Controlled-release carrier and application of controlled-release carrier in controlled release of moisture and fertilizer required for potted crops

A slow-release carrier, fertilizer technology, applied in the application, matrix fertilizer, fertilizer mixture and other directions, can solve problems such as poor growth of potted crops, inability to take care of potted crops, adverse environmental effects, etc., and achieves storage stability promotion, good control, and storage. The effect of more water and nutrients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

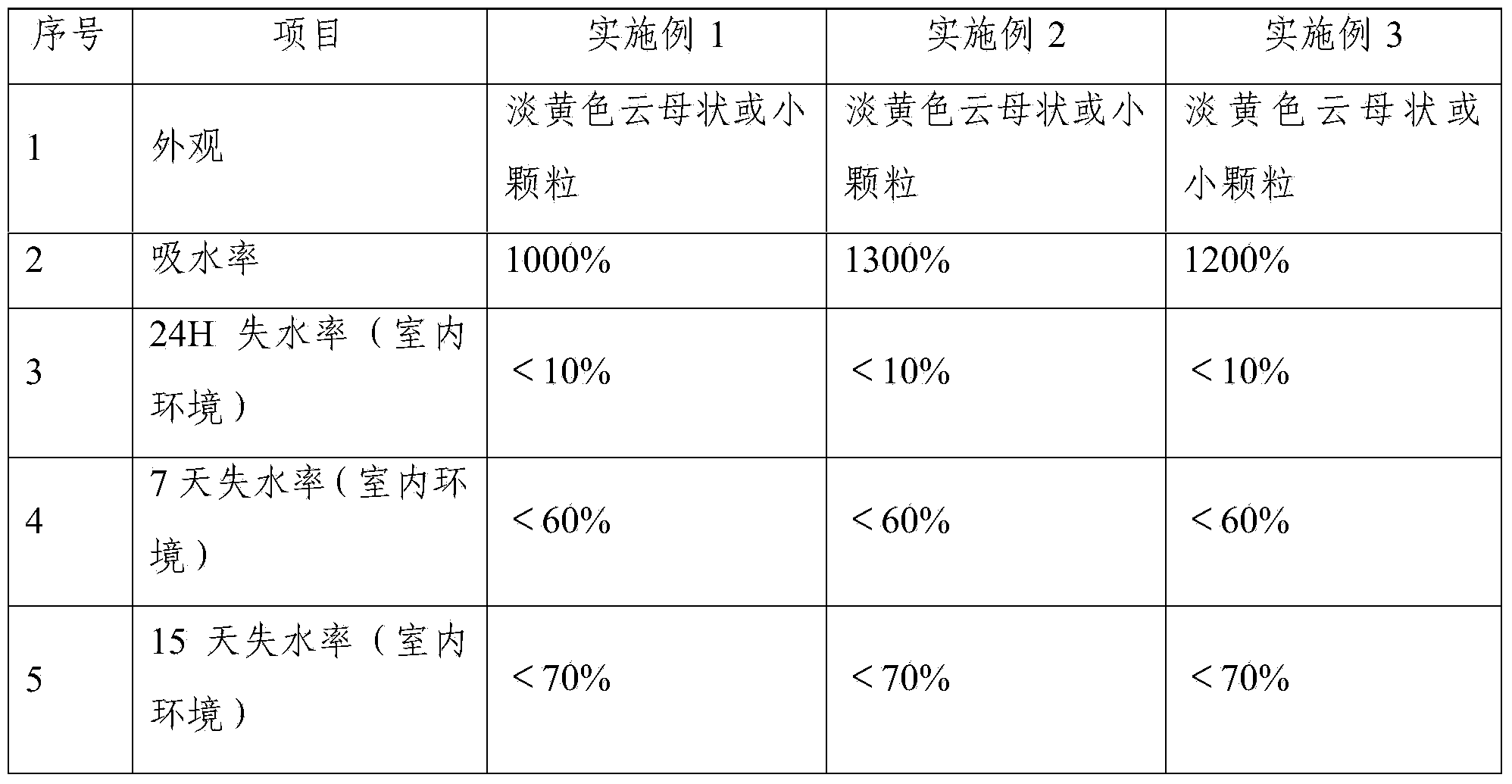

Embodiment 1

[0025] The preparation example of embodiment 1 sustained-release carrier

[0026] The raw materials are as follows: 100 parts of corn starch, 30 parts of polyethylene glycol, 15 parts of pasting agent sodium hydroxide, 25 parts of etherification agent propylene oxide, 201 parts of Tween, 1 part of stabilizer sodium carboxymethyl cellulose, 300 parts of water, 15 parts of glycerin, 0.5 parts of ammonium sulfate;

[0027] Prepare the slow-release carrier as follows:

[0028] 1) Mix the starch and gelatinizer, add water to it, stir at room temperature, gelatinize the starch emulsion, then add etherification agent, raise the temperature to 40-50°C, and keep stirring for 30 minutes;

[0029] 2) Add polyethylene glycol, glycerol, Tween-20, and water to form a solution with a solid content of 30-40% (by weight), stir for 20 minutes, add a catalyst therein, heat up to 70°C, and stir for 1 Hour;

[0030] 3) Add a stabilizer to the above-mentioned product, throw it into a multi-rolle...

Embodiment 2

[0031] The preparation example of embodiment 2 sustained-release carrier

[0032] The raw materials are as follows: 100 parts of potato starch, 50 parts of polyethylene glycol, 20 parts of pasting agent sodium carbonate, 35 parts of etherification agent propylene oxide, 205 parts of Tween, 5 parts of stabilizer sodium carboxymethyl cellulose, water 400 parts, 25 parts of glycerol, 0.5 part of ammonium sulfate;

[0033] Prepare the slow-release carrier as follows:

[0034] 1) Mix the starch and gelatinizer, add water to it, stir at room temperature, gelatinize the starch emulsion, then add etherification agent, raise the temperature to 40-50°C, and keep stirring for 30 minutes;

[0035] 2) Add polyethylene glycol, glycerin, Tween-20, and water, stir for 20 minutes, add a catalyst therein, raise the temperature to 90°C, and stir for 1 hour;

[0036] 3) Add a stabilizer to the above-mentioned product, put it into a multi-roller dryer for gelatinization, dry, control the tempera...

Embodiment 3

[0037] The preparation example of embodiment 3 sustained-release carrier

[0038] The raw materials are as follows: 100 parts of tapioca starch, 40 parts of polyethylene glycol, 18 parts of pasting agent sodium hydroxide or sodium carbonate, 30 parts of etherification agent propylene oxide, 204 parts of Tween, stabilizer sodium carboxymethyl cellulose 4 parts, 350 parts of water, 20 parts of glycerin, 0.5 parts of ammonium sulfate;

[0039] Prepare the slow-release carrier as follows:

[0040] 1) Mix the starch and gelatinizer, add water to it, stir at room temperature, gelatinize the starch emulsion, then add etherification agent, raise the temperature to 40-50°C, and keep stirring for 30 minutes;

[0041] 2) Add polyethylene glycol, glycerin, Tween-20, and water, stir for 20 minutes, add a catalyst therein, raise the temperature to 80°C, and stir for 1 hour;

[0042] 3) Add a stabilizer to the above-mentioned product, throw it into a multi-roller dryer for gelatinization, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com