Method for preparing TiO2/g-C3N4 composite visible light catalyst

A g-c3n4, visible light technology, used in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of hidden safety hazards and high operational requirements for operators, and achieve light absorption rate and photocatalytic activity. High, simple process, many photocatalytic active centers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

[0034] This embodiment prepares TiO 2 / g -C 3 N 4 The method for composite visible light catalyst comprises the following steps:

[0035] ① Precursor preparation. 20mL Ti(OBu) 4 and 20g of melamine in 500mL of ethanol at 20°C were uniformly dispersed, and then added to the Ti(OBu) containing Ti(OBu) 4 Add 50 mL of water dropwise to ethanol containing melamine to obtain a mixed material; evaporate the mixed material to dryness in a water bath at 70°C to 85°C (80°C in this example) under stirring to obtain a precursor 。

[0036] ② Transfer the precursor prepared in step ① to a muffle furnace, and calcinate it at 520 °C for 2 hours in the muffle furnace to obtain TiO 2 / g -C 3 N 4 Composite visible light catalyst.

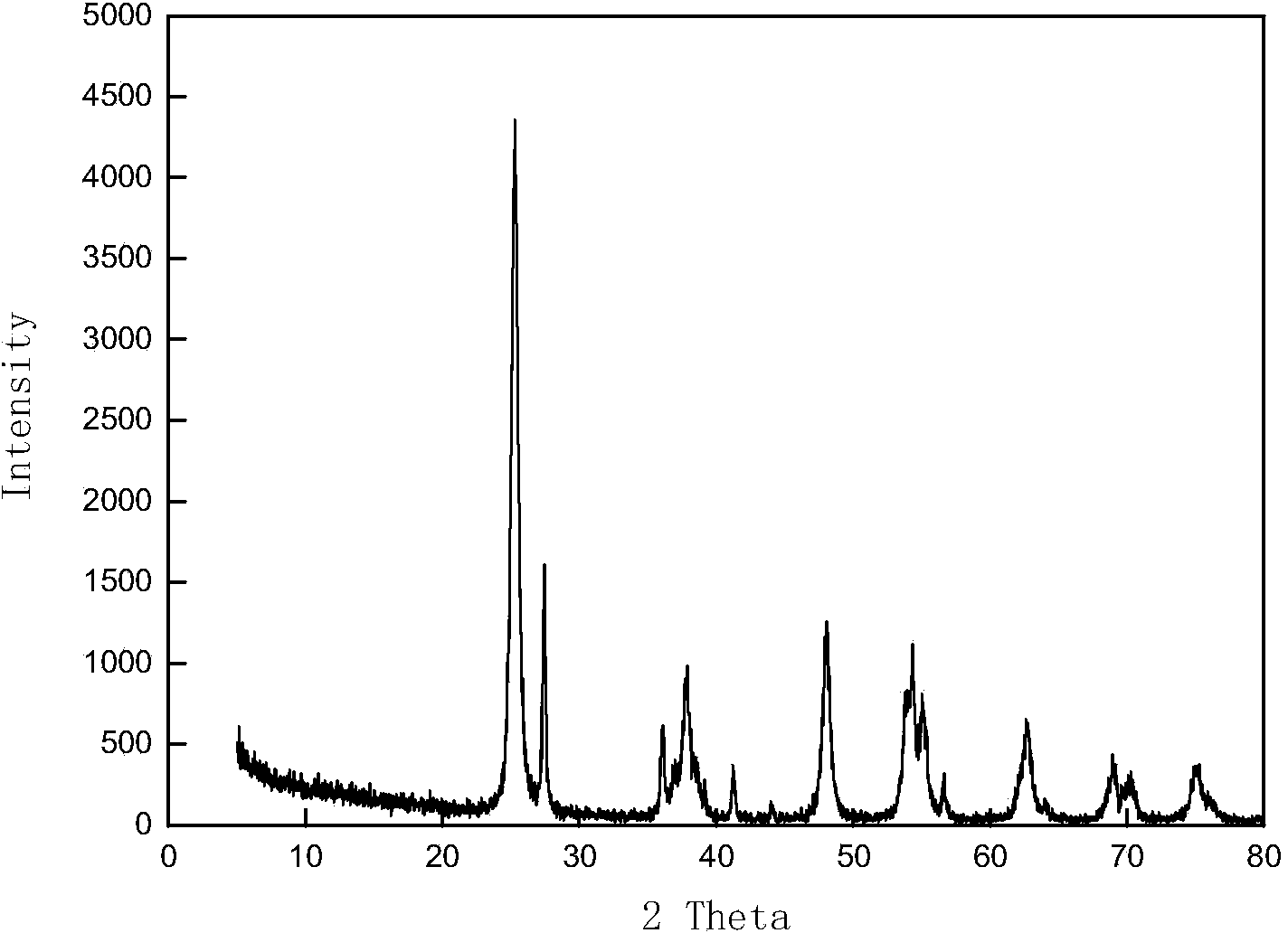

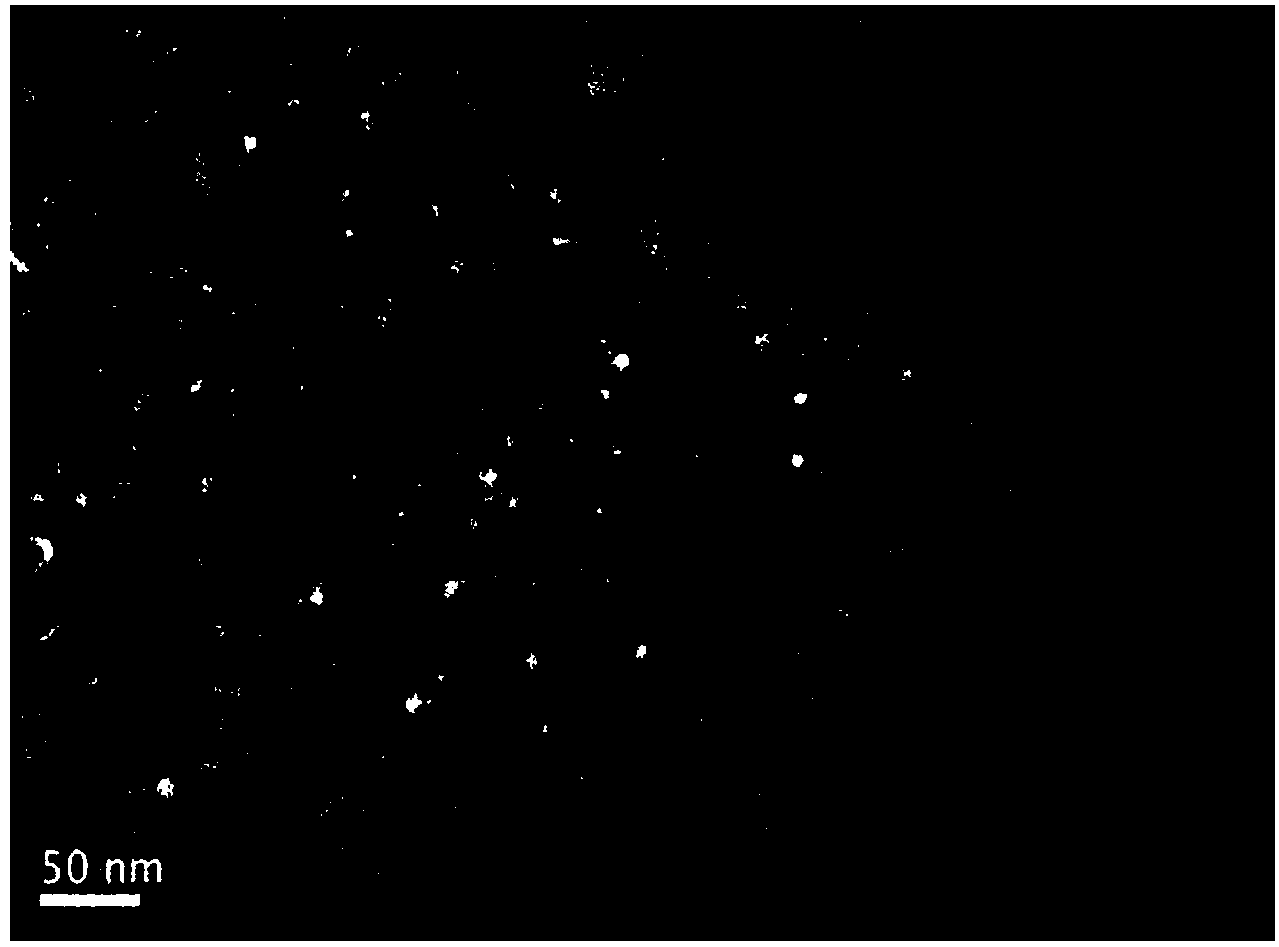

[0037] Characterize the product obtained in this embodiment: the transmission electron microscope (TEM) used for the characterization is the transmission electron microscope of the JEOL 2010 model of JEOL Corporation; the X-ray diffractometer is the X-ray of ...

Embodiment 2)

[0043] This embodiment prepares TiO 2 / g -C 3 N 4 The method all the other of composite visible photocatalyst is identical with embodiment 1, and difference is: step 1. in Ti(OBu) 4 The addition amount of the solution is 5mL, the temperature of ethanol is 25°C, and the temperature of the water bath is 85°C.

[0044] Detected by X-ray diffractometer, the product of the present embodiment is g-C 3 N 4 , Anatase TiO 2 and rutile TiO 2 The mixture of crystals shows that this embodiment has successfully produced TiO 2 / g -C 3 N 4 Composite visible light catalyst.

[0045] TiO prepared in this embodiment 2 / g -C 3 N 4 The TEM spectrum of the composite visible photocatalyst reveals nano-TiO 2 The particles are evenly distributed in the graphite flake g-C 3 N 4 middle.

