High-sensitivity electrode type uric acid test paper and manufacturing method thereof

A high-sensitivity, electrode-type technology, applied to the electrochemical variables of materials, material analysis through electromagnetic means, and measurement devices, can solve problems such as difficult control consistency, inaccurate test results, and gaps in stability distances, and achieve High sensitivity, high sensitivity, and the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

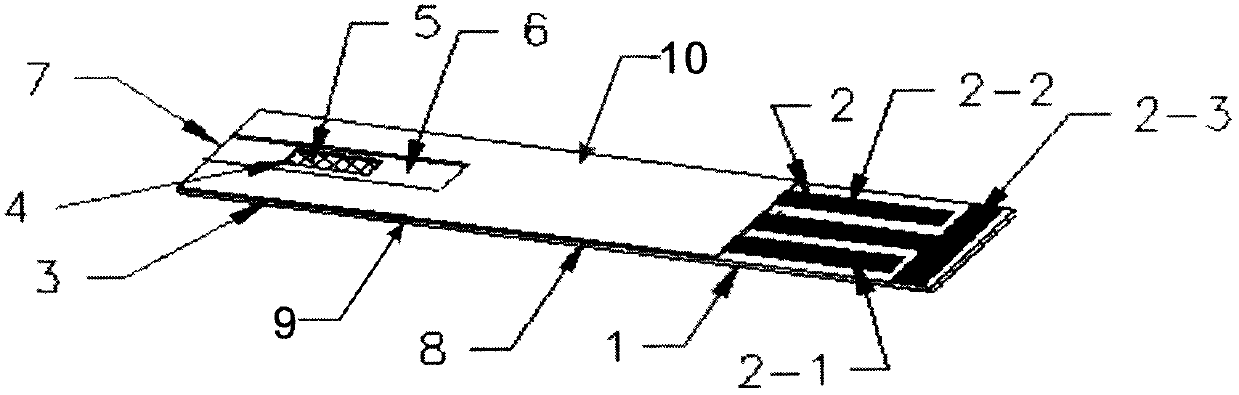

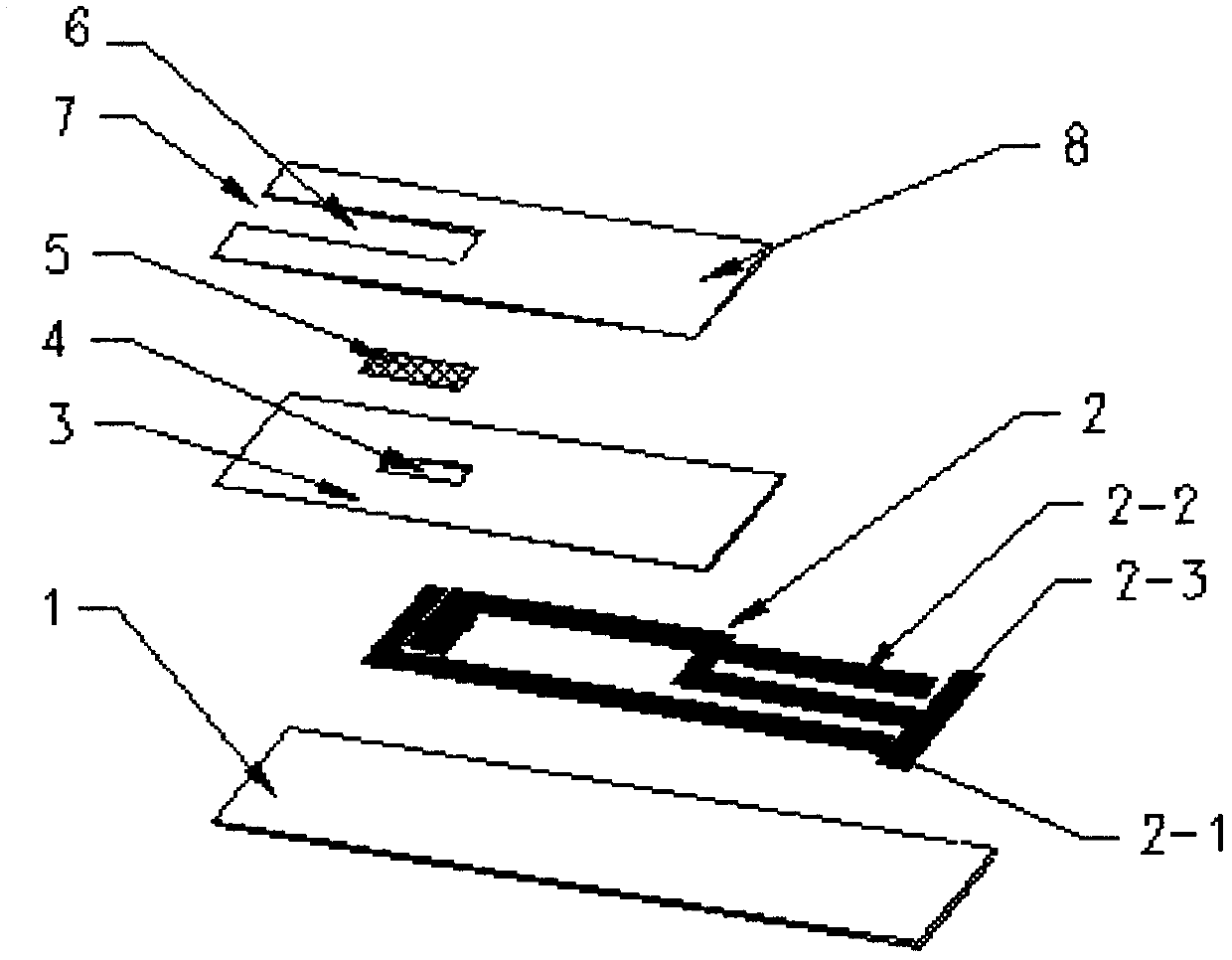

[0050] This embodiment provides a preparation example of an electrode-type uric acid test paper, thereby illustrating the electrochemical biosensor and the preparation method of the present invention.

