Preparation method of half-carbonized iron phthalocyanine wave absorbing agent and wave absorbing agent and application of wave absorbing agent

A technology of semi-carbonized iron phthalocyanine and carbonized iron phthalocyanine, which is applied in chemical instruments and methods, organic chemistry, and other chemical processes, and can solve problems such as high cost, complicated preparation process, and high specific gravity, and achieve low specific gravity and high preparation efficiency. The method is simple and efficient, and the effect of specific gravity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] Preparation of semi-carbonized iron phthalocyanine absorber:

[0039] 1) prepolymerization: with commercially available N-methylpyrrolidone as solvent, commercially available raw material bisphthalonitrile monomer and catalyst ferrocene formaldehyde are dissolved, wherein the bisphthalonitrile monomer in the solution The mass ratio is 94% to 98%, and the mass ratio of ferrocene formaldehyde is 2% to 6%. The mixed solution is heated at 200°C and refluxed for 4 hours, and then the solution is poured into distilled water and stirred, and the stirred Filtrate the precipitate precipitated in the phthalocyanine to obtain the iron phthalocyanine oligomer, wash the iron phthalocyanine oligomer with distilled water for 2 to 3 times, and then dry it;

[0040] 2) Curing: The iron phthalocyanine oligomer obtained in step 1) is cured under the curing program to obtain the iron phthalocyanine polymer. The curing program is: the initial temperature is 250 ° C, and the temperature is r...

Embodiment 1

[0044] 1) according to the mass ratio of two phthalonitrile monomers and ferrocene formaldehyde is 98:2 to take raw materials;

[0045] 2) Solution prepolymerization: Pour bisphthalonitrile monomer and ferrocene formaldehyde into a three-necked flask, add solvent N-methylpyrrolidone, heat, and reflux at 200°C for 4 hours;

[0046] 3) After the prepolymerization is finished, pour the solution into distilled water, stir, filter after precipitation, wash the filtrate, i.e. iron phthalocyanine oligomer, with distilled water for 2 to 3 times, and finally dry it;

[0047] 4) The dried sample was cured according to the program of constant temperature of 250°C for 4 hours, then constant temperature of 280°C for 4 hours, and then constant temperature of 300°C for 4 hours to form iron phthalocyanine polymer;

