Polyurethane foam and preparation method and application thereof

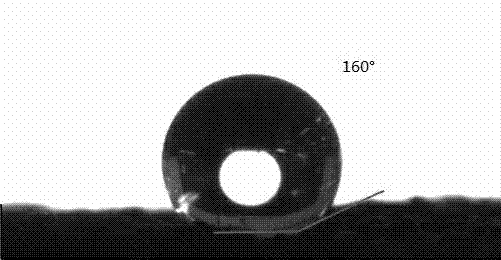

A technology of polyurethane foam and isocyanate, which is applied in chemical instruments and methods, and other chemical processes, can solve the problems of poor hydrophobicity and achieve the effects of high hydrophobicity, large surface roughness, and low surface energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

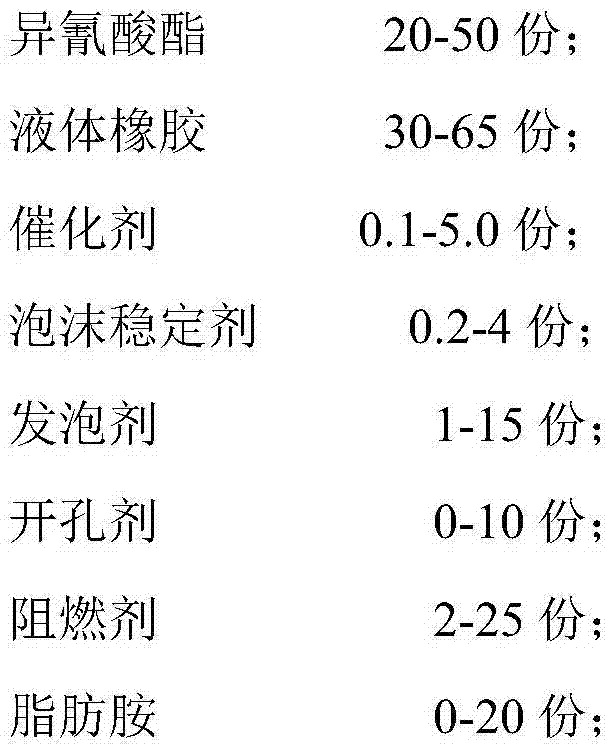

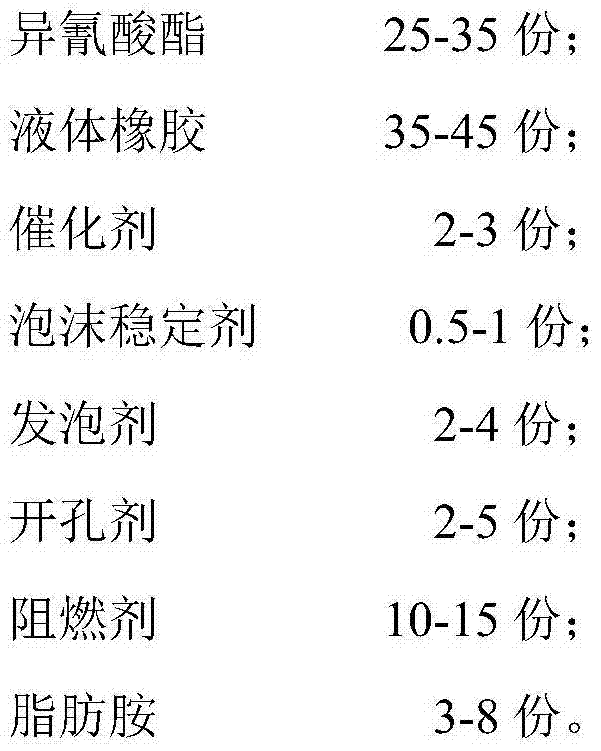

[0065] The superhydrophobic polyurethane foam in this embodiment weighs each raw material component according to the following mass ratio: 25kg isocyanate, 35kg hydroxyl-terminated liquid rubber, 2kg catalyst, 0.5kg foam stabilizer, 2kg blowing agent, 3kg cell opener, 15kg resistance Fuel. Among them, the isocyanate in this embodiment is polymethylene polyphenyl polyisocyanate, the hydroxyl-terminated liquid rubber is grafted with aliphatic amine to epoxidize hydroxyl-terminated polybutadiene, and the catalyst is a combination of tertiary ammonia catalyst and organometallic catalyst. catalyst.

Embodiment 2

[0067] The superhydrophobic polyurethane foam in this embodiment includes the following components: 25kg isocyanate, 40kg hydroxyl-terminated liquid rubber, 2kg catalyst, 0.7kg foam stabilizer, 3kg blowing agent, 3kg cell opener, 10kg flame retardant. The isocyanate in this embodiment is polymethylene polyphenyl polyisocyanate; the carboxyl-terminated liquid rubber is aliphatic amine grafted carboxyl-terminated polybutadiene acrylonitrile; the catalyst is a composite catalyst of a tertiary ammonia catalyst or an organometallic catalyst.

Embodiment 3

[0069] (1) Preparation of aliphatic amine grafted hydroxyl-terminated polybutadiene acrylonitrile

[0070] Add octadecylamine and carboxyl-terminated polybutadiene acrylonitrile (number-average molecular weight 2000, nitrile group content 15%) in the reactor, wherein the nitrile functional group of carboxyl-terminated polybutadiene acrylonitrile and the amino functional group of octadecylamine The molar ratio is 1:1.3. Then add chloroform into the reactor, ultrasonically mix for 15 minutes, react at 65° C. for 4 hours, test the group change by infrared, and the reaction ends when the characteristic peak of the nitrile group disappears. The product obtained from the reaction was submerged in an alcoholic solvent to precipitate naturally, and then distilled under reduced pressure at 95°C and a pressure of -0.95MPa for 3 hours to obtain polybutadiene acrylonitrile grafted with aliphatic amines.

[0071] (2) Preparation of aliphatic amine grafted epoxidized hydroxyl-terminated po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com