Artificial skin and preparation method thereof

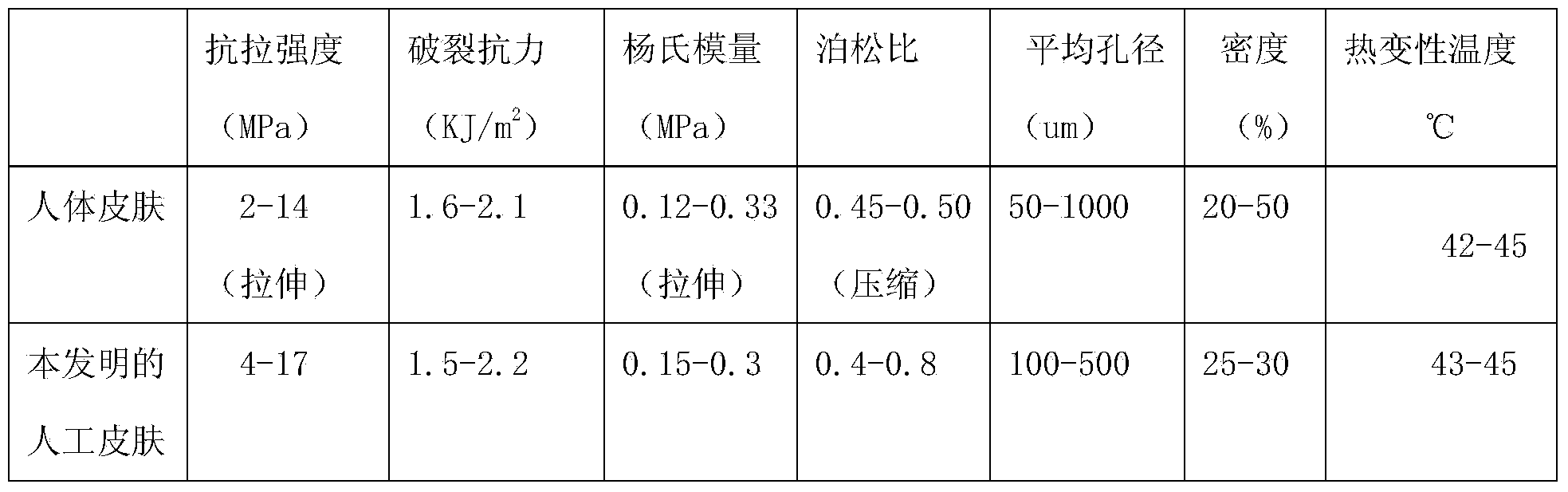

A technology of artificial skin and treatment method, applied in medical science, prosthesis, etc., can solve the problems of increased acidity of surrounding tissue, insufficient strength, increased repair and regeneration of connective tissue, etc., and achieves simple preparation process, short production cycle and long storage time long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Prepare artificial skin, its step comprises:

[0021] Take the bovine tendon material, clean it, cut it into small pieces, soak it with a mixed aqueous solution of 0.05% peracetic acid and 1% ethanol for 10 minutes, and use absolute ethanol to soak the bovine tendon material once at room temperature. First soak for 3 hours; fully mash the soaked material, soak in 0.2% pepsin solution for 12 hours for soaking treatment, the mass volume ratio of material to solution is 1:20 (g / ml); add 30% concentrated brine Carry out salting out. Centrifuge at 4000g for 30min. The precipitate was dissolved in 0.1% acetic acid, placed in a dialysis bag and dialyzed against 1 mol / L HCL for 5 hours. Phosphate buffer was used to adjust the pH value of the collagen solution system to 5.0, and the final concentration of the collagen solution was 0.2%. The solution was placed in an ultrasonic oscillator, and the temperature was adjusted to 20° C. and the frequency was 20 Hz. Then use sodium ...

Embodiment 2

[0023] Prepare artificial skin, its step comprises:

[0024] Take the bovine tendon material, clean it up, and cut it into small pieces, soak it with a mixed aqueous solution of 5% peracetic acid and 15% ethanol for 60 minutes, and use sodium carbonate solution to soak the bovine tendon material at room temperature for 5 times. First soak for 3 hours; fully mash the soaked material, soak in 5% pepsin solution for 48 hours for soaking treatment, the mass volume ratio of material to solution is 1:50 (g / ml); add 50% concentrated brine Carry out salting out. Centrifuge at 5000g for 50min. The precipitate was dissolved in 0.2% acetic acid, placed in a dialysis bag and dialyzed against 2mol / L HCL for 15 hours. Phosphate buffer solution was used to adjust the pH value of the collagen solution system to 6.5, the final concentration of the collagen solution was 1%, and placed in an ultrasonic oscillator, the temperature was adjusted to 25° C., and the frequency was 60 Hz. Then use s...

Embodiment 3

[0026] Prepare artificial skin, its step comprises:

[0027] Take the cartilage, clean it, cut it into small pieces, soak it in 0.1% sodium hydroxide solution for 4 hours, use methanol to soak the cartilage once at room temperature, and soak it for 3 hours each time; mash the soaked material fully, 0.2% pepsin solution was used for immersion treatment for 12 hours, and the mass volume ratio of material and solution was 1:20 (g / ml); 30% concentrated brine was added for salting out. Centrifuge at 4000g for 30min. The precipitate was dissolved in 0.1% acetic acid, placed in a dialysis bag and dialyzed against 1 mol / L HCL for 5 hours. Phosphate buffer was used to adjust the pH value of the collagen solution system to 5.0, and the final concentration of the collagen solution was 0.2%. The solution was placed in an ultrasonic oscillator, and the temperature was adjusted to 20° C. and the frequency was 20 Hz. Then use sodium hydroxide solution to adjust the pH value to 7.0, place i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com