Preparation method of tert-butyl (methyl)acrylate

A technology of tert-butyl acrylate and acrylic acid, which is applied in the chemical field of preparing ester by enoic acid method, can solve the problems of low yield, equipment corrosion, large steric hindrance effect, etc., and achieves the effect of simplifying the process route and reducing the number of devices and equipment.

Inactive Publication Date: 2015-01-14

SHENZHEN FEIYANG IND CO LTD +2

View PDF3 Cites 13 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This process has problems such as equipment corrosion, side reactions and difficult disposal of reaction waste liquid.

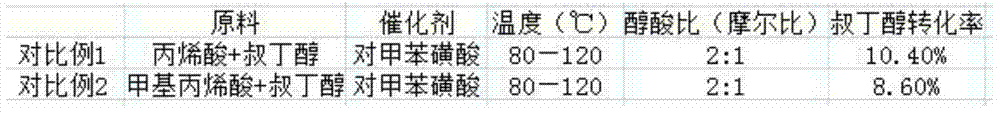

In addition, in the process of preparing tertiary alcohol esters by esterification of carboxylic acids and corresponding alcohols, because tert-butanol has a relatively large steric hindrance effect, it is more inclined to the elimination reaction in the two competing reactions of esterification and elimination, and cannot reach The purpose of esterification, so the esterification of tertiary alcohols is much more difficult than primary alcohols and secondary alcohols, and the yield of the actual reaction is very low

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0021] In the above, the acidic catalyst is a strongly acidic ion exchange resin catalyst.

Embodiment 2

[0023] In the above, the strongly acidic ion exchange resin catalyst is a macroporous sulfonic acid type cation exchange resin.

Embodiment 3

[0025] In the above, the macroporous sulfonic acid cation exchange resin is divinylbenzene cross-linked polystyrene polymer.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention provides a preparation method of tert-butyl (methyl)acrylate. (Methyl)acrylic acid and isobutylene are subjected to addition reaction under the action of an acidic catalyst to generate the tert-butyl (methyl)acrylate. The technique belongs to an ideal atomic economic reaction, simplifies the process route, and needs fewer appliances. Besides, no byproduct is generated in the whole preparation process, so the method is a low-carbon environment-friendly technique. The adopted acidic catalyst is non-toxic and harmless, so the production process is environment-friendly. Therefore, the olefine acid addition esterification method can be widely used and is suitable for substituting the alkyd esterification method.

Description

technical field [0001] The invention relates to the field of chemical industry for preparing esters by an alkenoic acid method, in particular to a method for preparing tert-butyl (meth)acrylate. Background technique [0002] Tert-butyl (meth)acrylate is a very important chemical basic raw material and intermediate, because of its unique and highly active polar molecules, unsaturated double bonds and carboxylate (-COOR) structure, it can be Many kinds of polymer formulas with good properties are derived, and plastic, cross-linked and other polymers are prepared through emulsion polymerization, solution polymerization, copolymerization and other processing methods. It can also be self-polymerized or copolymerized with other vinyl monomers, such as styrene, vinyl acetate, methyl methacrylate, acrylonitrile, acrylamide, vinyl chloride, etc. The polymer obtained by polymerizing the carbon-carbon double bond of (meth) tert-butyl acrylate is colorless and transparent, and has exce...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C07C69/54C07C67/04B01J31/10

CPCC07C67/04B01J31/10B01J2231/49

Inventor 肖增钧姜雄彭威蒋兵吴妃飞

Owner SHENZHEN FEIYANG IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com