[0051]First, the working electrode, reference electrode and short-circuit electrode were made on a 0.25mm thick PET plastic substrate by screen printing technology, and the working electrode, reference electrode and short-circuit electrode were made of conductive carbon ink purchased by Acheson Company. Spread the conductive ink on the PET plastic substrate by screen printing to spread a uniformly dispersed ink thin layer, and put it in an oven at 80°C to dry for 60 minutes.

[0052] Secondly, screen printing technology is used to print insulating varnish on the substrate of the printed electrode system as an electrical insulation isolation layer, and the insulating varnish is purchased by Acheson Company. Spread the insulating varnish on the PET plastic substrate by screen pri...

Embodiment 2

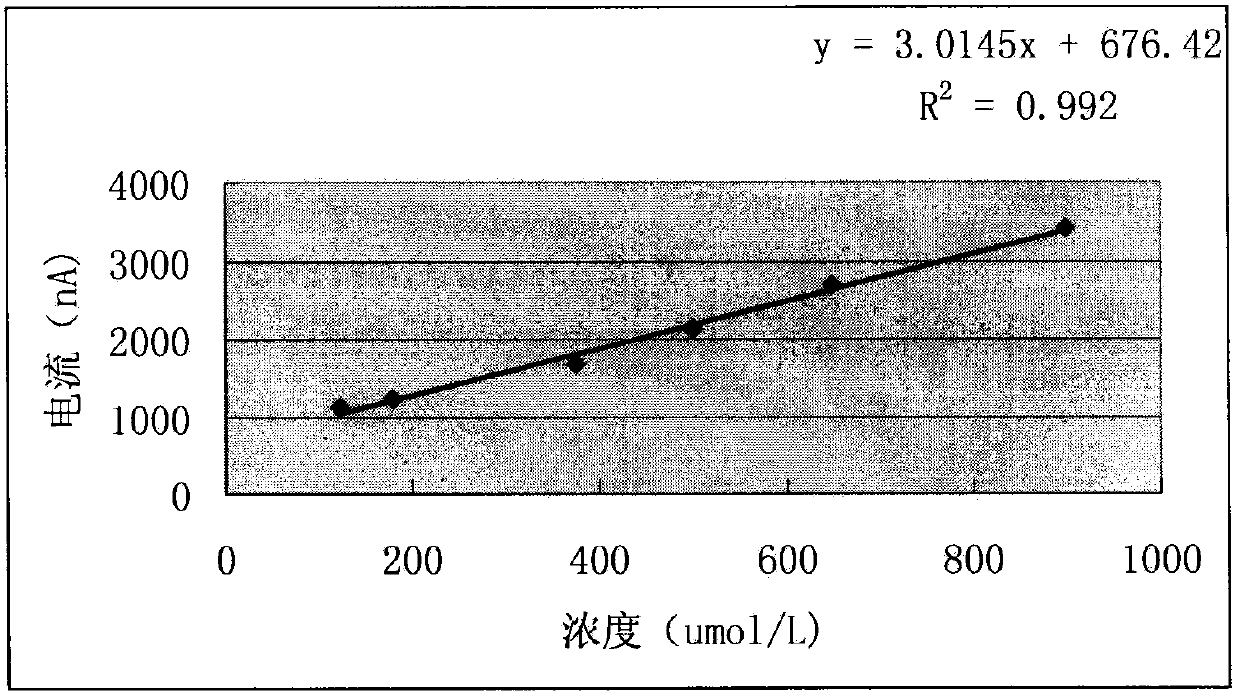

[0061] This example illustrates the linear relationship between uric acid concentration and current, and the method for constructing a calibration curve using the electrode-type uric acid test paper prepared in Example 1.

[0062] Collect fresh venous blood, adjust the hematocrit ratio to 40%, and prepare blood samples with uric acid concentrations of 180 μmol / L, 375 μmol / L, 500 μmol / L, 650 μmol / L, and 900 μmol / L. Place the electrode-type uric acid test paper prepared in Example 1 in a matching tester and apply a working voltage of 300mV across the working electrode and the reference electrode; take blood and add it to the sampling port, and the blood will automatically draw about 2 μL of sample through the siphon sample guide tank , enter the reaction zone and react with the reagents in the enzyme reaction membrane to form a current, and the current corresponding to the concentration of uric acid can be quickly detected on the electrochemical biosensor detection system. The li...

Embodiment 3

[0067] This embodiment illustrates with the electrode type uric acid test paper that embodiment 1 is made and the supporting tester that obtains after inputting the linear curve of embodiment 2 method calibration, and the electrode type uric acid test paper that is made with comparative example 1 and has input comparative example 2 The precision of the blood sample is tested by the supporting tester of the linear curve obtained after the calibration of the method.

[0068] Collect fresh venous blood, adjust the hematocrit ratio to 40%, and prepare blood samples with uric acid concentrations of 275 μmol / L, 450 μmol / L, and 750 μmol / L, respectively. Place the electrode-type uric acid test paper prepared in Example 1 in a matching tester and apply a working voltage of 300mV across the working electrode and the reference electrode; take blood and add it to the sampling port, and the blood will automatically draw about 2 μL of sample through the siphon sample guide tank , enter the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com