Preparation method of hollow bowl-shaped carbon-based metal oxide composite material

A technology of composite materials and hollow bowls, which is applied in the field of preparation of energy storage materials, can solve the problems of no contribution to the electrochemical performance of materials and reduce the volumetric energy density of batteries, and achieve increased volumetric energy density, increased packing density, and high volume The effect of energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

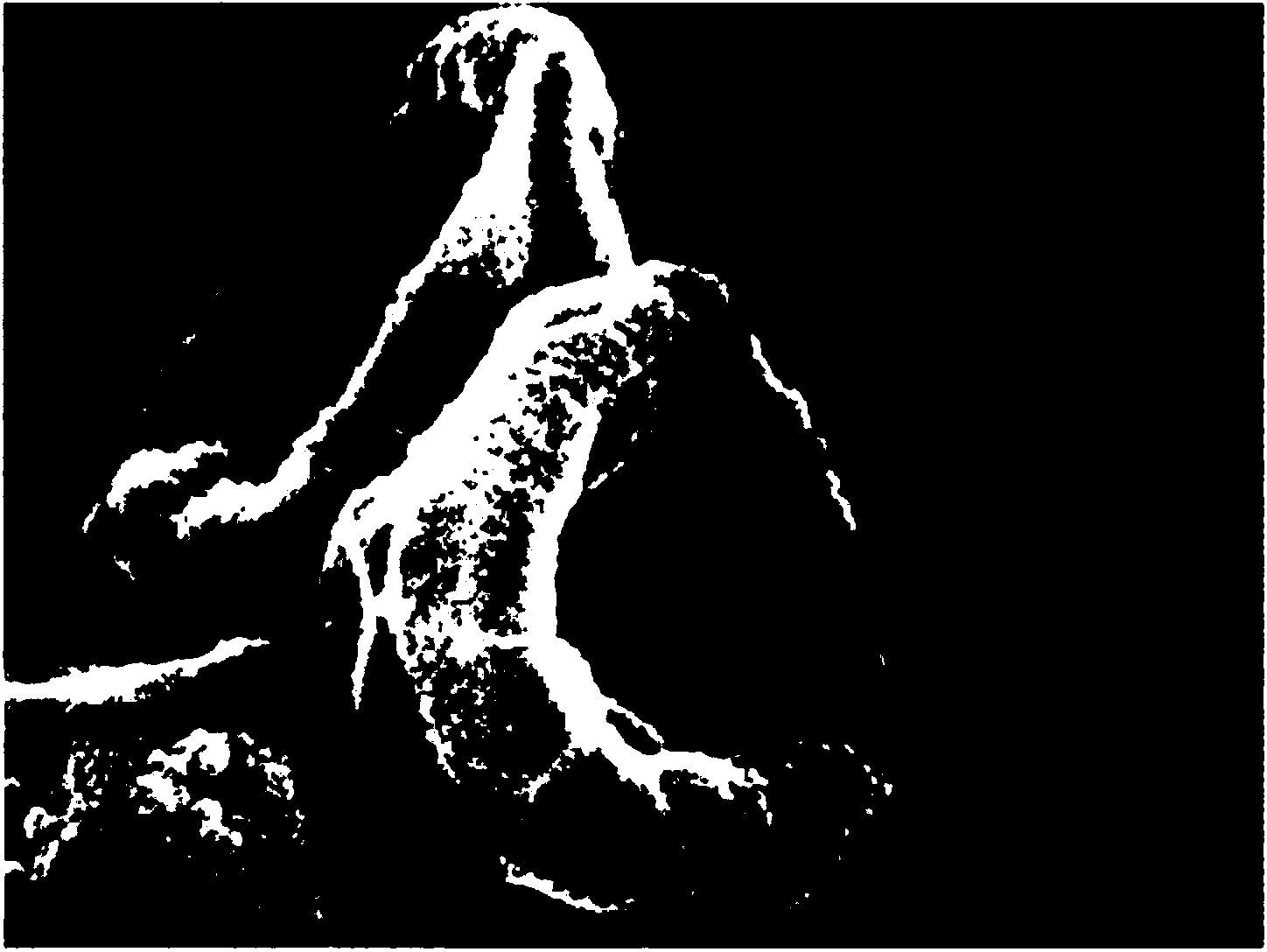

[0016] This embodiment includes the following steps:

[0017] The first step: Weigh 0.1g of hollow bowl-shaped polystyrene microspheres into a flask, add 40mL of concentrated sulfuric acid with a mass concentration of 98%, ultrasonically disperse for 15 minutes, and then stir and react at 40°C for 4 hours to obtain the sulfuric acid The polystyrene microspheres were washed with ethanol until neutral, and dried for later use; the ultrasonic power was 250W; the stirring speed was 400r / m.

