Preparation method of magnetic stripping type montmorillonite nanocomposite material for wastewater treatment

A nano-composite material and montmorillonite technology, which is applied in the field of preparation of magnetic exfoliated montmorillonite nano-composite materials, can solve the problems of difficult recovery of adsorbent materials, low adsorption efficiency, etc., and achieves simple preparation process, strong adsorption capacity, high The effect of adsorption properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

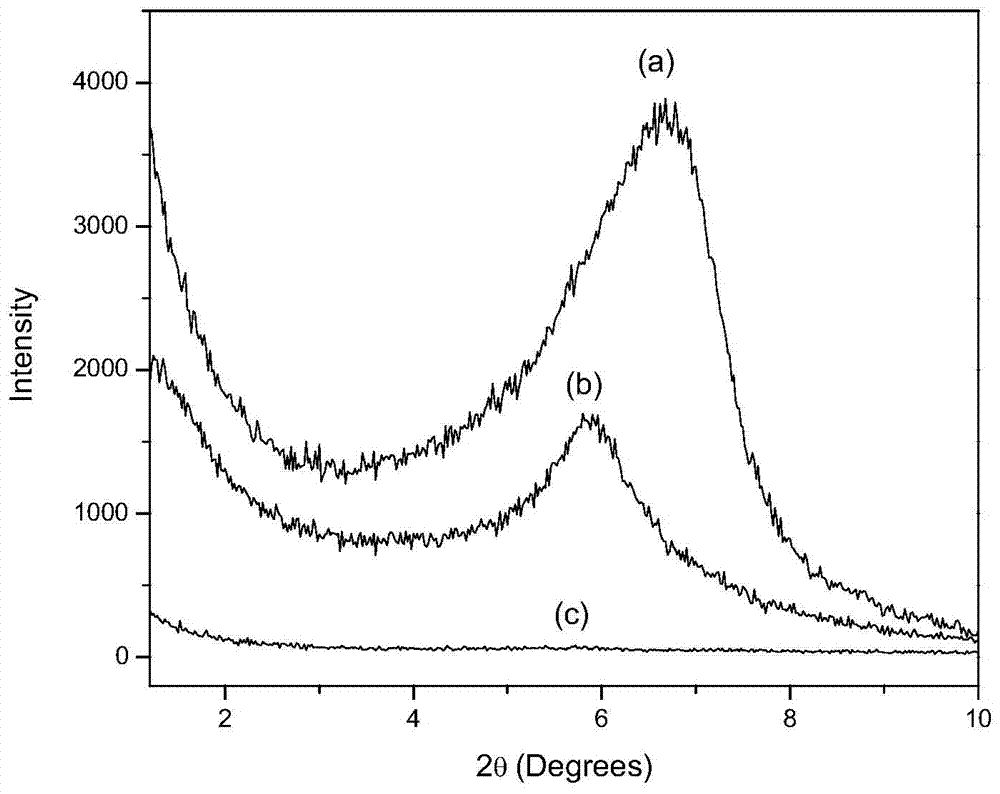

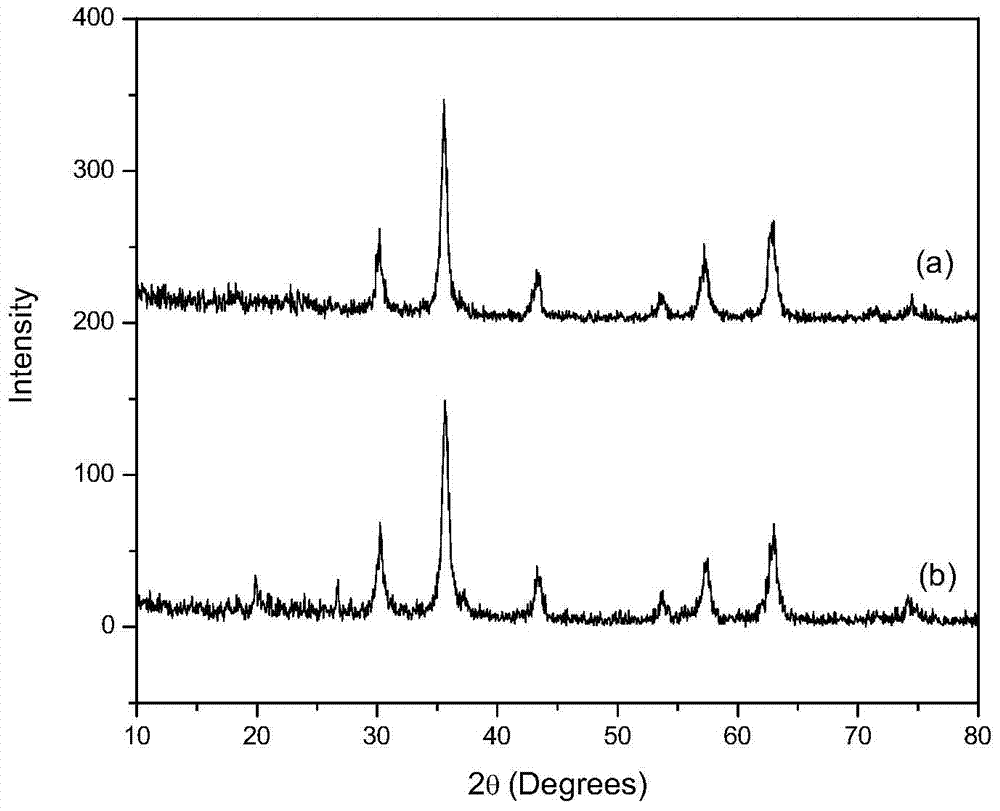

[0021] Disperse 3.0 g of sodium montmorillonite in 600 mL of distilled water, adjust the pH of the solution to 3 with hydrochloric acid, then add 2.4 g of modifier to the above solution, mix and stir for 4 hours, filter and wash with water to obtain organic modified montmorillonite. off the soil. Take 1.66g of organically modified montmorillonite and disperse it in 700mL of distilled water, add 2.69g of ferric chloride hexahydrate and 1.32g of ferrous chloride tetrahydrate, pass N 2 After stirring for 30 minutes, add ammonia solution at 80°C, control the pH value of the solution at 10-11, stir and react for 2 hours, cool, filter, wash, dry, grind and disperse to obtain magnetic exfoliation montmorillonite nanocomposites.

[0022] Take 0.10g of the above-mentioned nanocomposite material and put it into 100mL methylene blue solution with an initial concentration of 60mg / L. After adsorption for 6h, after the adsorbent is separated by a magnet, the concentration of methylene blue ...

Embodiment 2

