Anisotropic conductive adhesive for RFID, and its preparation method

A technology of anisotropic conductive adhesive and conductive adhesive, which is applied in the field of preparation of anisotropic conductive adhesive for RFID, can solve problems affecting the performance of anisotropic conductive adhesive, achieve the effect of improving yield and avoiding agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

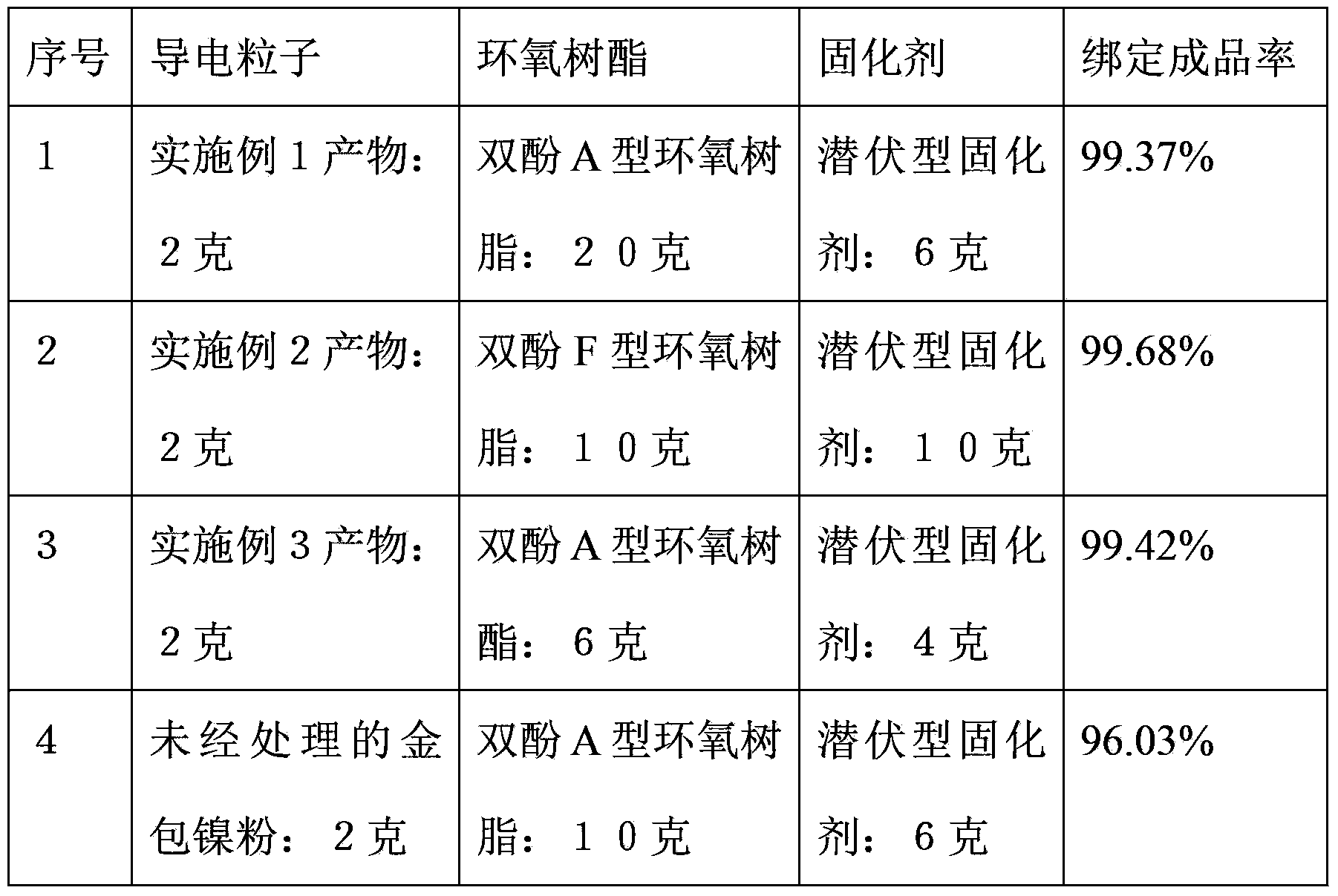

Examples

Embodiment 1

[0034] Gold-coated nickel powder (produced by Shanghai Tianchen Radio Frequency Co., Ltd., particle size 2.5um, gold content 5%) 20g, styrene 2g, polyvinylpyrrolidone 0.6g, volume concentration 50% ethanol aqueous solution 100g, diphenyl peroxide Add 0.2 g of formyl into a 250ml reaction flask, protect it with nitrogen, and ultrasonically disperse and dissolve in a 250W ultrasonic water bath machine, continue ultrasonic dispersion, and polymerize at a water bath temperature of 80°C for 0.5 hours, cool down to 30°C, filter and wash with ethanol, Vacuum drying to obtain the product: gold-coated nickel powder wrapped with polystyrene.

[0035] The obtained product has no obvious agglomeration observed under a 1000-fold microscope, and it can be observed that the surface of the metal micropowder is covered by a nearly transparent polystyrene layer. Analysis of the product by Soxhlet extraction with toluene showed that the mass content of the polymer was 4%.

Embodiment 2

[0037] Gold-coated nickel powder (produced by Shanghai Tesson Radio Frequency Co., Ltd., particle size 2.5um, gold content 10%) 5 grams, styrene 25 grams, polyvinylpyrrolidone 1.25 grams, 99.5% ethanol 250 grams, azobisisobutyronitrile 0.25 gram into a 500ml reaction flask, protected by nitrogen, ultrasonically disperse and dissolve in a 250W ultrasonic water bath machine, continue ultrasonic dispersion, and polymerize at a water bath temperature of 45 degrees for 12 hours, cool down to below 30 degrees, filter and wash with ethanol, and vacuum dry The product obtained: gold-coated nickel powder coated with polystyrene.

[0038] The obtained product has no obvious agglomeration observed under a 1000-fold microscope, and it can be observed that the surface of the metal micropowder is covered by a nearly transparent polystyrene layer. Analysis of the product by Soxhlet extraction with toluene showed that the mass content of the polymer was 50%.

Embodiment 3

[0040] Gold-coated nickel powder (produced by Shanghai Tesson Radio Frequency Co., Ltd., particle size 1um, gold content 20%) 5 grams, styrene 10 grams, polyvinylpyrrolidone 2 grams, 70% ethanol aqueous solution 200 grams, azobisisobutyronitrile 0.5 Add gram into a 500ml reaction flask, protect with nitrogen, ultrasonically disperse and dissolve in a 250W ultrasonic water bath machine, continue ultrasonic dispersion, and polymerize at a water bath temperature of 60°C for 3 hours, cool down to below 30°C, filter and wash with ethanol, and vacuum dry The product obtained: gold-coated nickel powder coated with polystyrene.

[0041] The obtained product has no obvious agglomeration observed under a 1000-fold microscope, and it can be observed that the surface of the metal micropowder is covered by a nearly transparent polystyrene layer. Analysis of the product by Soxhlet extraction with toluene showed that the mass content of the polymer was 30%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com