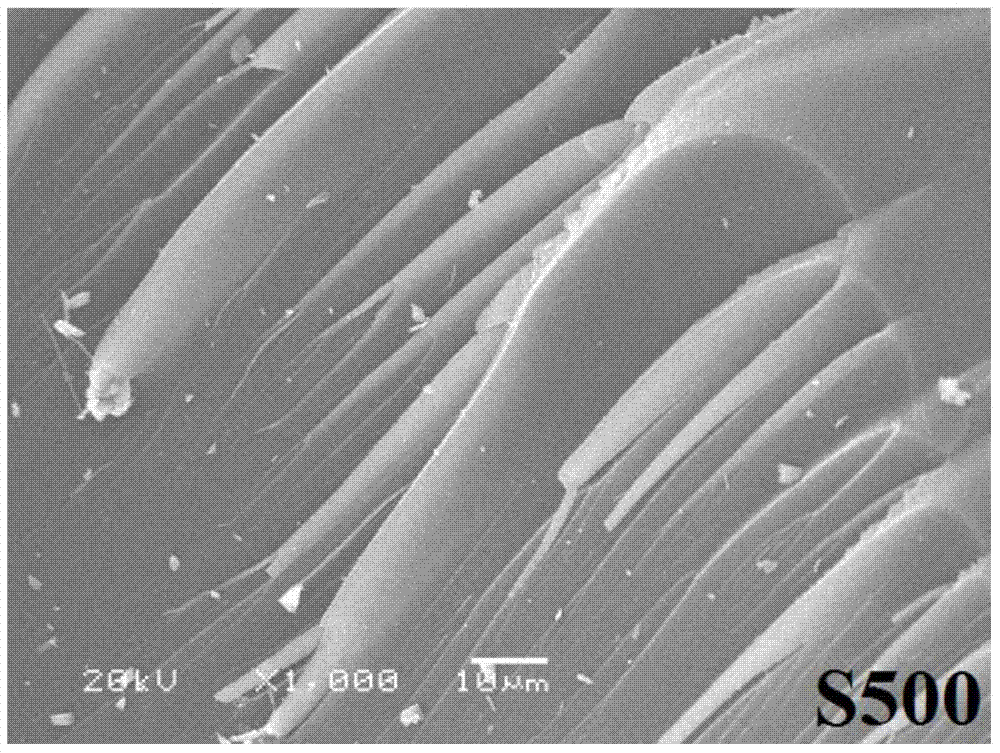

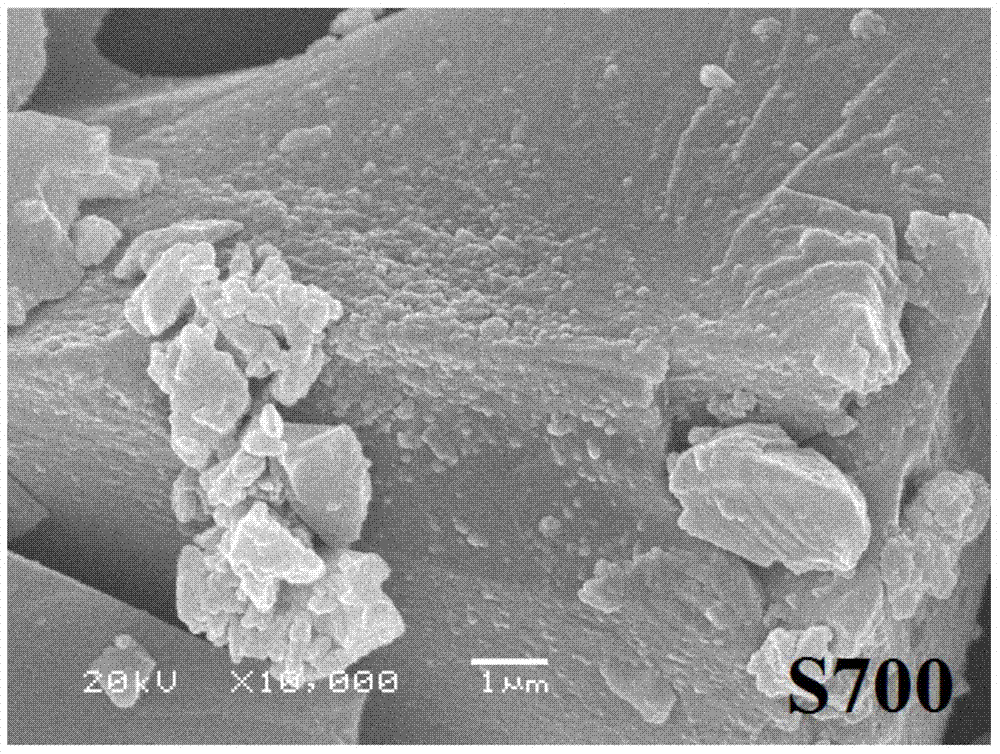

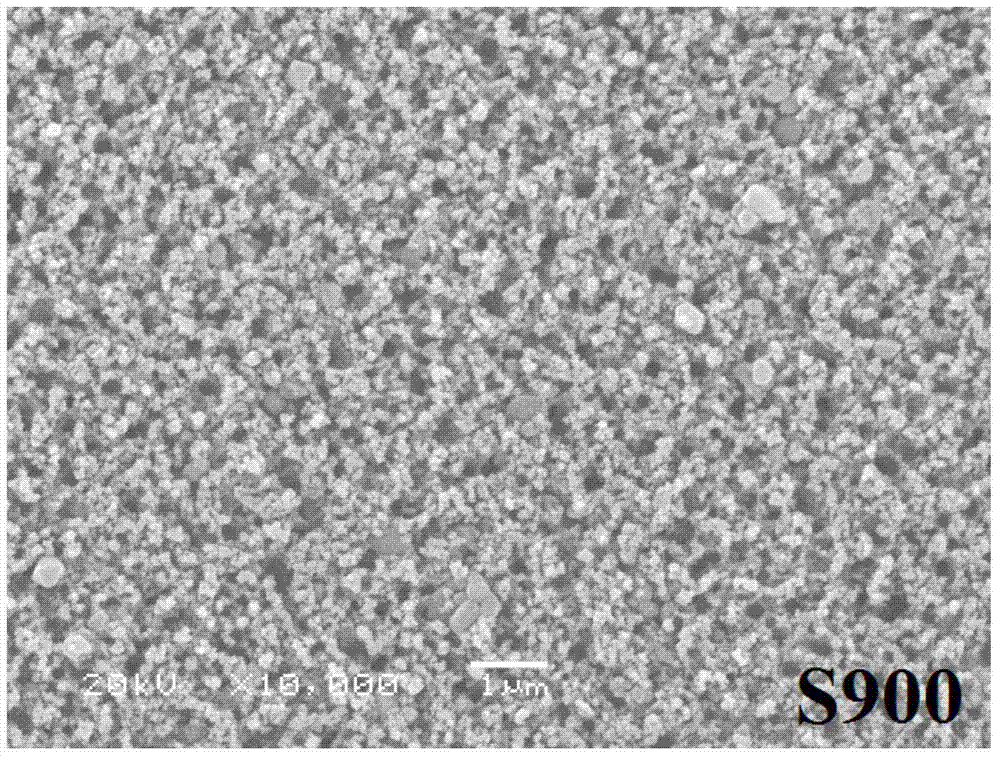

[0048] 5) Under nitrogen atmosphere, divide the iron phthalocyanine polymer obtained in step 4) into 3 groups for pyrolysis. The initial temperature of the cracking program is 300...

Embodiment 2

[0051] 1) according to the mass ratio of two phthalonitrile monomers and ferrocene formaldehyde is 98:2 to take raw materials;

[0052] 2) Solution prepolymerization: Pour bisphthalonitrile monomer and ferrocene formaldehyde into a three-necked flask, add solvent N-methylpyrrolidone, heat, and reflux at 200°C for 4 hours;

[0053] 3) After the prepolymerization is finished, pour the solution into distilled water, stir, filter after precipitation, wash the filtrate, i.e. iron phthalocyanine oligomer, with distilled water for 2 to 3 times, and finally dry it;

[0054] 4) The dried sample was cured according to the program of constant temperature of 250°C for 4 hours, then constant temperature of 280°C for 4 hours, and then constant temperature of 300°C for 4 hours to form iron phthalocyanine polymer;

[0055] 5) Under a nitrogen atmosphere, the iron phthalocyanine polymer was pyrolyzed at a high temperature. The pyrolysis program was an initial temperature of 300°C, then raised ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com