Method for preparing lobster shell chitosan through cooperation of ultrasonic wave and CDA (Chitin Deacetylase)

The technology of lobster shell and ultrasonic wave is applied in the field of ultrasonic cooperating with CDA enzyme to prepare lobster shell chitosan. Time, shortened deacetylation time, high deacetylation degree effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

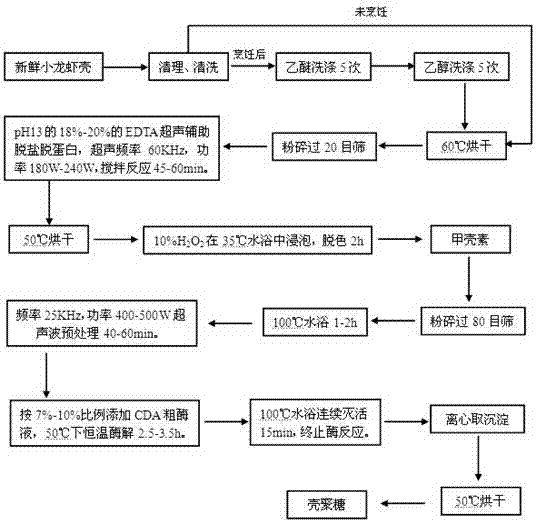

Image

Examples

Embodiment 1

[0022] Example 1: Preparation of chitosan from fresh crayfish head chitosan before cooking: Wash the head and shell of fresh freshwater crayfish, place it in an oven at 60°C to dry, and use a pulverizer to pulverize until it passes through a 20-mesh sieve. Weigh a certain amount of crayfish head shell powder before cooking into a beaker, add a 20% EDTA solution with pH=13 in a material-to-liquid ratio of 1g:30ml, and place it in an ultrasonic cleaning with an ultrasonic frequency of 60KHz and a power of 240W. In the apparatus, the reaction was stirred for 60 min, filtered and the filter residue was washed with distilled water. The above filter residues were collected, dried at 50 °C, and then soaked in a 35 °C water bath with 10% hydrogen peroxide solution, decolorized for 2 hours, and the white powder after washing and drying was chitin. The crayfish head shell chitin was crushed to pass through an 80-mesh sieve, placed in a beaker, added with distilled water in a ratio of ...

Embodiment 2

[0023] Example 2: Preparation of fresh crayfish tail chitosan before cooking: Wash the fresh freshwater crayfish tail shell (the remaining part after removing the head and shell), dry it in a 60°C oven, use a pulverizer to pulverize until it passes a 20-mesh sieve, and weigh it. Take a certain amount of crayfish tail shell powder before cooking in a beaker, add 18% EDTA solution with pH=13 according to the material-to-liquid ratio of 1g:24ml, and place it in an ultrasonic cleaner with an ultrasonic frequency of 60KHz and a power of 180W. , the reaction was stirred for 45 min, filtered and the filter residue was washed with distilled water. The above filter residues were collected, dried at 50 °C, and then soaked in a 35 °C water bath with 10% hydrogen peroxide solution, decolorized for 2 hours, and the white powder after washing and drying was chitin. The crayfish tail shell chitin was pulverized to pass an 80-mesh sieve, placed in a beaker, added with distilled water at a r...

Embodiment 3

[0024] Example 3: Preparation of fresh crayfish chitosan before cooking: Wash fresh freshwater crayfish shells (including head shells and tail shells), dry them in an oven at 60°C, use a pulverizer to pulverize until they pass a 20-mesh sieve, and weigh a certain amount of chitosan. Measure the crayfish shell powder before cooking in a beaker, add 19% EDTA solution with pH=13 according to the material-to-liquid ratio of 1g: 28ml, put it in an ultrasonic cleaner with an ultrasonic frequency of 60KHz and a power of 220W, and stir. React for 55min, filter and wash the filter residue with distilled water. The above filter residues were collected, dried at 50 °C, and then soaked in a 35 °C water bath with 10% hydrogen peroxide solution, decolorized for 2 hours, and the white powder after washing and drying was chitin. The crayfish shell chitin was pulverized to pass through an 80-mesh sieve, placed in a beaker, added with distilled water in a ratio of 1g:20ml of material to liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com