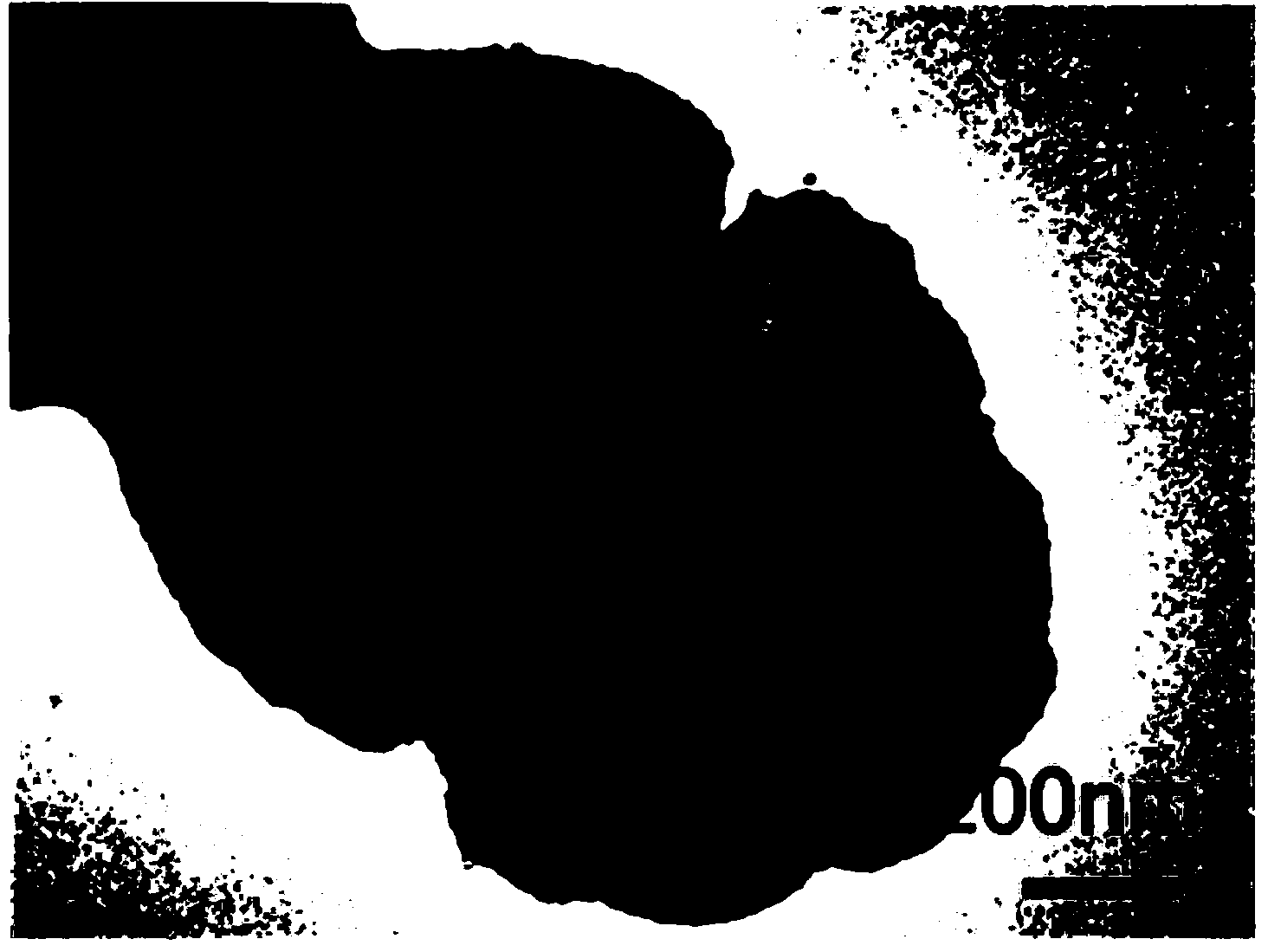

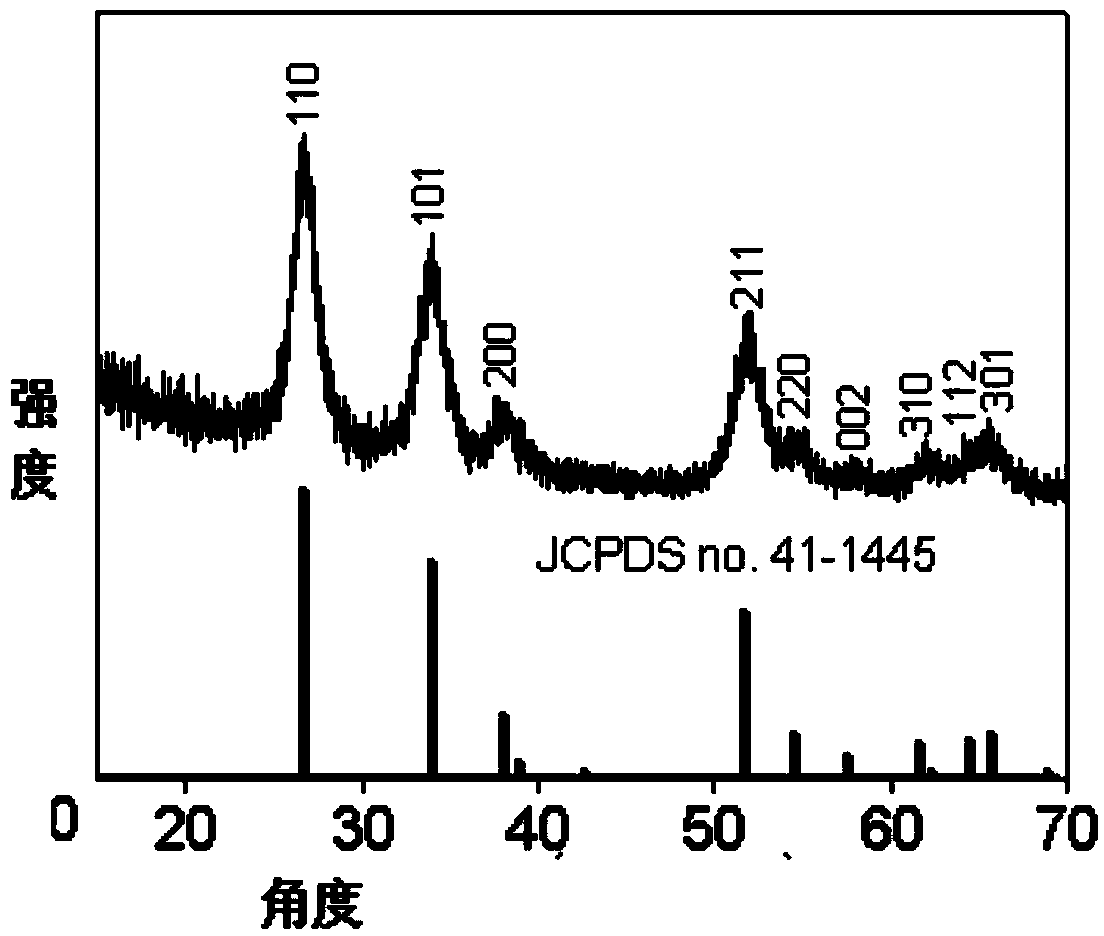

[0018] Step 2: Take 10 mg of hollow bowl-shaped sulfonated polystyrene microspheres, add them to 30 mL of 35 mM thioglycolic acid solution, and ultrasonically disperse for 10 minutes. The ultrasonic power is 250 W; then add 30 mg of SnCl in sequence 2 , 30mg of urea and 0.3mL of strong acid, and then stirred and reacted at 40°C for 4 hours at a stirring speed of 400r / m; the obtained product was centrifuged, and then washed with ethanol for 6 times to obtain a hollow bowl-shaped tin dioxide com...

Embodiment 2

[0025] This embodiment includes the following steps:

[0026] The first step: Weigh 0.5g of hollow bowl-shaped polystyrene microspheres into a flask, add 40mL of concentrated sulfuric acid with a mass concentration of 98%, ultrasonically disperse for 15 minutes, and then stir and react at 80°C for 6 hours to obtain the sulfuric acid The polystyrene microspheres were washed with ethanol until neutral, and dried for later use. The ultrasonic power is 250W; the stirring speed is 400r / m.

[0027] Step 2: Weigh 10 mg of the hollow bowl-shaped sulfonated polystyrene microspheres prepared above and add them to 120 mL of deionized water, ultrasonically disperse for 10 minutes, then add 36.2 mg of sodium citrate and 177.5 mg