A method for separating and purifying methane containing hydrogen and carbon monoxide to produce liquefied natural gas

A technology for liquefied natural gas and carbon monoxide, which is used in the separation of methane-rich gas and the chemical industry to achieve the effects of large processing capacity, high operating flexibility and convenient circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

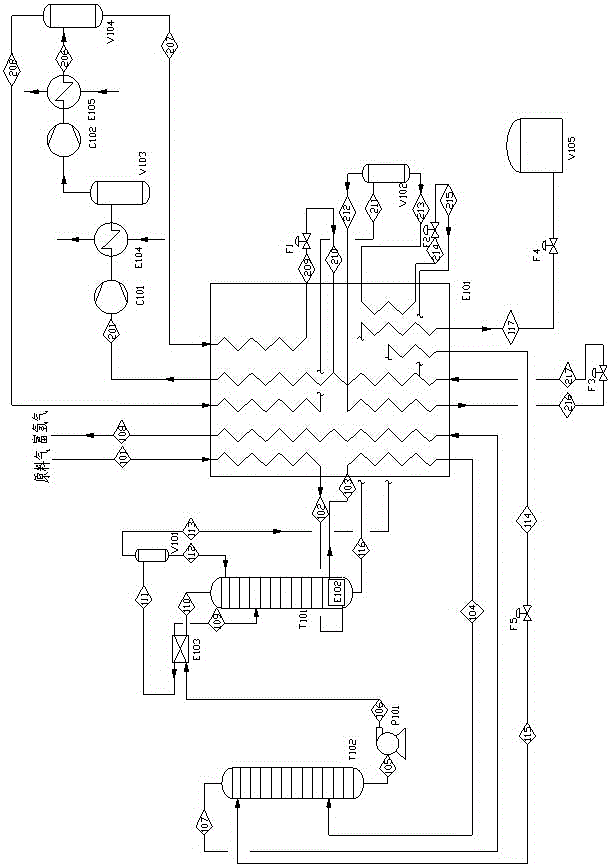

[0054] The flow chart of this embodiment is as figure 1 As shown, the nitrogen-containing methane gas listed in this embodiment is purified coke oven gas. The process steps of using the gas to produce liquefied natural gas (LNG) and hydrogen-rich gas through double-tower rectification are as follows.

[0055] (1) Raw material gas pre-cooling

[0056] The raw material gas 101 enters the liquefaction device, and the raw material gas 101 is first condensed in the condensing evaporator E101 to a liquid state or partially condensed to a liquid state to obtain the primary cooling raw material 102. The primary cooling raw material 102 is sent to the kettle reboiler E102 of the high-pressure tower T101 to provide heat, while the primary cooling raw material 102 is cooled, and the cooled primary cooling raw material 103 enters the condensing evaporator E101 of the liquefaction unit for deep cooling. It is cooled to a full liquid state, and a cryogenic raw material gas 104 is obtained.

[00...

Embodiment 2

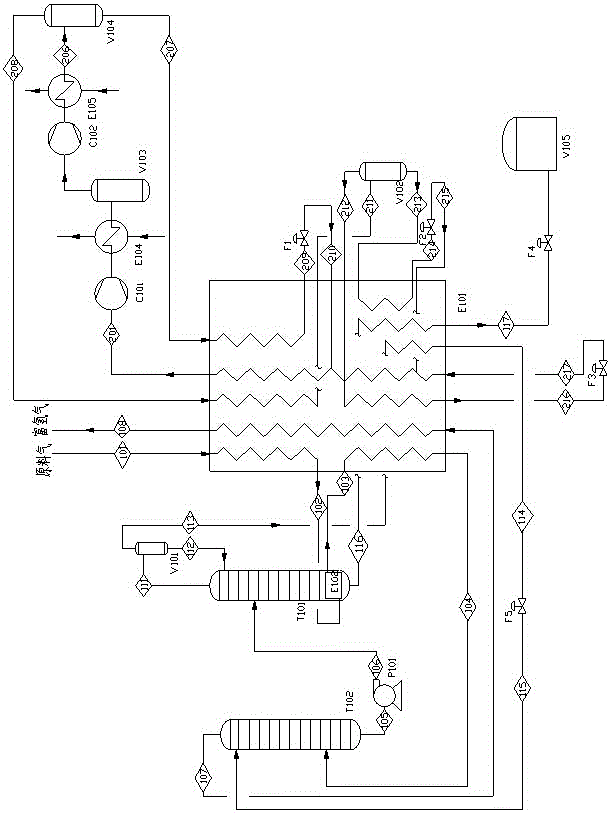

[0076] The flow chart of this embodiment is as figure 2 As shown, the nitrogen-containing methane gas enumerated in this embodiment is purified coke oven gas, and the process steps of using this gas to produce liquefied natural gas (LNG) and hydrogen-rich gas through double-tower rectification are as follows.

[0077] (1) Raw material gas pre-cooling

[0078] The raw material gas 101 is first condensed to nearly liquid or partially condensed to liquid in the condensing evaporator E101 to obtain the primary cooling raw material 102. The primary cooling raw material 102 is sent to the kettle reboiler E102 of the high-pressure tower T101 to provide heat, while the primary cooling raw material 102 is cooled, and the cooled primary cooling raw material 103 enters the condensing evaporator E101 of the liquefaction unit for deep cooling. It is cooled to a full liquid state, and a cryogenic raw material gas 104 is obtained.

[0079] (2) Low pressure column T102 distillation

[0080] The cry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com