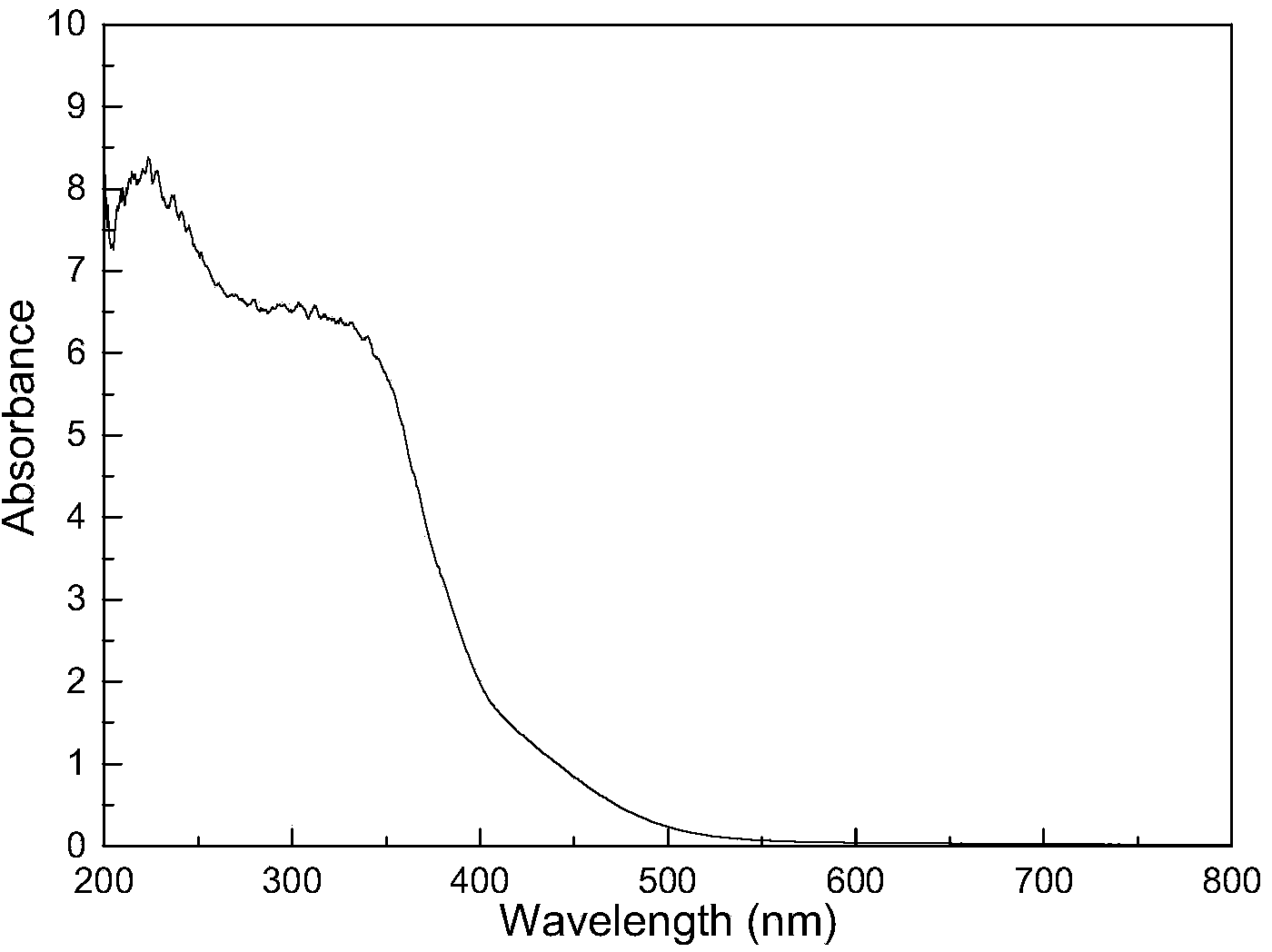

[0046] Detected by the ultraviolet-visible spectrometer, the TiO synthesized in this embodiment 2 / g -C 3 N 4 The visible light absorption region of the composite visible light catalyst is from 390 ...

Embodiment 3)

[0049] This embodiment prepares TiO 2 / g -C 3 N 4 The method all the other of composite visible photocatalyst is identical with embodiment 1, and difference is: step 1. in Ti(OBu) 4 The addition amount of water is 100mL, the dropwise addition amount of water is 1000mL, and the temperature of the water bath is 85°C.

[0050] Detected by X-ray diffractometer, the product of the present embodiment is g-C 3 N 4 , Anatase TiO 2 and rutile TiO 2 The mixture of crystals shows that this embodiment has successfully produced TiO 2 / g -C 3 N 4 Composite visible light catalyst.

[0051] TiO prepared in this embodiment 2 / g -C 3 N 4 The TEM spectrum of the composite visible photocatalyst reveals nano-TiO 2 The particles are evenly distributed in the graphite flake g-C 3 N 4 middle.

[0052] Detected by the ultraviolet-visible spectrometer, the TiO synthesized in this embodiment 2 / g -C 3 N 4 The visible light absorption region of the composite visible light catalyst is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com