Assembling and disassembling method of functional polymer on surface of nano mesoporous carbon dioxide

A nano-mesoporous and silica technology, applied in the field of nano-materials, can solve cumbersome problems and achieve the effect of easy release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Preparation of PEGMA-co-PMAAPHBA:

[0034] (1) Weigh 0.176g of N-(4aminophenyl)-methacrylamide, 0.475g of polyethylene glycol methacrylate and 10mg of initiator, dissolve it in 1.5mL THF, and place the solution in a reaction vessel to freeze After degassing and filling with argon, react in a sealed environment at 65-80°C for 24 hours, and freeze in liquid nitrogen for 2 minutes after polymerization to stop the reaction;

[0035] (2) The reacted solution was precipitated twice with 100 mL of n-hexane and dried.

[0036] (3) 0.4 g of the polymer obtained in step (2) was dissolved in 5 mL of dichloromethane to form solution A, and 0.15 g of 3,4-dihydroxybenzaldehyde was dissolved in 1 mL of methanol solution to form solution B;

[0037] (4) Mix the two solutions of A and B with N 2 After bubbling for 15 minutes, inject solution B into solution A and react for 12 hours. After the reaction, wash with dichloromethane, suction filter and dry to obtain the target substance. ...

Embodiment 2

[0047] 1. Polymer PEGMA-co-PMAAPHBA and nanometer mesoporous silica prepared with reference to Example 1.

