Photocatalytic material polyimide, as well as preparation method and applications thereof

A technology of photocatalytic materials and polyimide, which is applied in the field of photocatalytic materials, can solve the problems of non-environmental protection and few types of preparation processes, and achieve the effects of avoiding metal ion pollution, simple operation, and environmentally friendly and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

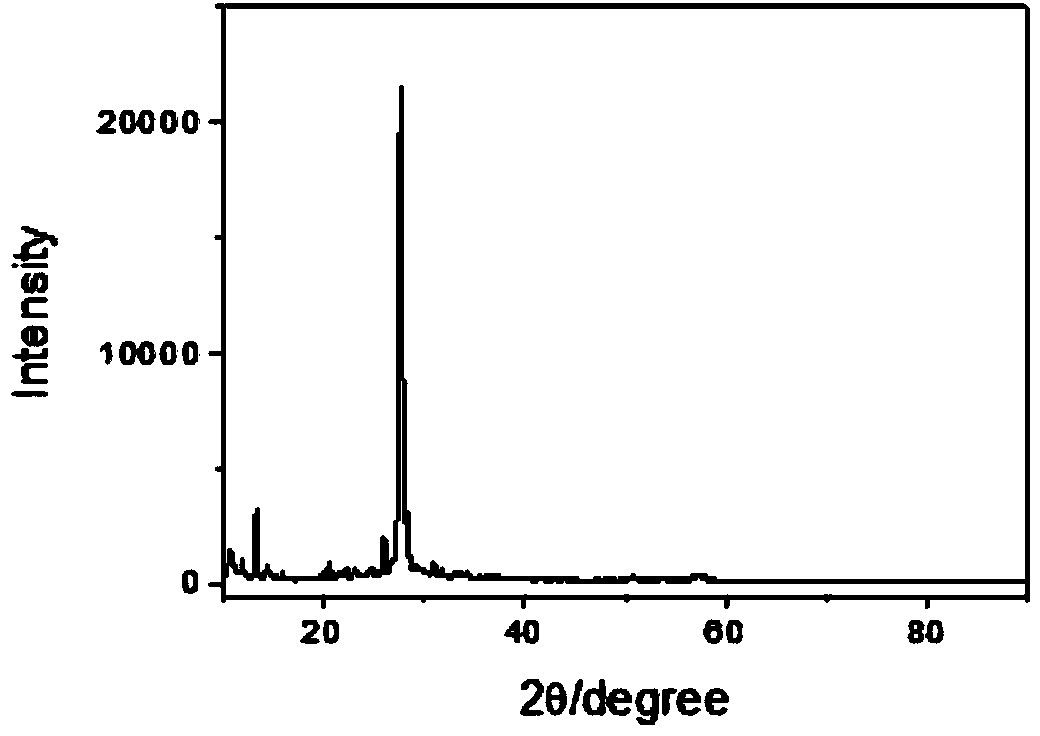

[0035] Add 0.9343g (0.015mol) ethylene glycol and 5mL DMF into the autoclave, then add 3.2703g (0.015mol) pyromellitic dianhydride (PMDA) white powder, stir evenly, then heat to 180°C for esterification, and cool to room temperature Then add 1.2602g (0.010mol) melamine to it and react at a constant temperature of 180°C for 72 hours. After cooling to room temperature, stir and wash with acetone and distilled water respectively, and finally filter and dry to obtain a polyimide photocatalytic material. The XRD patterns of polyimide photocatalytic materials are as follows: figure 1 shown. In the XRD pattern of PI, there appeared several new peaks that did not exist in the monomer, such as the peak at 2θ=13.35° and the strong peak at 2θ=27.76°. Among them, the strong peak at 2θ=27.76° corresponds to the interlayer spacing of 0.356nm between two-dimensional structures, and C 3 N 4 The interlayer spacing is close, indicating the formation of a two-dimensional covalent structure of...

