Preparation method of metal organic framework materials for preferential adsorption of sulfide

A metal organic framework and sulfide technology, which is applied in the field of chemical engineering to achieve the effects of simple process, wide source of raw materials, and improved adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

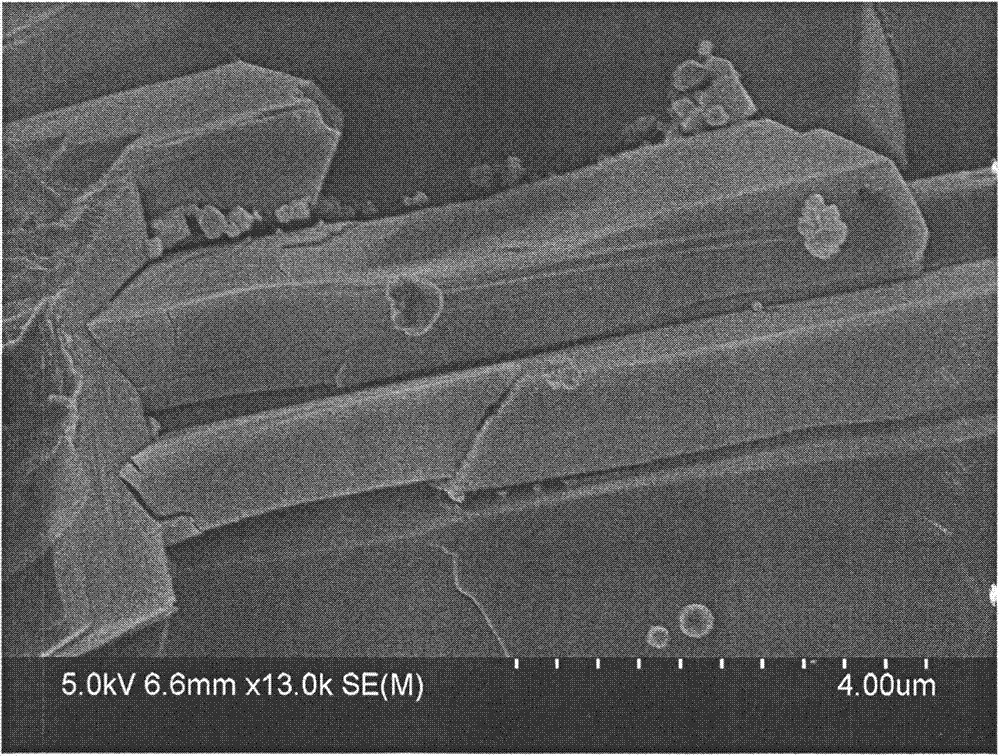

[0028] Preparation of iron-based metal-organic frameworks: Weigh 1.8528g of ferric chloride and 1.328g of terephthalic acid with a fine balance, measure 40ml of N, N-dimethylformamide in a graduated cylinder, pour them into a beaker and mix, wait until After they are all dissolved, the solution is all poured into a hydrothermal reaction kettle with a polytetrafluoroethylene inner wall. Heated in a vacuum oven at 150°C for 10 hours, then vacuum-filtered with a funnel, and vacuum-dried the obtained filtrate at 85°C for more than 5 hours. The obtained yellow crystals were iron-based metal-organic frameworks. The substance is in the shape of a rectangular block with basically the same shape and uniform size. Its microstructure can be seen in figure 1 .

[0029] Implementation effect: Using simulated gasoline (n-heptane, thiophene) as the separation object, the initial sulfur content is 310ug / g, and the operating temperature is 25°C, the adsorption capacity of the prepared iron-ba...