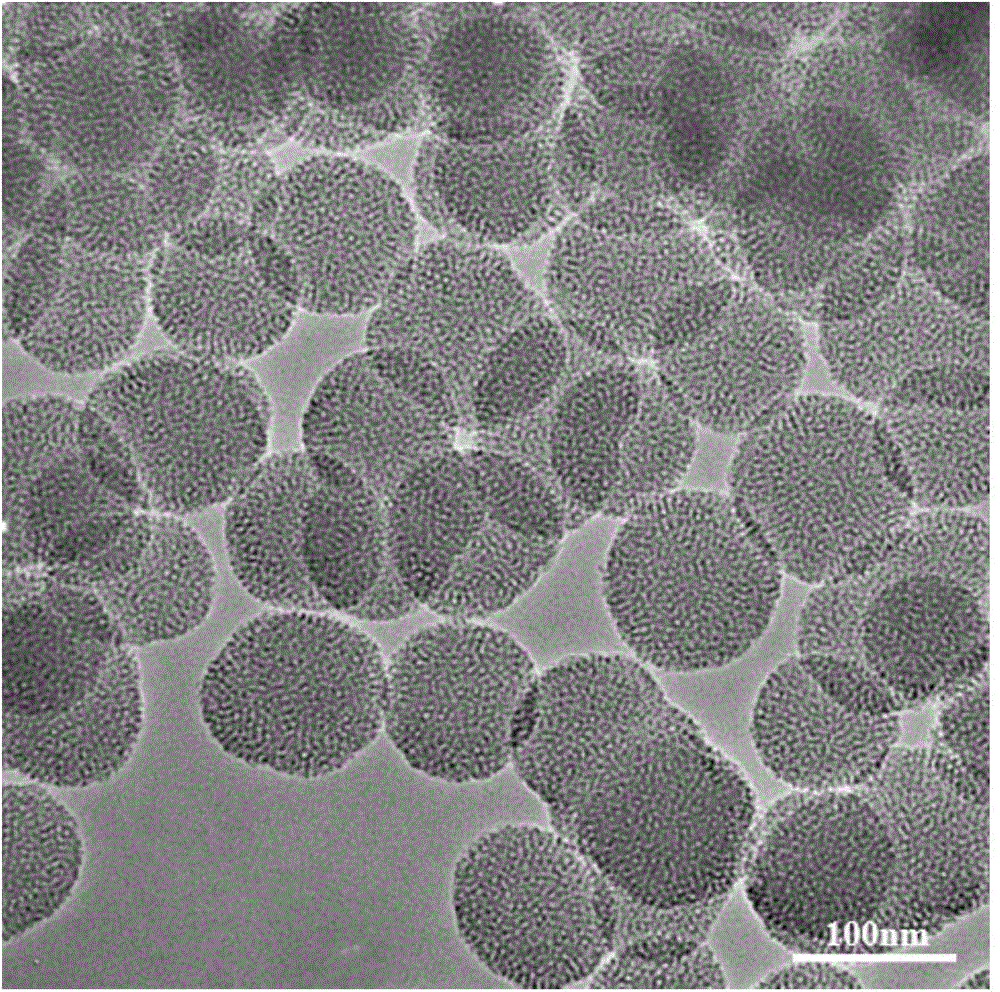

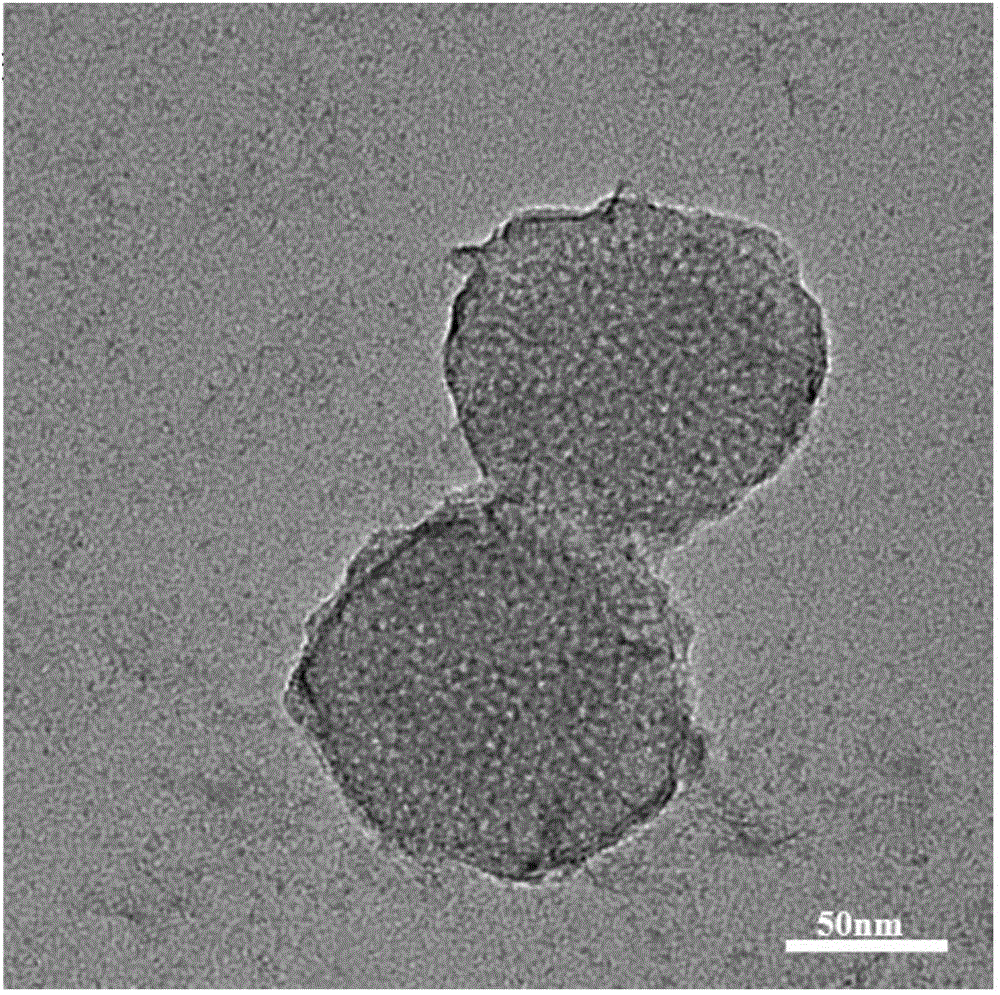

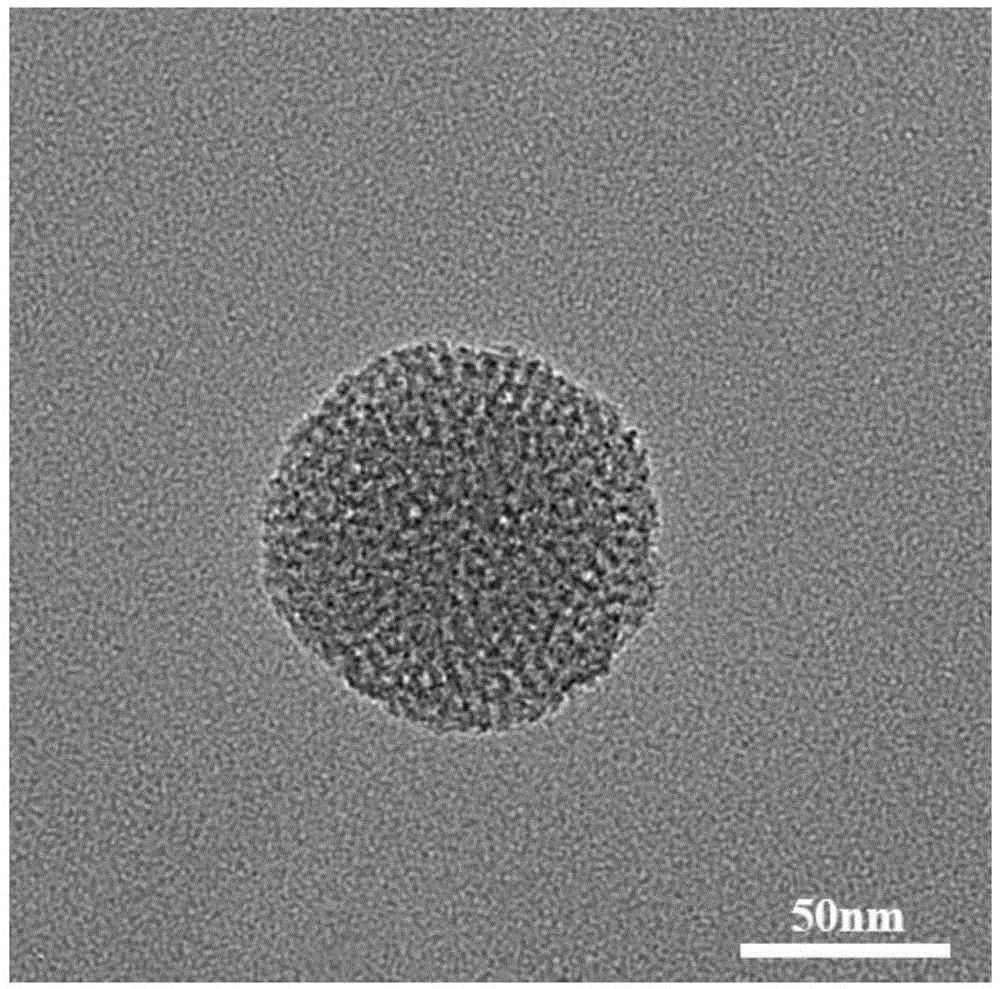

[0048] 2. Prepare 5g / L nanometer mesoporous silica aqueous solution, 5g / L catechol functionalized polymer aqueous solution, 20g / L FeCl 3 Aqueous solution: Add 1.5mL of catechol-functionalized polymer aqueous solution and 0.5mL of metal ion aqueous solution into 2mL of nano-mesoporous silica aqueous solution in sequence, after shaking, the catechol-functionalized polymer coordinates with metal ions, The surface of the nanometer mesoporous silicon dioxide is assembled to obtain an aqueous solution of nanometer mesoporous silicon dioxide coated with a catechol functionalized polymer.

[0049] 3. Centrifuge the nano-mesoporous silica aqueous solution coated with catechol-functionalized polymer in 2, and redisperse the obtained nano-mesoporous silica coated with catechol-functionalized polymer in In water, add acetic acid solution to 1 mL of nano-mesoporous silica solution c...

Embodiment 3

[0051] 1. Polymer PEGMA-co-PMAAPHBA and mesoporous silica prepared with reference to Example 1.

[0052] 2. Prepare 5g / L nanometer mesoporous silica aqueous solution, 5g / L catechol functionalized polymer aqueous solution, 20g / L FeCl 3 Aqueous solution: Add 1.5mL of catechol-functionalized polymer aqueous solution and 0.4mL of metal ion aqueous solution to 1.5mL of nano-mesoporous silica aqueous solution in turn, after shaking, the catechol-functionalized polymer coordinates with metal ions, The assembly is realized on the surface of the nanometer mesoporous silicon dioxide, and an aqueous solution of nanometer mesoporous silicon dioxide coated with a catechol functionalized polymer is obtained.

[0053] 3. Centrifuge the nano-mesoporous silica aqueous solution coated with catechol-functionalized polymer in 2, and redisperse the obtained nano-mesoporous silica coated with catechol-functionalized polymer in In water, add acetic acid solution to 1 mL of nano-mesoporous silica so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com