Composite copper electrode ceramic positive temperature coefficient thermistor and its preparation process

A positive temperature coefficient and thermistor technology, applied in resistors with positive temperature coefficient, coating resistance materials, etc., can solve the problems of inability to provide cost-effective products, lengthy silver sintering process, and high cost of silver electrodes. Achieve the effect of green environmental protection process, shorten the preparation time and solve the oxidation problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

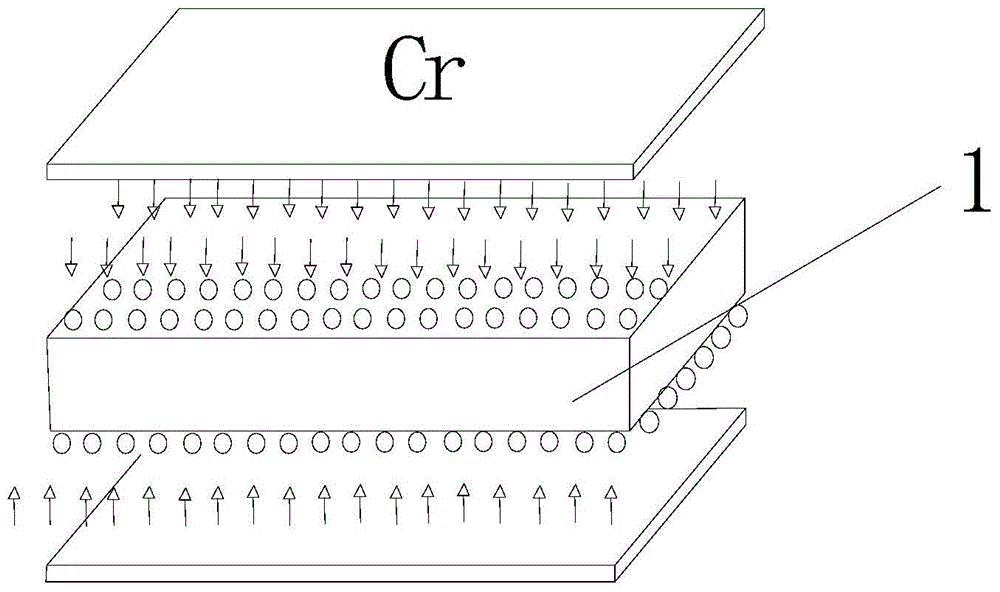

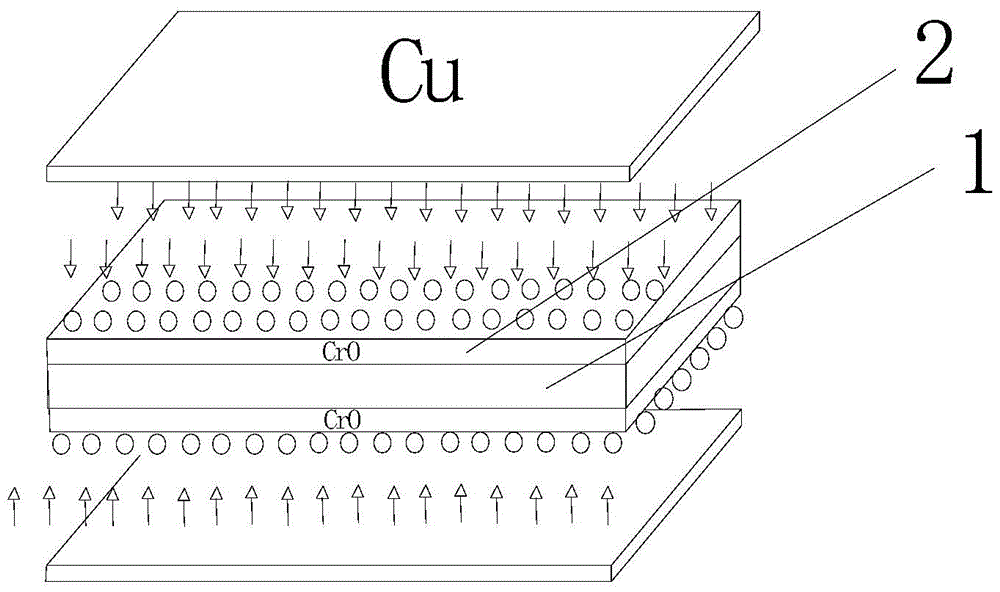

[0019] The present invention will now be described in further detail in conjunction with the accompanying drawings and preferred embodiments. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

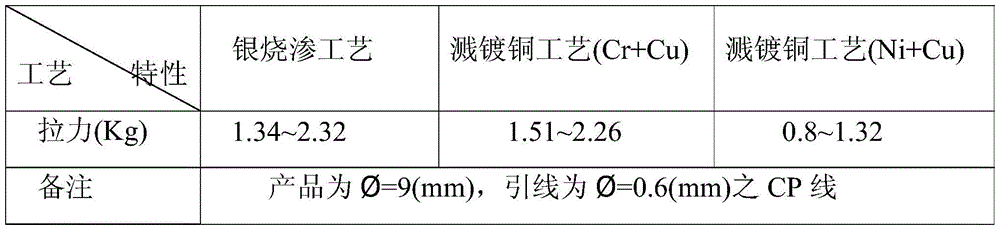

[0020] Such as figure 1 , 2 As shown, after the sintered ceramic body of CPTCR is pre-treated on the surface before sputtering, and after adjusting the appropriate power parameters, the bottom electrode layer is vacuum sputtered with Cr metal to make it sputter on the surface of the CPTCR ceramic body. During the process, the Cr metal Capture the oxygen atoms on the surface of the ceramic body, in addition to forming an Ohmic contact, on the other hand, combine oxygen atoms to form a chromium oxide ceramic body structure with a high degree of fit with the metal stack, as a transition layer connecting two heterogeneous mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com