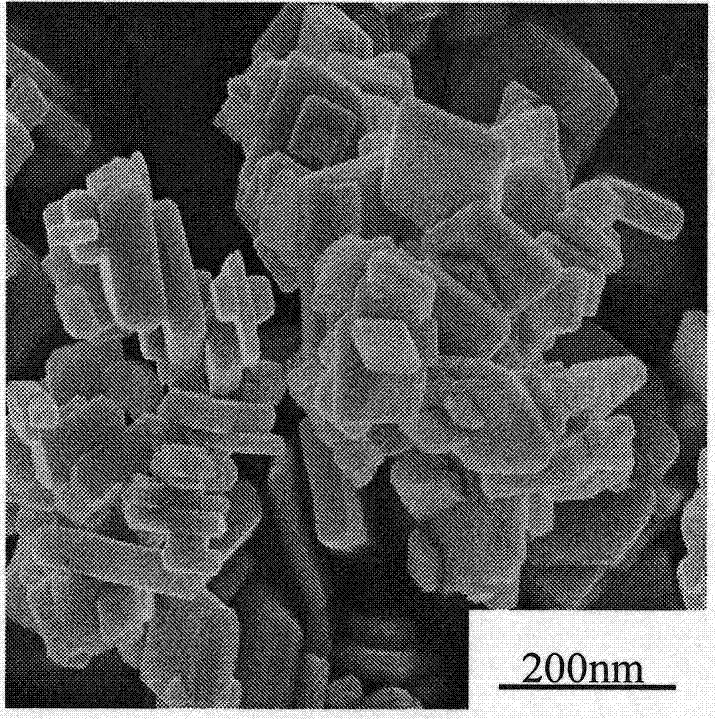

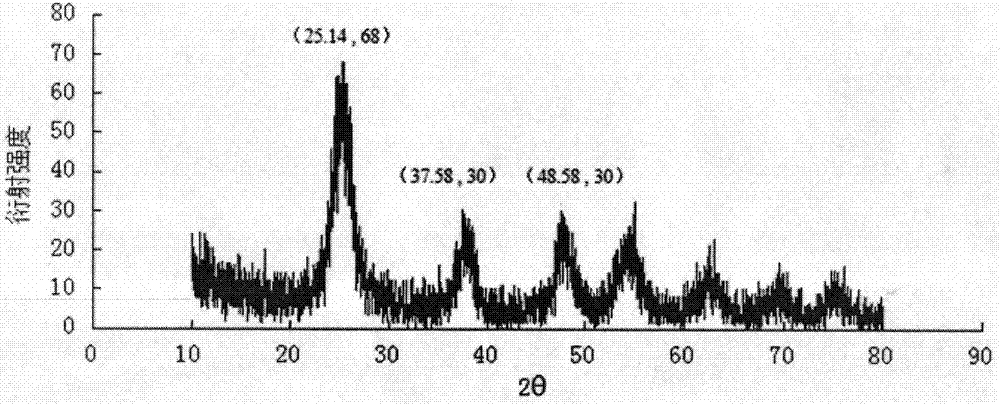

Normal-temperature preparation method of {001} surface anatase TiO2 monocrystals

An anatase and single crystal technology, applied in the field of photocatalytic materials, can solve the problems of complex preparation process and energy consumption, and achieve the effect of promoting complete hydrolysis, simple device and inhibiting polymerization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] ① Measure 30.4mL of absolute ethanol and add it to 35.2mL of butyl titanate, and record it as solution A;

[0028] ② Take 30.4mL of absolute ethanol and add it to 180mL of water, and add 20.2mL of HF at the same time, and record it as solution B;

[0029] ③ Add solution B to solution A drop by drop, control the drop rate at 2-3 drops per second, mix and stir at low speed for 2 hours to obtain TiO 2 Sol, aged at room temperature;

[0030] ④The aged 2d TiO 2 The sol was centrifugally settled, washed repeatedly with distilled water and ethanol three times, dried in a blast drying oven at 100°C, and ground to obtain TiO 2 powder.

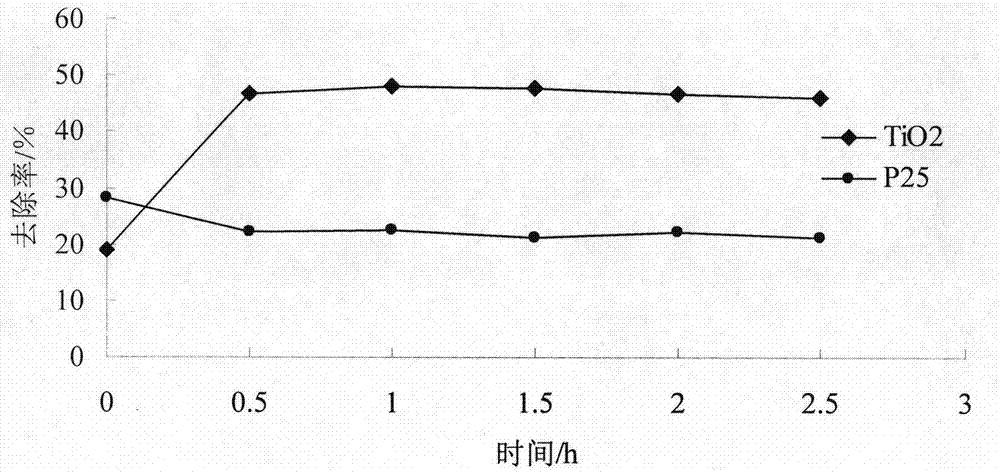

[0031] Catalyst photocatalytic activity test method: The photocatalytic activity of the catalyst was evaluated by visible light photocatalytic degradation of methylene blue solution with an initial concentration of 20mg / L. The specific steps are: weigh 1g of catalyst powder and add it to 100mL of methylene blue solution, let it stand in the d...

Embodiment 2

[0034] ① Measure 30.4mL of absolute ethanol and add it to 35.2mL of butyl titanate, and record it as solution A;

[0035] ② Take 30.4mL of absolute ethanol and add it to 180mL of water, and add 20.2mL of HF at the same time, and record it as solution B;

[0036] ③ Add solution B to solution A drop by drop, control the drop rate at 2-3 drops per second, mix and stir at low speed for 1.5 hours to obtain TiO 2 Sol, aged at room temperature;

[0037] ④The aged 2d TiO 2 The sol was centrifugally settled, washed repeatedly with distilled water and ethanol three times, dried in a blast oven at 80°C, and ground to obtain TiO 2 powder.

[0038] The photocatalytic activity test method of the catalyst is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com