High-performance composite nanofiltration membrane with resistance to oxidation of organic solvent and chlorine, as well as preparation method and application of membrane

A composite nanofiltration membrane, organic solvent-resistant technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc. Low membrane flux and other problems, to achieve the effect of improving flux and selective rejection performance, easy operation and control, and high flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

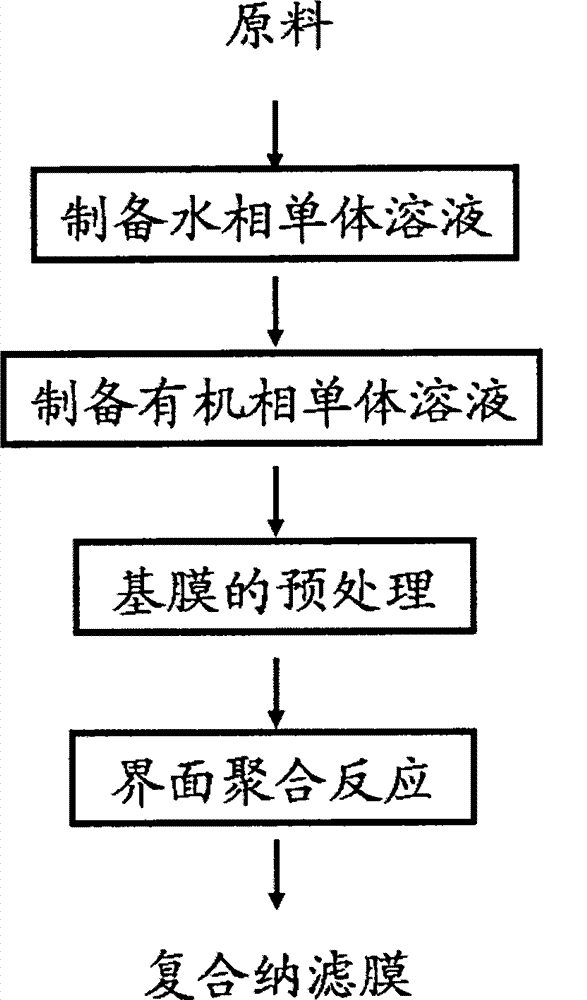

Method used

Image

Examples

Embodiment 1

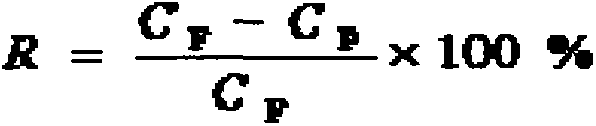

[0064] The used high molecular polymer amine, polybasic acid chloride, acid acceptor and surfactant are the same as those of the comparative example. Sodium chloride was added as a supporting electrolyte when preparing the aqueous phase monomer solution. The concentration of the supporting electrolyte in the aqueous monomer solution is 0.5 mol / L, the mass percent concentration of the surfactant is 0.002%, other parameters and processes are the same as those of the comparative example, and the test conditions are the same as those of the comparative example. The nanofiltration membrane prepared in this example is to Na 2 SO 4 The rejection rate is 96%, and the solution flux is 53L / (m 2 h); the rejection rate to NaCl is 71%, and the solution flux is 55L / (m 2 h).

Embodiment 2

[0066] The high molecular polymer amine and polyacyl chloride used are the same as those of the comparative example. No acid acceptors and surfactants are added. Sodium chloride was added as a supporting electrolyte when preparing the aqueous phase monomer solution. The concentration of the supporting electrolyte in the aqueous phase monomer is 0.5mol / L, the immersion time of the modified base film in the aqueous phase monomer solution is 30min, other parameters and processes are the same as those of the comparative example, and the test conditions are the same as those of the comparative example. The nanofiltration membrane prepared in this example is to Na 2 SO 4 The rejection rate is 90%, and the solution flux is 62L / (m 2 h); the rejection rate to NaCl is 57%, and the solution flux is 63L / (m 2 h).

Embodiment 3

[0068] The high molecular polymer amine and polyacyl chloride used are the same as those of the comparative example. No acid acceptors and surfactants are added. Sodium chloride was added as a supporting electrolyte when preparing the aqueous phase monomer solution. The mass percentage concentration of polymer amine in the aqueous phase monomer is 0.8%, the concentration of supporting electrolyte is 0.5mol / L, other parameters and processes are the same as those of the comparative example, and the test conditions are the same as those of the comparative example. The nanofiltration membrane prepared in this example is to Na 2 SO 4 The rejection rate is 96%, and the solution flux is 52L / (m 2 h); the rejection rate to NaCl is 53%, and the solution flux is 59L / (m 2 h).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com