Preparation method of MnOx-CeO2 composite semiconductor catalyst

A compound semiconductor and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve the problems of narrow spectral response of semiconductor materials, limited efficiency of VOCs, high price of precious metals, etc., and achieve improved catalytic purification Efficiency, cheap raw materials, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

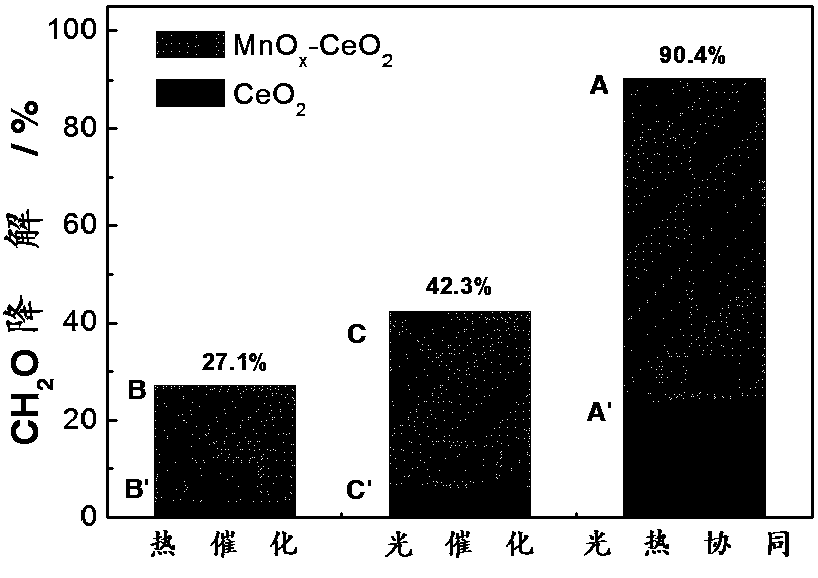

[0033] The present invention relates to a kind of MnO x -CeO 2 Preparation method of composite semiconductor catalyst. The composite semiconductor catalyst can efficiently catalyze and degrade volatile organic pollutants (VOCs) such as formaldehyde, benzene, and acetone under the condition of low-temperature light and heat synergy; In situ regeneration under the action of irradiation.

[0034] The invention relates to a kind of MnO with low-temperature photothermal synergistic catalytic degradation of VOCs and light-assisted self-repair function x -CeO 2 The preparation method of composite semiconductor catalyst comprises the following steps:

[0035] 1) Weigh Ce(Ⅲ,Ⅳ) salt and KMnO 4 , dissolved in deionized water to obtain a uniform mixed solution, and the prepared alkali solution was added to the above mixed solution to obtain a uniform suspension, that is, according to CeO 2 with MnO x The ratio of different substances of the semiconductor is (100-30): (0-70) weigh C...

Embodiment 1

[0049] MnO with low-temperature photothermal synergistic catalytic degradation of VOCs and photo-assisted self-healing function x -CeO 2 The preparation method of composite semiconductor catalyst (Ce / Mn molar ratio 3:1) is as follows:

[0050] (1) Weigh 3mmolCe(NO 3 ) 3 ·6H 2 O and 1 mmol KMnO 4 , added to 40ml of NaOH aqueous solution with a molar concentration of 6M, and magnetically stirred at room temperature to obtain a precipitated nano-seed suspension;

[0051] (2) Move the mixed solution to a 50ml stainless steel reaction kettle with a polytetrafluoroethylene liner, seal it, and conduct a hydrothermal reaction at a temperature of 110°C for 24 hours;

[0052] (3) After the reaction is completed, the reactor is cooled to room temperature, the polytetrafluoroethylene liner is taken out, filtered, washed, and dried at 60°C for 12 hours to obtain MnO x -CeO 2 Composite catalyst (Ce / Mn molar ratio 3:1).

