Water retention and slow release type biological compound fertilizer and preparation method thereof

A biological compound fertilizer, slow-release technology, applied in the agricultural field, to solve the effects of poor stability, good biological efficacy, and low persistence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

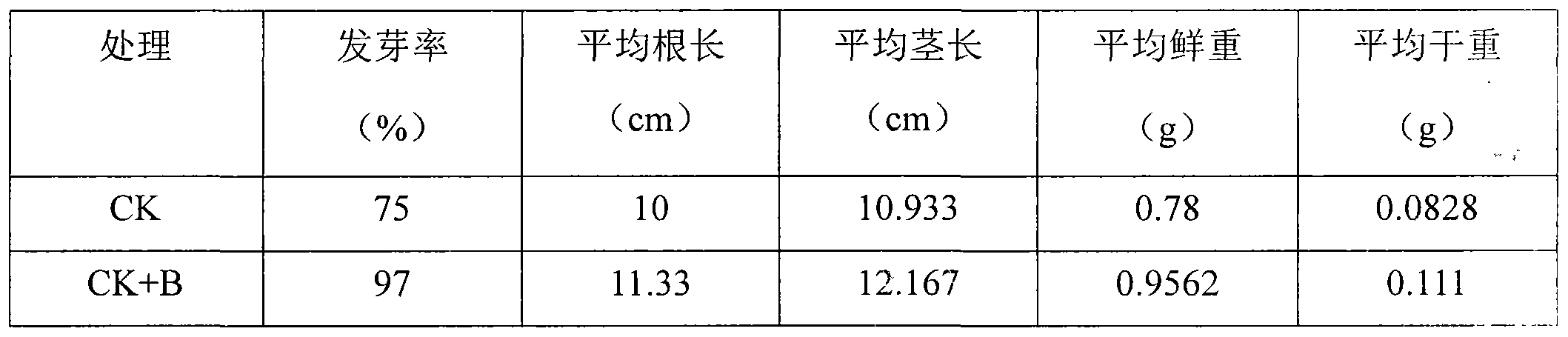

Examples

Embodiment 1

[0023] (1) Dilute 25% acrylic acid with distilled water, stir under an ice-water bath, neutralize with sodium hydroxide solution, the neutralization degree is 70%, add 15% acrylamide, 0.02% crosslinking agent, 0.02% initiator, 15% inorganic mineral raw materials and 35% urea, disperse and mix at 300 rpm for 30 minutes to obtain an aqueous phase system;

[0024] (2) Mix 1% dispersant with cyclohexane, disperse and mix evenly at 300 rpm under heating conditions, until the dispersant is completely dissolved, and obtain an oil phase system containing cyclohexane and dispersant;

[0025] (3) Under the condition of nitrogen protection, mix the water phase system and the oil phase system at a ratio of 1:3 (V / V), control the temperature at 70 ° C, disperse at a high speed at 500 rpm, react for 3 hours, cool to room temperature, filter, and recover the solution Reuse and dry the solid matter to obtain a series of granular fertilizer granules;

[0026] (4) Add the concentrated bacteria...

Embodiment 2

[0029] (1) Dilute 40% acrylic acid with distilled water, stir under ice water bath, neutralize with sodium hydroxide solution, the neutralization degree is 50%, add 30% acrylamide, 1% crosslinking agent, 1% initiator, 5% inorganic mineral raw materials and 20% urea, disperse and mix at 300 rpm for 30 minutes to obtain an aqueous phase system;

[0030] (2) Mix 2% dispersant with cyclohexane, disperse and mix at 300 rpm under heating conditions, until the dispersant is completely dissolved, and obtain an oil phase system containing cyclohexane and dispersant;

[0031] (3) Under the condition of nitrogen protection, mix the water phase system and the oil phase system at a ratio of 1:4 (V / V), control the temperature at 80°C, disperse at a high speed at 500 rpm, and react for 4 hours, cool to room temperature, filter, and recover the solution Reuse and dry the solid matter to obtain a series of granular fertilizer granules;

[0032] (4) Add the concentrated bacterial suspension to...

Embodiment 3

[0035] (1) After diluting 30% acrylic acid with distilled water, stir under an ice-water bath, neutralize with sodium hydroxide solution, the neutralization degree is 60%, add 20% acrylamide, 0.5% crosslinking agent, 0.5% initiator, 10% inorganic mineral raw materials and 30% urea, disperse and mix at 300 rpm for 30 minutes to obtain an aqueous phase system;

[0036] (2) Mix 1.5% dispersant with cyclohexane, disperse and mix at 300 rpm under heating conditions, until the dispersant is completely dissolved, and obtain an oil phase system containing cyclohexane and dispersant;

[0037] (3) Under the condition of nitrogen protection, mix the water phase system and the oil phase system at a ratio of 1:2 (V / V), control the temperature at 60 ° C, disperse at a high speed at 500 rpm, react for 2 hours, cool to room temperature, filter, and recover the solution Reuse and dry the solid matter to obtain a series of granular fertilizer granules;

[0038] (4) Add the concentrated bacteri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com