Method for sterilization of campylobacter on whole-chicken slaughtering processing production line

A processing method and production line technology, applied in the direction of preserving meat/fish with acid, etc., can solve the problems of accelerated degradation and poor stability of inosinic acid, and achieve the effect of ensuring the freshness of the meat and the reasonable temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] single factor test

[0021] Firstly, conduct a preliminary screening of the organic acids allowed to be added in the "GB 2760-2011 Food Safety National Standard Food Additive Use Standard" issued by the Ministry of Health. Campylobacter jejuni in the same culture state were treated with different concentrations of organic acids in a 20°C water bath for 10 minutes. After the acid solution was discarded, the plates were counted, and the inhibitory rate of each organic acid on Campylobacter jejuni 11168 strain was calculated. The results showed that among acetic acid, citric acid and lactic acid, lactic acid had the best inhibitory effect on Campylobacter jejuni 11168 strain.

[0022] Using the control variable method, according to the inhibitory rate of lactic acid on Campylobacter jejuni 11168 strain, the three single factors (concentration, time, temperature) that affect the bacteriostatic effect of lactic acid were tested separately, and the best antibacterial interv...

Embodiment 2

[0024] Combination test

[0025] 1. factorial design

[0026] Define the highest and lowest values for the three single factors and determine the three-level coding.

[0027] Table 1 Response surface analysis factors and levels

[0028]

[0029] 2. Test design

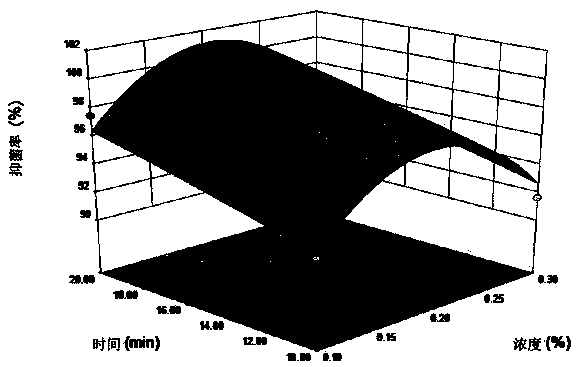

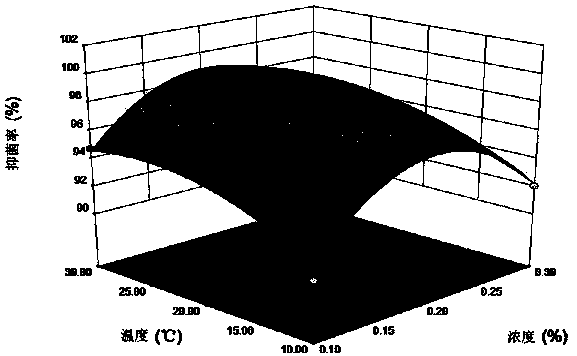

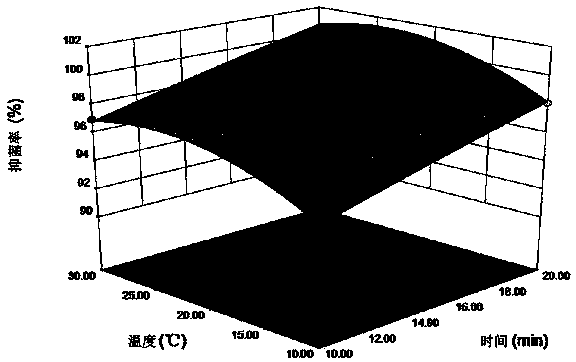

[0030] Using Box-Behnken Design (BBD) to design the experimental program, and based on this, 17 groups of experiments were carried out with the bacteriostatic rate and inosinic acid content as the response value, of which 5 groups were repeated experiments at the center point.

[0031] Table 2 Response surface analysis scheme and test results

[0032]

[0033] The operation of using the plate counting method to obtain the bacteriostatic rate is as follows: treat Campylobacter in the same culture state according to the three factors in Table 2, and immediately dilute the acid concentration in the bacterial suspension to less than 0.01% with PBS to terminate the reaction when the treatment time is up. ...

Embodiment 4

[0048] Validate predictions

[0049] In order to make the antibacterial rate and inosinic acid content as high as possible, according to the experimental results and the quadratic polynomial regression equation, the best experimental combination of various factors was obtained by using Design Expert 8.0 software: lactic acid concentration 0.19%, treatment time 17min, The processing temperature is 20.9°C. And the predicted values of two response values were obtained: the bacteriostatic rate was 98.619%, and the content of inosinic acid was 1.86781mg / g.

[0050] In order to judge the feasibility of the scheme, experiments were carried out on the whole chicken samples from the slaughterhouse to verify the accuracy of the predicted value. After the internal organs of the whole chicken are taken out, 20 chickens are randomly selected, marked, soaked in clean water with a lactic acid concentration of 0.19% at 20.9°C for 17 minutes, and then hung on the production line for spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com