Composite microbial inoculant for treating grease wastewater, and application and use method thereof

A compound microbial agent and wastewater technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of not being able to provide strain mixing optimization methods, and not being able to clarify the role, etc., to achieve high industrial application value , Improving the efficiency of wastewater treatment and reducing the cost of wastewater treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1: the preparation method of the composite microbial bacterial agent of processing grease waste water

[0018] The preparation method of the compound microbial bacterial agent for treating oily wastewater is as follows: respectively take Pseudomonas cepacia, Micrococcus, Bacillus licheniformis, Bacillus amyloliquefaciens, Penicillium expanses and Yarrowia lipolytica to inoculate the actual oily wastewater after sterilization. cultured in an environment of 180rpm and 30°C, and tested the OD of the bacterial solution every 3 hours 600 , to each strain OD 600 Both are 0.30±0.05. Mix 1mL of Pseudomonas cepacia, 1mL of Micrococcus, 2mL of Bacillus licheniformis, 2mL of Bacillus amyloliquefaciens, 2mL of Penicillium dilatans and 2mL of Yarrowia lipolytica , forming a composite microbial agent.

Embodiment 2

[0019] Embodiment 2: the preparation method of the activator that strengthens grease degradation ability

[0020] The preparation method of the compound microbial bacterial agent for treating oily wastewater is as follows: respectively take Pseudomonas cepacia, Micrococcus, Bacillus licheniformis, Bacillus amyloliquefaciens, Penicillium expanses and Yarrowia lipolytica to inoculate the actual oily wastewater after sterilization. cultured in an environment of 180rpm and 30°C, and tested the OD of the bacterial solution every 3 hours 600 , to each strain OD 600 Both are 0.30±0.05. Mix 3 mL of Pseudomonas cepacia, 3 mL of Micrococcus, 1 mL of Bacillus licheniformis, 1 mL of Bacillus amyloliquefaciens, 1 mL of Penicillium dilatans and 1 mL of Yarrowia lipolytica , forming a composite microbial agent.

Embodiment 3

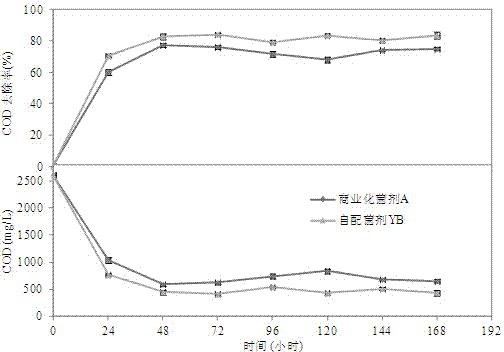

[0021] Embodiment 3: The experiment of adding the compound microbial bacterial agent to the oily waste water grease trap

[0022] A grease trap for treating oily wastewater with an effective volume of 1.5m 3 . According to the dosage of 0.01% of the wastewater volume, take 150mL of oily wastewater, inoculate the compound microbial agent after sterilization, place it in an environment of 180rpm and 30°C for 72 hours, and then add the oily wastewater containing the compound microbial agent to the oil separator In the pool, after that, add once every 8 days, the dosage is the same as above.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com