Embodiment 2

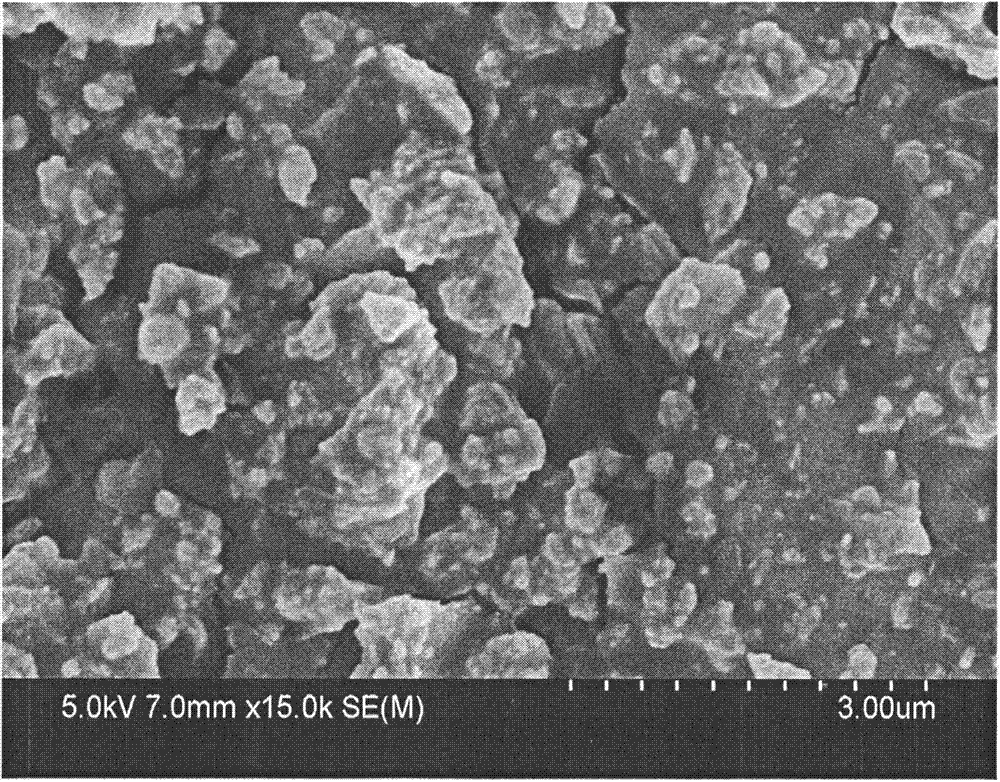

[0031] Preparation of zinc-based metal-organic framework: Weigh 0.334g terephthalic acid and 1.2g zinc nitrate with a fine balance, measure 40ml of N,N-dimethylformamide with a graduated cylinder, pour it into a beaker and stir it with a rotor to make it Dissolves quickly. Then measure 2.2ml of triethylamine, drop it slowly into the beaker drop by drop with a rubber dropper, and keep stirring at the same time, then use a rubber dropper to take 3 to 4 drops of 30% hydrogen peroxide, drop Stir in a beaker to obtain a white precipitate. After vacuum filtration with a funnel, it was washed with N,N-dimethylformamide, and finally the white precipitate was put into a crucible and dried in a vacuum oven at 85°C for about 8 hours. The zinc-based metal-organic framework was prepared, and its microstructure can be seen in figure 2 .

[0032] Implementation effect: Using simulated gasoline (n-heptane, thiophene) as the separation object, the initial sulfur content is 310ug / g, and the...

Embodiment 3

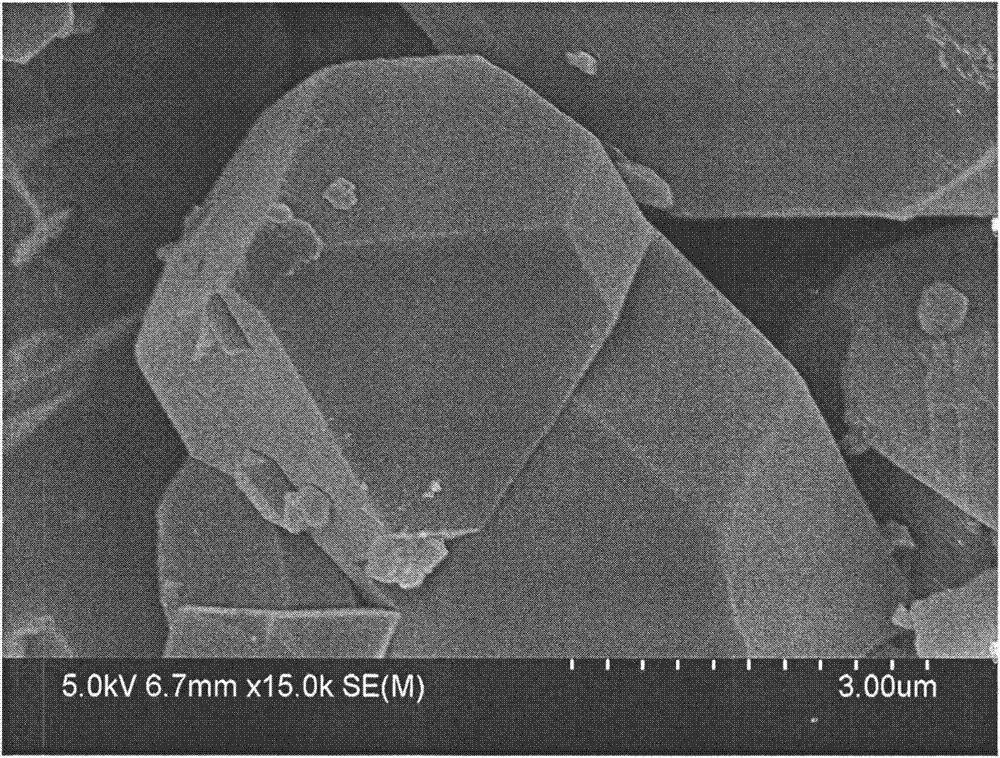

[0034] Preparation of copper-based metal-organic framework: Weigh 3g of tribenzoic acid and 6g of copper nitrate trihydrate with a fine balance, measure 30ml of N,N-dimethylformamide, 30ml of ethanol, and 30ml of water with a graduated cylinder, Then pour it into a beaker, stir it magnetically for 10 minutes to dissolve it completely, then pour the above solution into a conical flask, place it in a drying oven with an asbestos net, and heat it at 100°C for 8 hours, the color of the solution gradually changes from blue to blue. Turn into blue-green, and then turn from blue-green to dark green. At this time, a layer of blue crystals is attached to the bottom of the Erlenmeyer flask, and the blue crystals are vacuum-filtered with a funnel. Pour the obtained blue crystals into a crucible, and dry them under vacuum at 85°C for 10 hours. The obtained crystals are copper-based metal-organic frameworks. The synthesized samples have an octahedral structure, complete crystal structure, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com