Method for improving homogeneity of potassium tantalate niobate crystal through double-crucible real-time material-feeding technology

A technology of potassium tantalum niobate and double crucibles is applied in the research field of preparation technology of functional crystal materials, which can solve the problems of difficulty in taking into account crystal size and uniformity, difficulty in obtaining modulation effect, fluctuation in crystal composition, etc., and simplify the ratio of raw materials. Design, avoid fluctuations in growth temperature and melt composition, reduce the effect of fluctuations in crystal composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

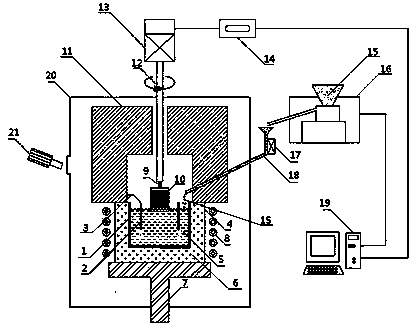

Method used

Image

Examples

Embodiment 1

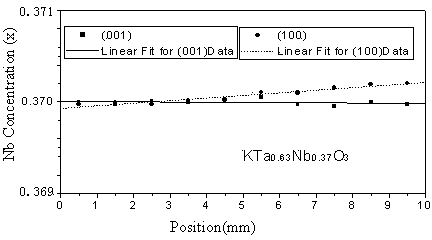

[0029] Example 1: KTa 0.63 Nb 0.37 o 3 Crystal Growth Preparation

[0030] Since KTN crystal has significantly superior electro-optical and other physical properties near the phase transition point, while KTa 0.63 Nb 0.37 o 3 The Curie phase transition point of the crystal is near room temperature, which is beneficial to the development and design of KTN electro-optic components that can be applied at room temperature. The crystal preparation process is as follows: take high-purity K 2 CO 3 (purity 99.99%), high-purity Ta 2 o 5 (purity 99.99%), high-purity Nb 2 o 5 (Purity 99.99%) The raw materials are weighed according to the molar ratio of 1.25:0.3:0.7, mixed evenly and in 10 8 Compacted into blocks under Pa, sintered at 1050°C for 24 hours to obtain KTa 0.63 Nb 0.37 o 3 Base material, at this time the base material is block. K 2 CO 3 : Ta 2 o 5 :Nb 2 o 5 Weigh according to the molar ratio 1:0.63:0.37, mix well and 8 Compacted into blocks under Pa, sint...

Embodiment 2

[0033] Example 2: KTa 0.9 Nb 0.1 o 3 Crystal Growth Preparation

[0034] The process of this embodiment is the same as that of Embodiment 1, but the specific parameters need to be adjusted as follows, the ratio of base material and supplementary material is adjusted to K 2 CO 3 : Ta 2 o 5 :Nb 2 o 5 =1.25:0.72:0.28 and 1:0.9:0.1; the sintering temperature of the base material and the supplementary material is adjusted to 1090°C and 1100°C respectively, the full melting point of the crystal growth stage is 1275°C, overheating, planting, shouldering and so on The diameter growth temperature is adjusted to 1375°C, 1275°C, 1265°C, 1270°C, and the cooling rate at the end of crystal growth can be increased to 45°C / h to room temperature.

Embodiment 3

[0035] Example 3: KTa 0.75 Nb 0.25 o 3 Crystal Growth Preparation

[0036] The process of this embodiment is basically the same as that of Embodiment 1. The specific parameters are adjusted as follows, and the ratio of base material and supplementary material is adjusted to K 2 CO 3 : Ta 2 o 5 :Nb 2 o 5 =1.25:0.43:0.57 and 1:0.75:0.25; the sintering temperature of the base material and the supplementary material is adjusted to 1050°C and 1080°C respectively, the full melting point of the crystal growth stage is 1225°C, overheating, planting, shouldering and so on The diameter growth temperature was adjusted to 1325°C, 1225°C, 1215°C, 1220°C, and the cooling rate at the end of crystal growth was adjusted to 35°C / h to room temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com