Polyester composite film applied to extrusion coating type packaging bags and preparation method of polyester composite film

A polyester composite film and packaging bag technology, applied in chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve the problem of broken bags, low composite fastness of PET layer and PE layer, and inability to meet the requirements of retort bags. Demand and other issues, to achieve high composite fastness, avoid solvent-based adhesives, and use less raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

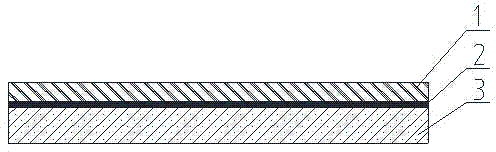

[0029] Such as figure 1 As shown, a polyester composite film for extrusion coating packaging bags is composed of a substrate layer 1, a crosslinking agent layer 2 and a hot melt layer 3, wherein the material of the substrate layer 1 is biaxially stretched polyester In the film, the material of the cross-linking agent layer 2 is a water-based primer curing cross-linking agent, and the material of the hot-melt layer 3 is high-density polyethylene. The cross-linking agent layer 2 is coated on the corona-treated surface of the biaxially stretched polyester film, and after drying, the melt-extruded high-density polyethylene is coated on the cross-linking agent layer 2 to form a hot-melt layer 3, that is, cross-linking agent layer 2 The linking agent layer 2 is located between the substrate layer 1 and the hot-melt layer 3, and the crosslinking agent layer 2 is in contact with the surface of a biaxially stretched polyester film with a surface wetting tension of 56-62 dyn and a rough...

Embodiment 2

[0038] 1) Biaxially stretched polyester film with high surface wetting tension is selected as the substrate layer, and the surface is corona treated;

[0039] 2) Coat the corona-treated surface of the biaxially oriented polyester film with a water-based primer curing cross-linking agent solution, and then enter it into an oven at 60°C for 0.5 seconds;

[0040] 3) High-density polyethylene is melted at a high temperature of 330°C and extrusion coated on the surface of a biaxially oriented polyester film coated with a water-based primer curing crosslinking agent;

[0041] 4) After laminating, the cold roll and the back pressure roll are cooled and pressed together, then trimmed, pulled and rolled up to obtain a finished polyester composite film with a three-layer structure. The temperature of the cold roll is 12°C.

[0042]

Embodiment 3

[0044] 1) Biaxially stretched polyester film with high surface wetting tension is selected as the substrate layer, and the surface is corona treated;

[0045] 2) Coat the corona-treated surface of the biaxially oriented polyester film with a water-based primer curing cross-linking agent solution, and then enter it into an oven at 80°C for 1 second;

[0046] 3) High-density polyethylene is melted at a high temperature of 310°C and extrusion coated on the surface of a biaxially oriented polyester film coated with a water-based primer curing crosslinking agent;

[0047] 4) After laminating, the cold roll and the back pressure roll are cooled and pressed together, then trimmed, pulled and rolled up to obtain a finished polyester composite film with a three-layer structure. The temperature of the cold roll is 9°C.

[0048]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com