A temperature-resistant emulsion sizing agent for carbon fiber and its preparation method and application

A technology of carbon fiber and sizing agent, which is applied in the fields of carbon fiber, fiber treatment, textiles and papermaking, etc., which can solve the problems of difficult emulsification and high rigidity of sizing agents, and achieve the effects of easy implementation, improved performance and stable properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

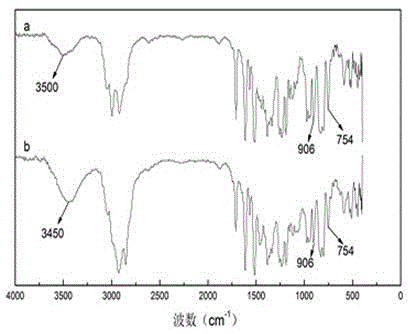

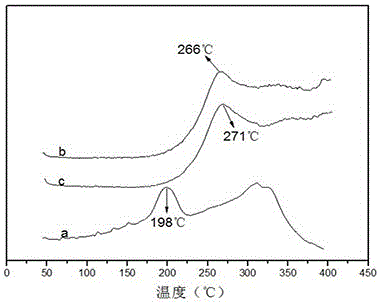

[0047] Synthesis of modified epoxy resin: Add the acetone solution of p-aminophenol epoxy resin (AFG-90) into a three-hole flask equipped with a condensing reflux device, stir at a constant speed of 30°C for 20min, and heat up to 70°C after AFG-90 dissolves evenly. Then, the acetone solution of n-dodecylamine was added dropwise into the three-necked flask, and stirred and reacted at constant temperature for 2.5 hours to obtain modified AFG-90. In the above reaction, the mass ratio of n-dodecylamine to AFG-90 is 20:80, the mass ratio of AFG-90 to acetone is 60:40, and the mass ratio of n-dodecylamine to acetone is 20:80.

[0048] Preparation of sizing agent: preheat the emulsifier NP-10 and Nongru 1601 in a ratio of 50:50, and the penetrant secondary octanol polyoxyethylene ether (JFC-2) to 50°C and stir evenly, then add the above-mentioned main slurry to modify AFG-90. Then, add diluent acetone into the above mixture and stir evenly. The quality of the emulsifier is 10% of t...

Embodiment 2

[0052] Synthesis of modified epoxy resin: Add the acetone solution of 4,4-diaminoxylene methane epoxy resin (AG-80) into a three-hole flask equipped with a condensation reflux device, stir at a constant speed of 40°C for 20 minutes, and AG-80 dissolves evenly Afterwards, the temperature was raised to 95° C., and then the acetone solution of n-dodecylamine was added dropwise into the three-necked flask, and the reaction was stirred at constant temperature for 3 hours to obtain modified AG-80. In the above reaction, the mass ratio of n-dodecylamine to AG-80 is 20:80, the mass ratio of AG-80 to acetone is 70:30, and the mass ratio of n-dodecylamine to acetone is 35:65.

[0053] Preparation of sizing agent: Preheat the emulsifier NP-10 and EL-20 in a ratio of 40:60, and the penetrant secondary octanol polyoxyethylene ether (JFC-2) to 30°C and stir evenly, then add the above-mentioned main slurry to modify AG-80. Then, add diluent methyl ethyl ketone into the above mixture and sti...

Embodiment 3

[0057] Synthesis of modified epoxy resin: Add the acetone solution of AFG-90 into a three-hole flask equipped with a condensing reflux device, stir at a constant speed at 50°C for 20 minutes, and heat up to 110°C after AFG-90 dissolves evenly, and then add positive The acetone solution of dodecylamine was stirred at constant temperature for 3.5 hours to obtain modified AFG-90. In the above reaction, the mass ratio of n-dodecylamine to AFG-90 is 15:85, the mass ratio of AFG-90 to acetone is 40:60, and the mass ratio of n-dodecylamine to acetone is 40:60.

[0058] Preparation of sizing agent: preheat the emulsifier Nongru 1601 and EL-20 in a ratio of 10:90, and the penetrant secondary octanol polyoxyethylene ether (JFC-2) to 55°C and stir evenly, then add the above-mentioned main slurry to modify AFG-90. Then, add the diluent methyl ethyl ketone into the above mixture and stir evenly, the quality of the emulsifier is 8% of the main slurry quality, the quality of the penetrant i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com