[0026] Disperse 3.0 g of sodium montmorillonite in 300 mL of distilled water, adjust the pH of the solution to 3 with hydrochloric acid, then add 1.2 g of modifier to the above solution, mix and stir for 4 hours, filter and wash with water to obtain organic modified montmorillonite. off the soil. Take 2.32g of organically modified montmorillonite and disperse it in 700mL of distilled water, add 2.69g of ferric chloride hexahydrate and 1.32g of ferrous chloride tetrahydrate, pass N 2 After stirring for 30 minutes, add ammonia solution at 80°C, control the pH value of the solution at 10-11, stir and react for 2 hours, cool, filter, wash, dry, grind and disperse to obtain magnetic exfoliation montmorillonite nanocomposites.

[0027] Take 0.10g of the above-mentioned nanocomposite material and put it into 100mL methylene blue solution with an initial concentration of 60mg / L. After adsorption for 6h, after the adsorbent is separated by a magnet, the concentration of methylene blue ...

Embodiment 3

[0031] Disperse 4.5g of sodium-based montmorillonite in 300mL of distilled water, adjust the pH of the solution to 3 with hydrochloric acid, then add 0.9g of modifier to the above solution, mix and stir for 4 hours, filter and wash with water to obtain organic modified montmorillonite. off the soil. Take 2.69g of organically modified montmorillonite and disperse it in 700mL of distilled water, add 2.69g of ferric chloride hexahydrate and 1.32g of ferrous chloride tetrahydrate, pass N 2 After stirring for 30 minutes, add ammonia solution at 80°C, control the pH value of the solution at 10-11, stir and react for 2 hours, cool, filter, wash, dry, grind and disperse to obtain magnetic exfoliation montmorillonite nanocomposites.

[0032] Take 0.10g of the above-mentioned nanocomposite material and put it into 100mL methylene blue solution with an initial concentration of 60mg / L. After adsorption for 6h, after the adsorbent is separated by a magnet, the concentration of methylene bl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com