Organic monolayer thin film field effect gas sensor and preparation method thereof

A technology of gas sensor and thin film field effect, which is applied in the direction of instruments, scientific instruments, analytical materials, etc. It can solve the problems of inability to achieve high response efficiency and long response time of sensors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

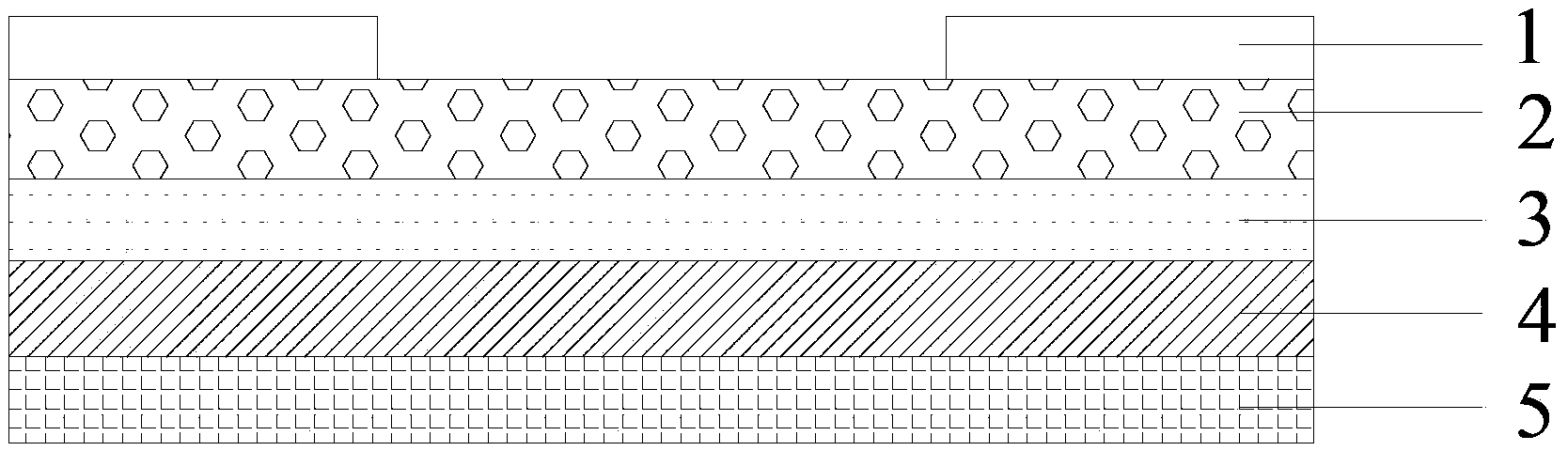

[0044] A preparation method of the gas sensor, the preparation method adopts a vacuum evaporation method to evaporate an organic monomolecular thin film layer on the dielectric layer 3; during evaporation, the evaporation source is first heated to a target temperature (such as 123°C ), after the deposition rate is stable, turn on the beam baffle to start evaporation; the evaporation rate is selected appropriately (such as 1.5nm / min), the purpose is to ensure that the evaporated molecular layer grows in a two-dimensional growth mode, and control the evaporation time (such as 1min) to obtain an organic monomolecular thin film layer as the active layer 2.

[0045] The metal foil used as the source-drain electrode 1 is directly attached to the surface of the organic monomolecular film layer by mechanical means.

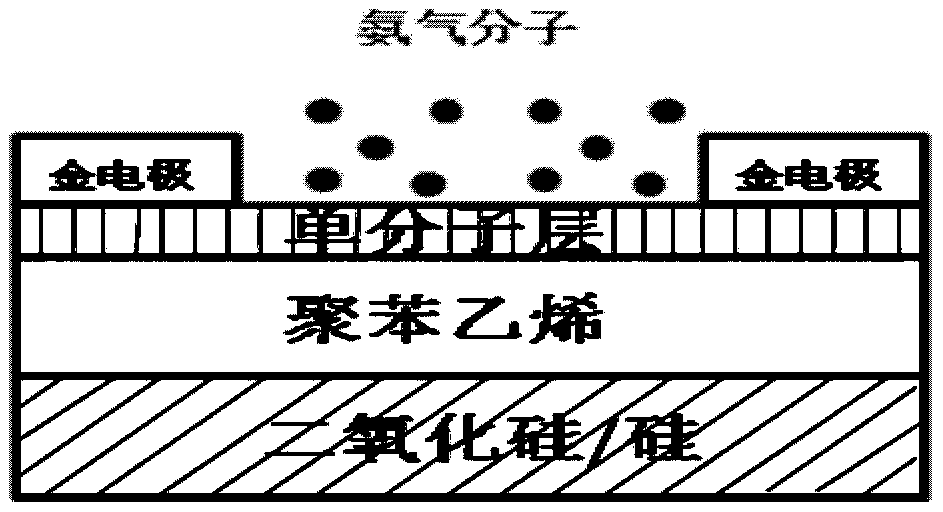

[0046] Specifically, a preparation such as figure 2 The main process of the organic monolayer thin film field-effect gas sensor shown is as follows:

[0047] (1) In Si / S...

specific Embodiment 1

[0052] Select the Si / SiO2 sheet purchased from Hefei Kejing Material Technology Co., Ltd. as the substrate, cut it into a size of about 1×1cm, use acetone, ethanol, and deionized water to clean it ultrasonically for 10 minutes, and then use a hot stage at 100°C Bake for 2h. Spin coating after drying. The spin coating process is completed on the laurell WS-400MZ-8NPP-LITE spin coater. The substrate is adsorbed on the spin coater, and the speed is set at 6000 / min. The solution is dropped on the surface of the substrate, the solution is required to cover the substrate, and the spin coating is started. After the spin coating is completed, the sample is placed in a vacuum drying oven, and the baking temperature is set to 85° C., and baked for 12 hours.

[0053] After the sample is dried, the key step of evaporation of the organic active layer is carried out. This process is completed on the auto306 vacuum evaporation equipment of BOC-Edwards Company. After loading the crucible wi...

specific Embodiment 2

[0056] Specific embodiment 2 (comparative example)

[0057] A field-effect gas sensor with an organic active layer thickness of 40 nm was prepared. The preparation method was described in Example 1, except that the vapor deposition time of pentacene was appropriately prolonged to obtain an active layer with a film thickness of 40 nm. The prepared 40nm thick film sensor is tested for ammonia molecules, and the test results are compared with the test results of the monomolecular layer sensor in Example 2. The specific comparison method is: source and drain of the two sensors in different concentrations of ammonia gas Changes in current are compared. It is found that the source-drain current of the monolayer sensor has a more obvious change with the concentration of ammonia gas, indicating that the monomolecular layer sensor has higher sensitivity than the thick film sensor. The whole test result is as Figure 5 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com