Seamless steel tube for rare-earth-containing L625Q pipeline and production method of seamless steel tube

A technology for seamless steel pipes and production methods, which is applied in the fields of ferrous metal smelting and metal pressure processing, can solve problems such as unrecorded and unpublished reports, and achieve the effect of low production difficulty and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

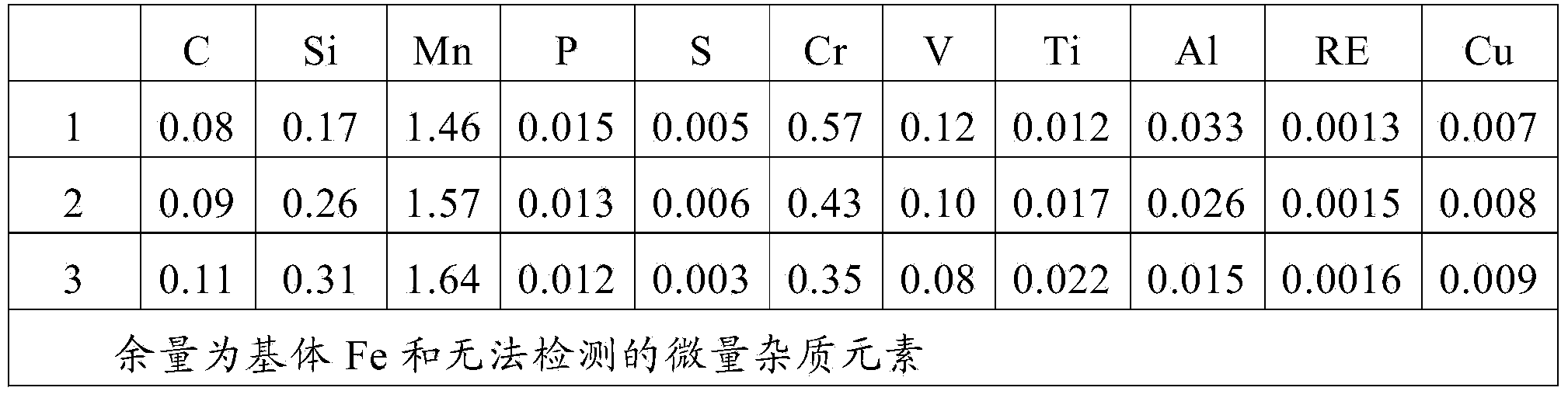

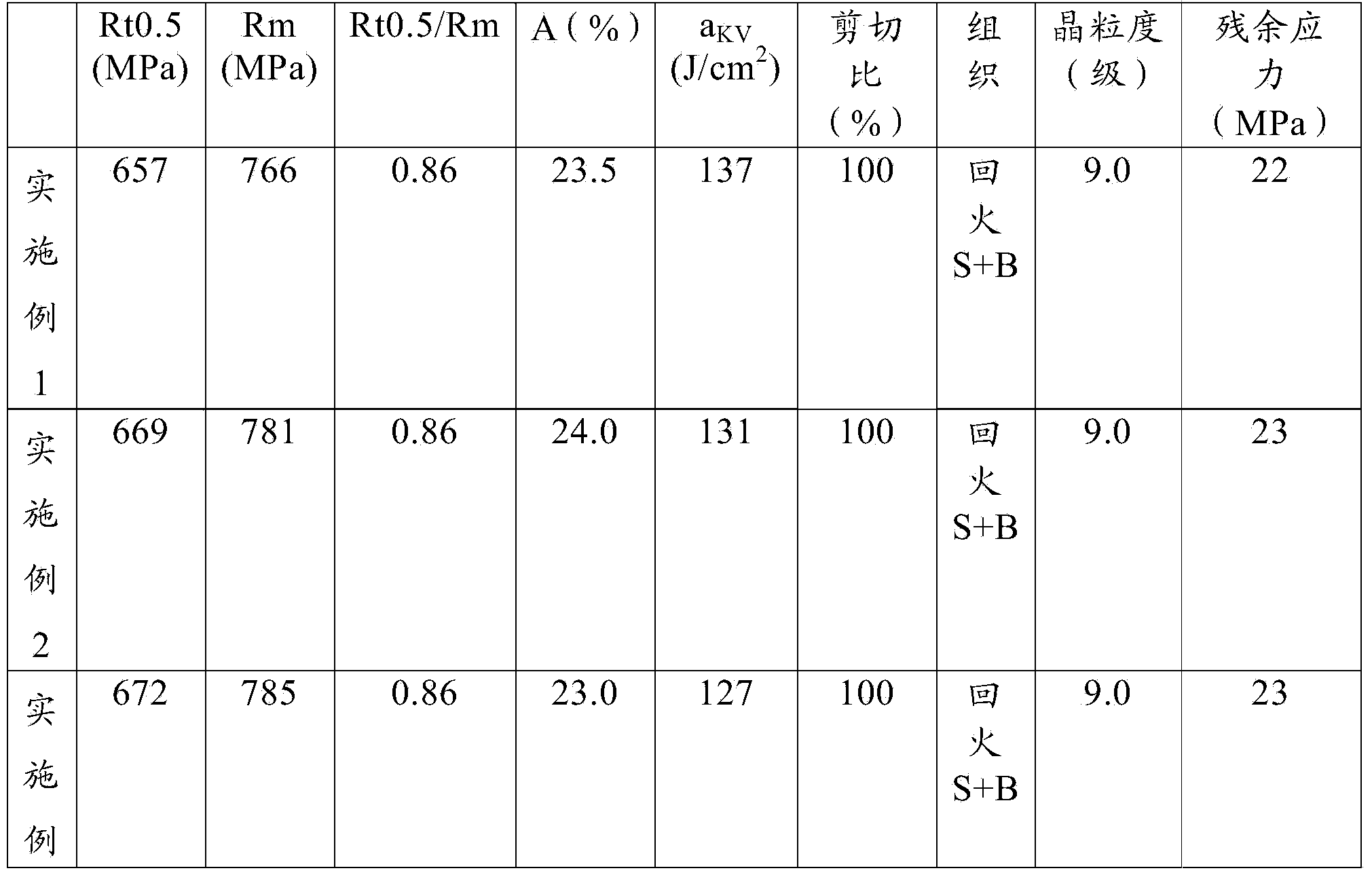

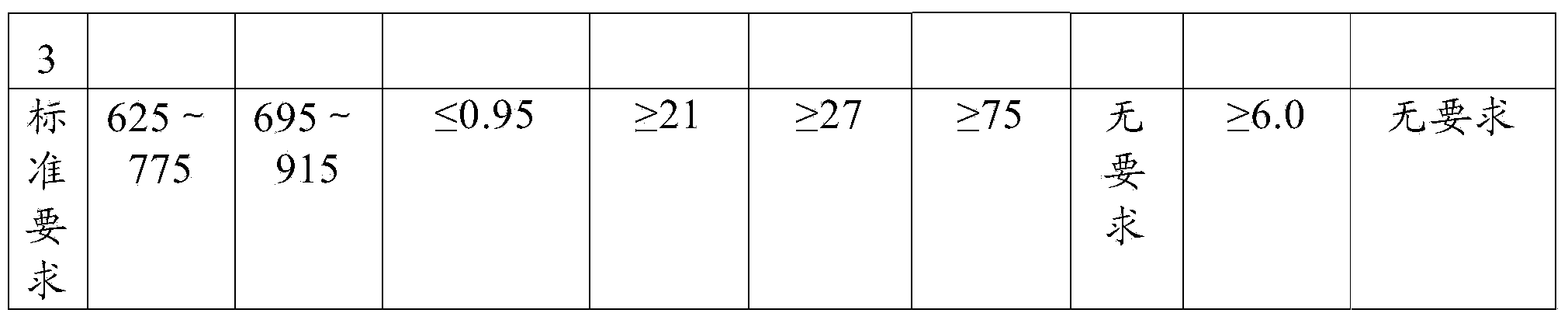

[0033] The above and other technical features and advantages of the present invention will be described in more detail below in conjunction with Embodiment 1 to Embodiment 3.

[0034] The whole smelting process, rolling process and heat treatment process of embodiment 1~embodiment 3 are exactly the same, and the only difference is alloy addition amount and chemical composition, and specific implementation process is as follows:

[0035] Using 0.03 tons of "metal magnesium powder" as a desulfurization pretreatment for 90 tons of blast furnace molten iron, so that the S content in the molten iron is reduced to below (weight percent) 0.010%;

[0036] The 90 tons of pretreated molten iron are mixed into a 100-ton top-bottom combined blowing converter, and then 10 tons of high-quality steel scrap are added, and then the single slag process is used for smelting. The weight percentages of calcium oxide and silicon dioxide in the final slag are as follows: 3.0 control, using silicoman...

PUM

| Property | Measurement | Unit |

|---|---|---|

| residual stress | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com