Preparation method of polyacrylamide emulsion

A technology of polyacrylamide and acrylamide series, which is applied in the field of preparation of polyacrylamide emulsion, and can solve problems such as disturbance of emulsion stability system, increase of emulsion production cost, and increase of emulsion viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

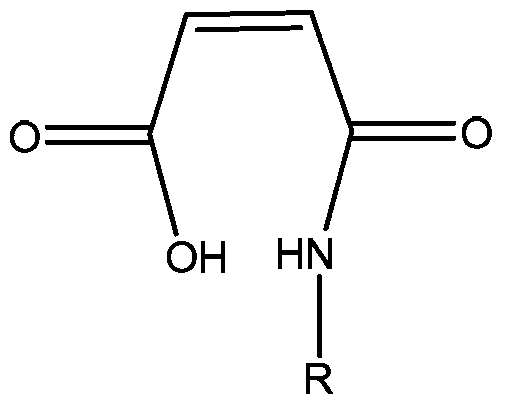

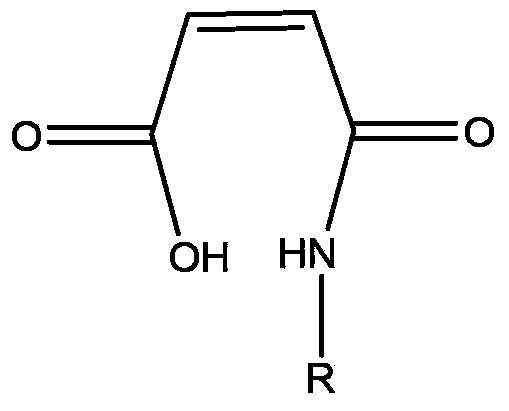

Image

Examples

preparation example Construction

[0015] The invention provides a method for preparing polyacrylamide emulsion, wherein the method includes: (1) initiating acrylamide monomers, anionic monomers containing double bonds, polymerizable emulsifiers, chelating agents, and azo Mixing agent, oxidizing agent and water to form an aqueous solution, and adjusting the pH value of the aqueous solution to 7-9; (2) forming an oil solution with an emulsifier and an organic solvent; (3) mixing the aqueous solution with the oil solution to form an oil-in-oil solution water emulsion; (4) After deoxygenating the water-in-oil emulsion, adding a reducing agent, so that the water-in-oil emulsion undergoes polymerization reaction at a first temperature and a second temperature in sequence, and the second temperature is higher than the first temperature a temperature.

[0016] In the present invention, the polymerizable emulsifier in step (1) refers to that compared with conventional emulsifiers, in addition to having hydrophilic and ...

Embodiment 1

[0053] At 20°C, 100g of deionized water, 100g of acrylamide, 20g of acrylic acid, and 5g of monododecylamine maleate (according to the preparation method in the literature: Daily Chemical Industry, 2006, 36 (6): 345-347 ) into a 1000mL beaker, stirred evenly, and then slowly added 50% by weight of sodium hydroxide aqueous solution to adjust the pH value of the aqueous solution to 7. Then add 0.02 g of disodium edetate, 0.01 g of ammonium persulfate, and 0.05 g of azobisisobutylsulfinium hydrochloride into the beaker.

[0054] Mix 3.79g Span-80 with 4.21g Tween-80, the hydrophilic-lipophilic balance value of the obtained mixed emulsifier is 9.93, and then mix the mixed emulsifier with 90g white oil (boiling point is 200-250°C, flash point 80 ℃) completely dissolved to make an oil solution.

[0055] Add the above aqueous solution into the oil solution, and emulsify for 1 min with a high-speed shear dispersing emulsifier to obtain a stable milky white inverse emulsion. After de...

Embodiment 2

[0061] At 25°C, 150g of deionized water, 100g of acrylamide, 50g of acrylic acid, and 7.5g of monohexadecylamine maleate (according to the literature: Daily Chemical Industry, 2006, 36 (6): 345-347 prepared maleic acid Acid monododecylamine method, using maleic acid and hexadecylamine) was added into a 1000mL beaker, stirred evenly, then slowly added 50% by weight sodium hydroxide aqueous solution and adjusted the pH value of the aqueous solution to 8. Then add 0.2 g of disodium edetate, 0.2 g of ammonium persulfate, and 0.5 g of azobisisobutylsulfinium hydrochloride into the beaker.

[0062] Mix 7.2g Span-80 with 4.8g Tween-80, the hydrophilic-lipophilic balance value of the obtained mixed emulsifier is 8.58, and then mix the mixed emulsifier with 150g white oil (boiling point: distillation range 240-280°C, flash point 100 ℃) completely dissolved to make an oil solution.

[0063] Add the above aqueous solution into the oil solution, and emulsify for 1 min with a high-speed s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

| Flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com