A kind of synthetic method of aluminum-containing polycarbosilane

A technology of polycarbosilane and a synthesis method, which is applied to the synthesis field of aluminum-containing polycarbosilane, can solve the problems of inability to perform according to the set metering, unfavorable fiber properties, unfavorable non-melting and the like, and is suitable for large-scale production and technological operation. Simple, highly reactive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

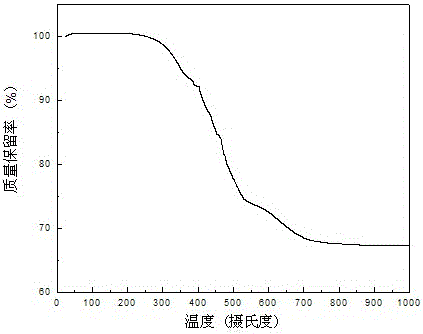

[0033] (1) Put 100 g polycarbosilane in a flask, vacuumize the reaction system, replace the gas in the reaction system with nitrogen to normal pressure, repeat 3 times, add 200 mL xylene to dissolve, and obtain component a; (2 ) Under the protection of a nitrogen atmosphere, add 30 mL of a commercially available heptane solution dissolved in 0.9 mol / L dimethylaluminum chloride to component a obtained in step (1) at room temperature, stir, and heat up to 145 °C, The reaction time is 8 h to obtain component b; (3) Program the temperature of component b obtained in step (2) to 420 °C, keep it warm for 2 h, 350 °C, -0.1 MPa, distill under reduced pressure for 2 h, cool to room temperature, That is, 72.5 g of aluminum-containing polycarbosilane was obtained.

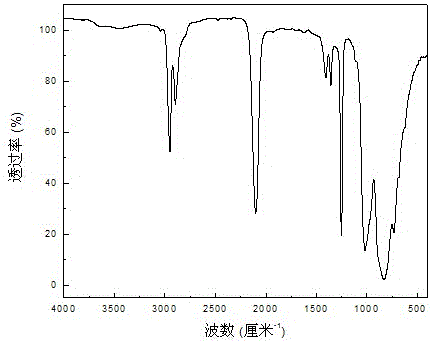

[0034] The yield of aluminum-containing polycarbosilane was 72.5%, and the softening point of the product was 218.8 ℃; the element composition was: Si: 49.01 wt%, C: 42.03 wt%, Al: 1.10 wt%, O: 1.36 wt%, H: 6.50 wt%.

[003...

Embodiment 2

[0039] (1) Put 100 g of polycarbosilane in a flask, vacuumize the reaction system, replace the gas in the reaction system with argon to normal pressure, repeat 3 times, add 250 mL of chloroform to dissolve, and obtain component a; (2) Under the protection of argon atmosphere, add 25 mL of commercially available heptane solution dissolved in 0.9 mol / L methyl ethyl aluminum bromide to the component a obtained in step (1) at room temperature, stir, and raise the temperature program to 145 °C, and the reaction time was 12 h, to obtain component b; (3) program the temperature of component b obtained in step (2) to 400 °C, keep it warm for 3 h, and 360 °C at -0.1 MPa, and distilled under reduced pressure for 1.5 h, After cooling to room temperature, 70.2 g of aluminum-containing polycarbosilane was obtained.

[0040] The yield of aluminum-containing polycarbosilane was 70.2%, and the softening point of the product was 212.3 ℃; the element composition was: Si: 49.66 wt%, C: 41.33 wt%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

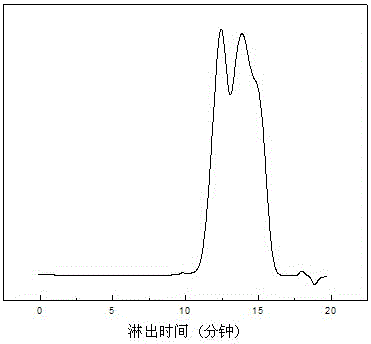

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com