Embodiment 2

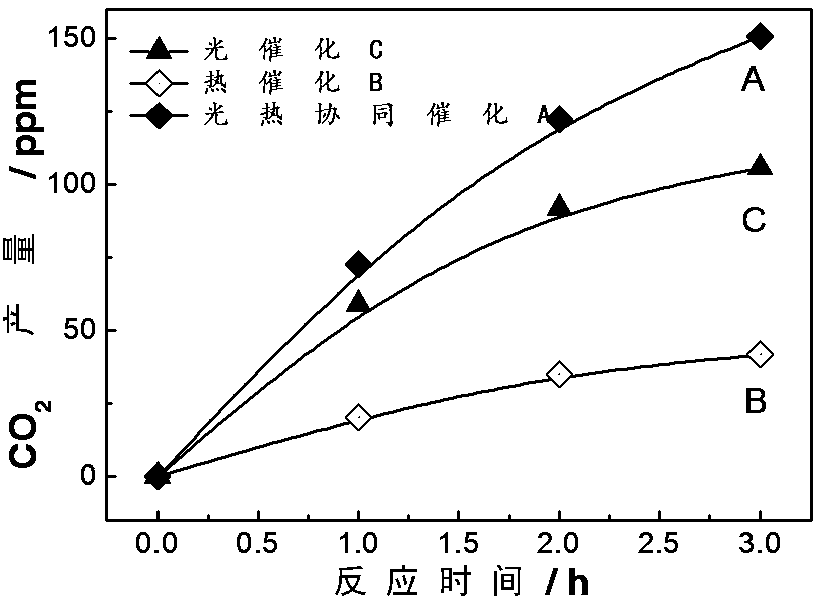

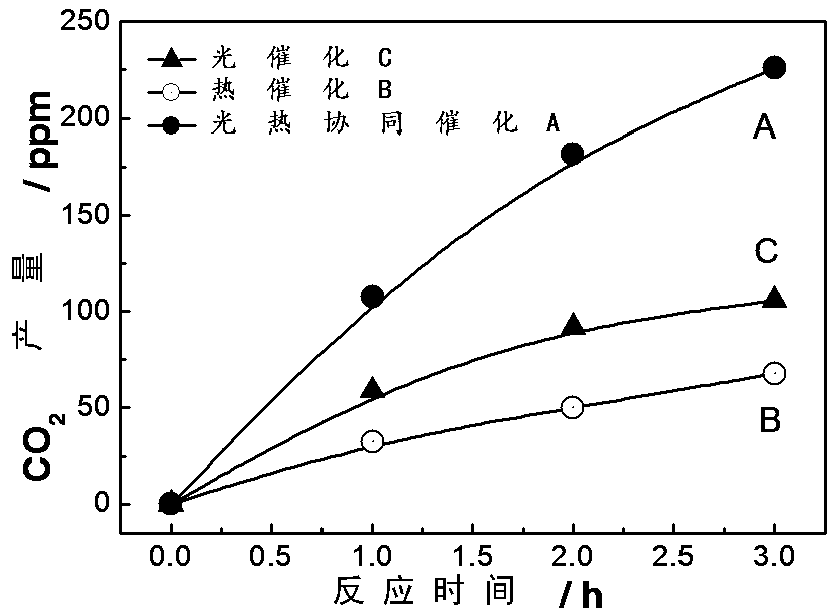

[0054] The MnO that embodiment 1 obtains x -CeO 2 The composite catalyst is used for photothermal synergistic catalytic degradation of 250ppm formaldehyde, and the catalytic reaction temperature is 50°C. The specific implementation steps are as follows:

[0055] (1) take by weighing the MnO that embodiment 1 gains x -CeO 2 0.1g of the composite catalyst was ground and placed at the bottom of the experimental reactor and spread evenly;

[0056] (2) The specific experimental device is described as follows: the experimental reactor is a 650ml cylindrical glass reactor with a jacket that can pass through circulating water, and the top is made of high light-transmitting quartz glass; the upper part is 10cm away from a 500W Xe lamp as a simulated solar light source; The sleeve is connected to the water bath constant temperature tank, which can accurately control the temperature of the catalyst at the bottom of the reactor during the experiment; the reactor is connected to the 789...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com