of hexamethylenetetramine in sequence, 177.5 mg of zinc nitrate was stirred and reacted in an oil bath at 90°C for 6 hours, and the obtained product was washed 5 times with ethanol to obtain a hollow bowl-shaped precursor of sulfonated zinc oxide composite materia...

Embodiment 3

[0030] This embodiment includes the following steps:

[0031] The first step: Weigh 1g of hollow bowl-shaped polystyrene balls into a flask, add 50mL of concentrated sulfuric acid with a mass concentration of 98%, ultrasonically disperse for 15 minutes, and then stir and react at 80°C for 6 hours to obtain the sulfonated polystyrene Styrene microspheres were washed with ethanol until neutral and dried for later use. The ultrasonic power is 250W; the stirring speed is 400r / m.

[0032] Step 2: Weigh 50 mg of hollow bowl-shaped sulfonated polystyrene microspheres, add them to 400 mL of deionized water, disperse ultrasonically for 10 minutes, then add 72.5 mg of sodium citrate, 355 mg of hexamethylenetriamine, and 750 mg of nickel sulfate , stirred and reacted in an oil bath at 90°C for 6 hours, and the obtained product was washed with ethanol for 5 times to obtain a hollow bowl-shaped precursor of nickel oxide composite material.

[0033] The third step: calcinate the product i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com