Embodiment 2

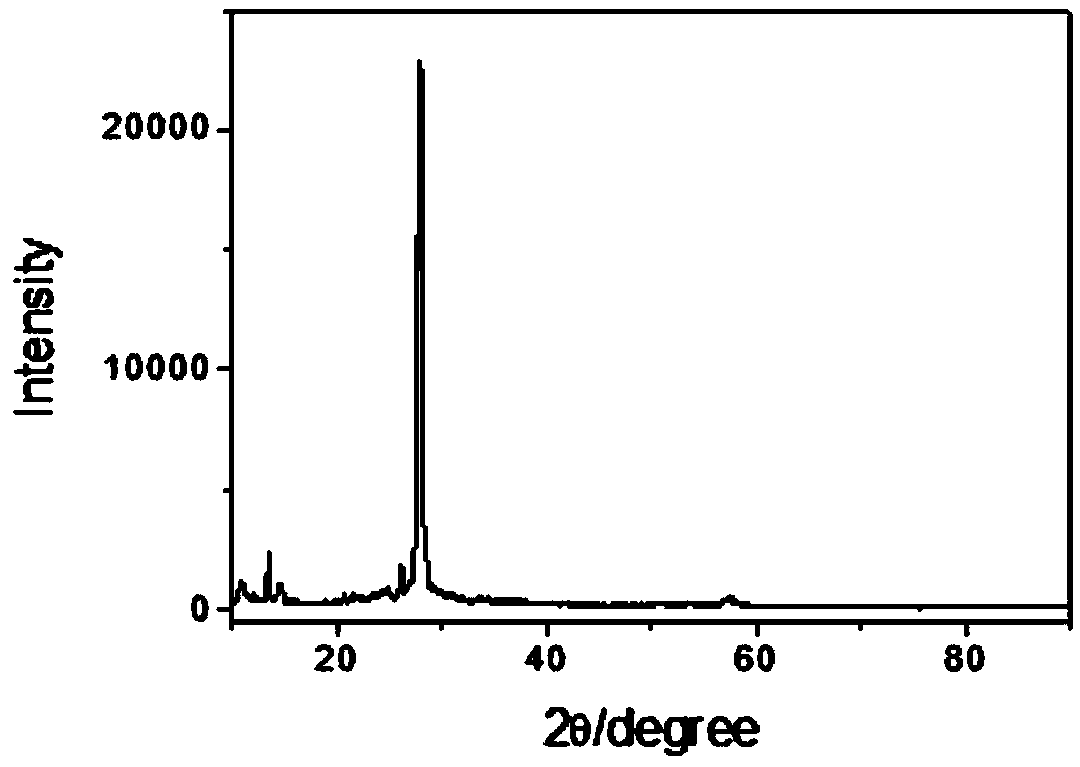

[0037] Add 2.7906g (0.045mol) ethylene glycol and 5mL DMF into the autoclave, then add 3.2703g (0.015mol) pyromellitic anhydride white powder and stir evenly, then heat to 180°C for esterification, cool to room temperature and add 1. 2602g (0.010mol) of melamine was reacted at a constant temperature of 180°C for 72 hours, cooled to room temperature, stirred and washed with acetone and distilled water respectively, and finally filtered and dried to obtain a polyimide photocatalytic material. The XRD patterns of polyimide photocatalytic materials are as follows: figure 2 shown. The XRD patterns of PI showed strong peaks at 2θ=13.4° and 2θ=27.92°. Among them, the strong peak at 2θ=27.92° corresponds to the interlayer spacing of 0.354nm between the two-dimensional structures, and C 3 N 4 Layer spacing is closer.

Embodiment 3

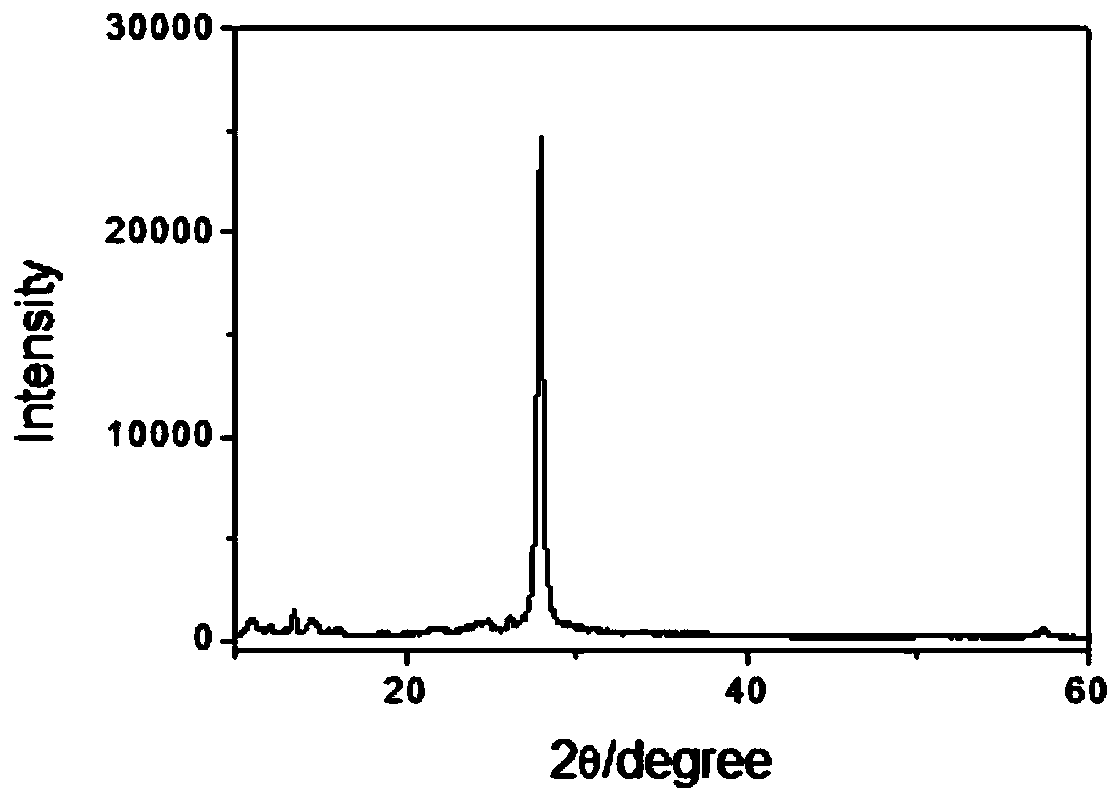

[0039] Add 5.5811g (0.090mol) ethylene glycol and 5mL DMF into the autoclave, then add 3.2703g (0.015mol) pyromellitic anhydride white powder and stir evenly, then heat to 180°C for esterification, cool to room temperature and add 1. 2602g (0.010mol) of melamine was reacted at a constant temperature of 180°C for 72 hours, cooled to room temperature, stirred and washed with acetone and distilled water respectively, and finally filtered and dried to obtain a polyimide photocatalytic material. The XRD patterns of polyimide photocatalytic materials are as follows: image 3 As shown, the SEM and TEM of polyimide photocatalytic materials are shown as Figure 4 and Figure 5 As shown, it can be seen from the microstructure that the material has a polymerized sheet structure.

[0040] Put 0.2g of the synthesized polyimide photocatalytic material into a 400mL quartz photocatalytic reactor, add 360mL of deionized water, 40mL of methanol as a sacrificial agent and 0.550mL of chloroplatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com