Cucumber beverage and production method thereof

A technology for cucumber juice and cucumber is applied in the field of deep food processing to achieve the effects of reducing cooking taste, avoiding adverse effects and prolonging storage period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1, preparation cucumber juice beverage

[0027] (1) Choose fresh cucumbers, and control the mechanical damage area of cucumbers greater than 2% to less than 1%;

[0028] (2) Cleaning: Use an automatic cleaning machine to clean the above-mentioned cucumbers for three times to remove dust, microorganisms and other impurities on the surface of the cucumbers.

[0029] (3) Slicing: Slice the washed cucumber with a slicer, with a thickness of 1mm;

[0030] (4) Beating: the cucumber slices are transported to the beater, and water is added according to the mass ratio (1:2.5) for beating;

[0031] (5) Ingredients: add sucrose and Nisin to the cucumber turbid juice, and stir evenly; the amount of sucrose is 1.1% of the mass of cucumber turbid juice; the amount of Nisin is 0.01% of the mass of cucumber turbid juice;

[0032] (6) Degassing: The cucumber juice homogenized in step (5) enters the vacuum degasser for degassing, the degassing pressure is controlled at 15 ...

Embodiment 2

[0039] Embodiment 2, preparation cucumber juice beverage

[0040] The operation steps of (1)-(7) are the same as those in Example 1; the difference is that the conditions of step (8) are as follows: ultra-high pressure sterilization: use water medium for pressure transmission, and use 500MPa ultra-high pressure sterilization at room temperature for 2 minutes .

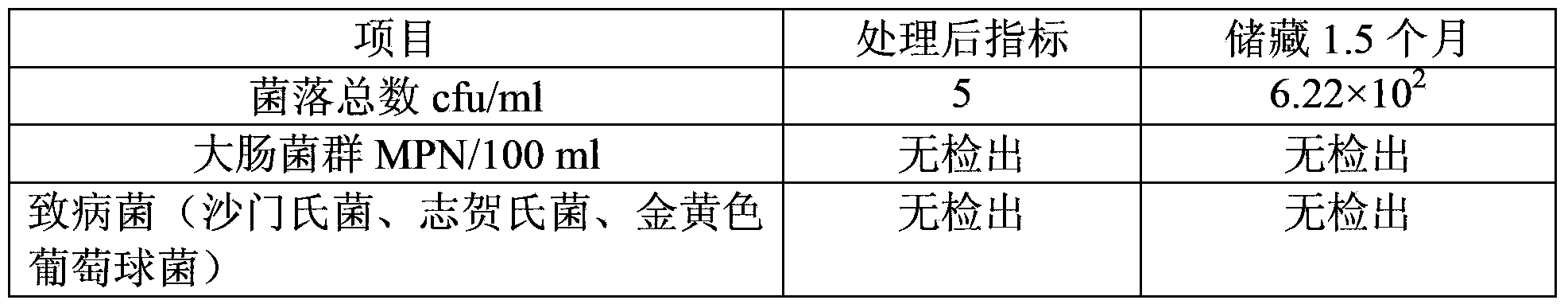

[0041] The cucumber juice drink prepared in this example has good flavor, small nutritional loss, attractive green color, pure taste, and soluble solids of about 3 O For Brix, the pH is 6.6, the microbiological indicators meet the requirements of DB331533-2005, and the shelf life at 4°C reaches 1.5 months. The specific indicators are shown in Table 2.

[0042] Compared with Example 1, although the ultra-high pressure treatment pressure is slightly higher in this embodiment, the treatment time is reduced by 2 minutes, so the equipment loss is reduced and the treatment efficiency is high.

[0043] Table 2 Microbial ind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com