A kind of smelting method of low-silicon and high-titanium welding wire steel

A smelting method and high-titanium technology, applied in the field of smelting steel for low-silicon and high-titanium welding wire, can solve the problems of serious nozzle nodules and poor surface quality of continuous casting billets, reduce the amount of silicon returned, and ensure the surface quality of casting billets , to ensure the effect of pourability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

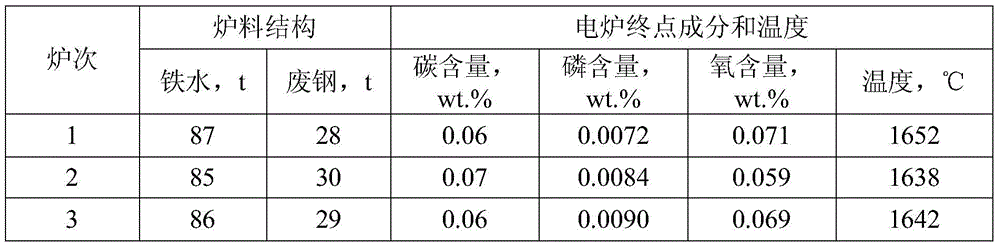

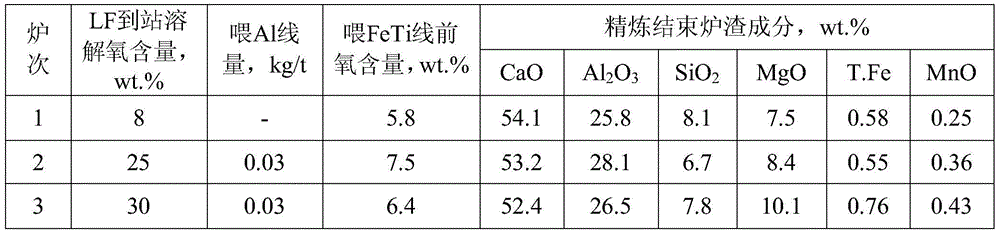

[0016] The inventor of the present case used the smelting method of the present invention to continuously produce 3 furnaces with 140mm×140mm section continuous casting billets in a steelmaking workshop, including the 110t electric furnace smelting process, the ladle refining process and the small billet continuous casting process. The nodule phenomenon, the specific process method is as follows:

[0017] 1) In the electric furnace smelting process, the charge structure includes molten iron and scrap steel, wherein the molten iron accounts for 65-80wt.% of the total charge; when the carbon content in the molten pool is 0.05-0.08wt.%, the phosphorus content is ≤0.01wt. When the temperature is ≥1630℃, the steel can be tapped; when the tapping amount is 15-20wt.%, the alloy and slag are added in the order of "aluminum ingot→silicon manganese→low carbon ferromanganese→nickel plate→lime", among which the amount of aluminum ingot added It is 1.0~1.2kg / t, the addition amount of silic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com