Preparation method of cadmium selenide nano powder

A technology of nano-powder and cadmium selenide, which is applied in the field of preparation of cadmium selenide nano-powder, can solve the problems of using toxic organics, complicated operation process, long preparation period and the like, and achieves low temperature, low preparation temperature, excellent The effect of optoelectronic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) Weigh 0.002 mol of selenium, add it to 3 ml of concentrated nitric acid, heat and stir continuously until it is completely dissolved; then add 50 ml of deionized water.

[0022] (2) Weigh 0.0016 mol of cadmium nitrate and 0.0017 mol of citric acid respectively, and dissolve them in the solution obtained in step (1).

[0023] (3) Place the solution obtained in step (2) on an electric heating mantle at a temperature of 300°C for heating and stirring; as the water evaporates, a colloidal precursor is obtained; further heating the precursor burns and releases a large amount of smoke, and waits for the reaction to stop. The cadmium selenide nanopowder is obtained.

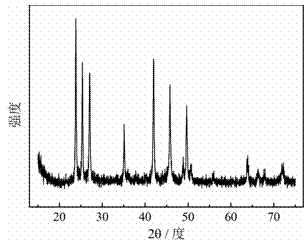

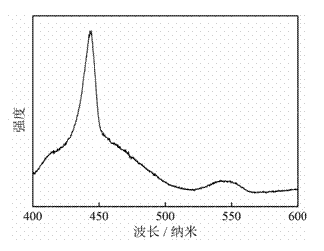

[0024] The X-ray diffraction pattern of prepared cadmium selenide nanopowder is as follows figure 1 As shown, it can be seen that the powder is hexagonal cadmium selenide, and the crystallization is good; the emission spectrum of the prepared cadmium selenide nanopowder under the excitation of 325 nm wavelen...

Embodiment 2

[0026] (1) Weigh 0.002 mol of selenium, add it to 3 ml of concentrated nitric acid, heat and stir continuously until it is completely dissolved; then add 40 ml of deionized water.

[0027] (2) Weigh 0.0014 mol of cadmium nitrate and 0.0012 mol of citric acid respectively, and dissolve them in the solution obtained in step (1).

[0028] (3) Place the solution obtained in step (2) on an electric heating mantle with a temperature of 250°C for heating and stirring; as the water evaporates, a colloidal precursor is obtained; further heating the precursor burns and releases a large amount of smoke, and waits for the reaction to stop. The cadmium selenide nanopowder is obtained.

Embodiment 3

[0030] (1) Weigh 0.002 mol of selenium, add it to 3 ml of concentrated nitric acid, heat and stir continuously until it is completely dissolved; then add 60 ml of deionized water.

[0031] (2) Weigh 0.0018 mol of cadmium nitrate and 0.003 mol of citric acid respectively, and dissolve them in the solution obtained in step (1).

[0032] (3) Place the solution obtained in step (2) on a heating mantle with a temperature of 400°C for heating and stirring; with the evaporation of water, a colloidal precursor is obtained; further heating the precursor burns and releases a large amount of smoke, and waits for the reaction to stop. The cadmium selenide nanopowder is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com