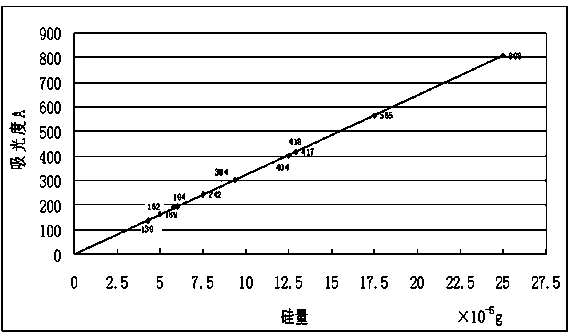

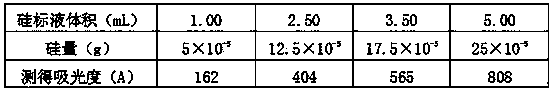

[0016] 1. Draw a standard curve:

[0017] 1. Preparation of iron standard solution:

[0018] Weigh 1.0000g metallic iron (99.9wt%) in a 100mL conical flask, add 20mL nitric acid (1+1) to dissolve, boil to remove nitrogen oxides, cool to room temperature, transfer the solution into a 1000mL volumetric flask, dilute with water to the mark, mix Mix well and transfer to a plastic bottle for later use; 1.00mL of this solution contains 1000.0μg iron. The above-mentioned nitric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com