An ionic liquid-loaded hollow liquid-core microencapsulated cell and its application

A technology of ionic liquid and air liquid, which is applied in the direction of fixing on or in the inorganic carrier, fixing on/in the organic carrier, etc., can solve the problem of high cost of using ionic liquid, reducing the amount of ionic liquid used, and the price of ionic liquid Expensive and other issues, to achieve the effect of improving mechanical strength, improving mass transfer performance, and closely connecting the three-layer structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] A method for preparing ionic liquid-loaded hollow liquid core microencapsulated cells, comprising the following steps:

[0055] (1) Preparation containing 15g L -1 Calcium chloride, 30g·L -1 Acetic acid solution of chitosan, wherein the concentration of calcium chloride is 15g L -1 , the concentration of chitosan is 30g·L -1 , the concentration of acetic acid is 0.175mol L -1 .

[0056] (2) In the acetic acid solution that step (1) makes, add the [BMIm]PF that purity is greater than 99% 6 to a concentration of 90.0g·L -1 , and magnetically stirred it for 2h, and mixed evenly to obtain a mixed solution.

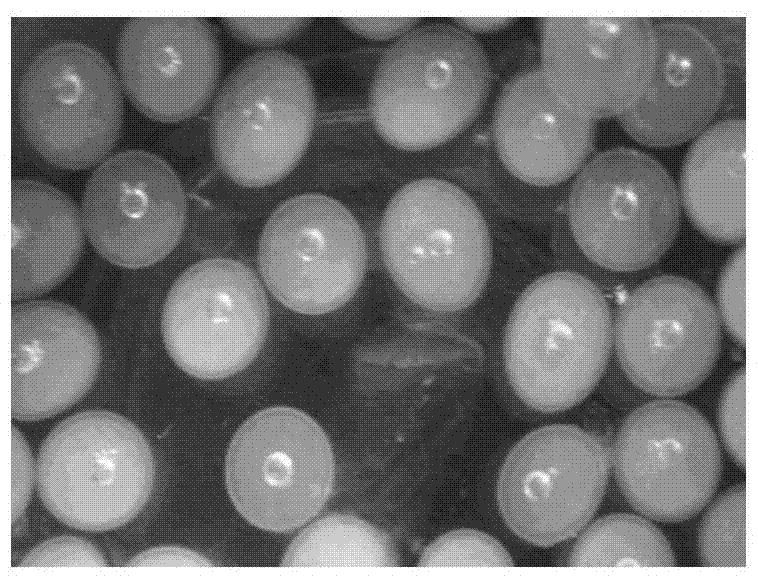

[0057] (3) Pipette 100mL of basic enzyme-producing medium into an Erlenmeyer flask, sterilize, inoculate Penicilliumpurpurogenum Li-3, cultivate at 30°C and 170r / min for 96h, centrifuge (20°C, 8000r / min, 10min), Discard the supernatant; take the bacteria, wash with 0.9% normal saline, centrifuge, weigh the wet weight of the bacteria, resuspend with 0.9% normal sa...

Embodiment 2

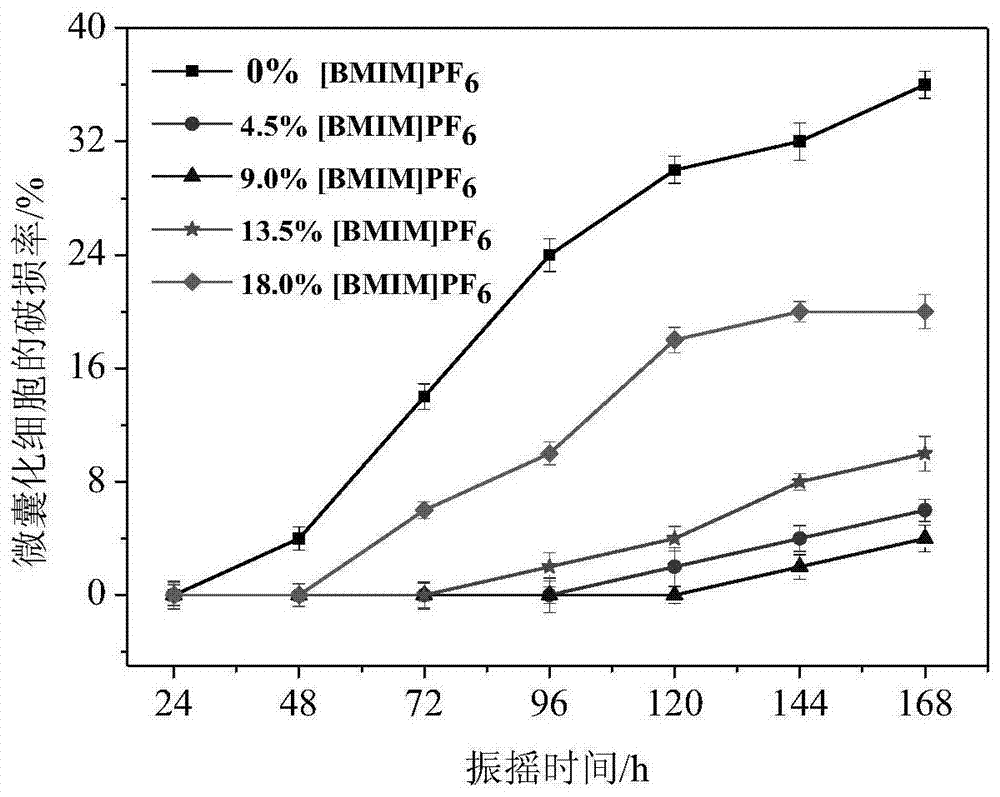

[0064] Load different concentrations of [BMIM]PF with 10g 6 Put the microencapsulated cells into the Erlenmeyer flask containing 100mL of normal saline, place the Erlenmeyer flask on a shaker at 32°C and 150r / min to shake, take samples at different intervals, count the number of complete microcapsules, and calculate Breakage rate of microcapsules. Then, continue to put the intact microcapsules into normal saline for detection, and investigate the loading of different concentrations of [BMIM]PF 6 The mechanical strength of the microencapsulated cells ( figure 2 ).

[0065] from figure 2 It can be seen that as the shaking time increases, the breakage rate of the microcapsules will increase continuously, that is, the mechanical strength will decrease. After shaking for 168h, no load [BMIM]PF 6 The breakage rate of the microcapsules is the highest.

[0066] This is because the capsule membrane of the microcapsule is composed of a three-layer structure of calcium alginate c...

Embodiment 3

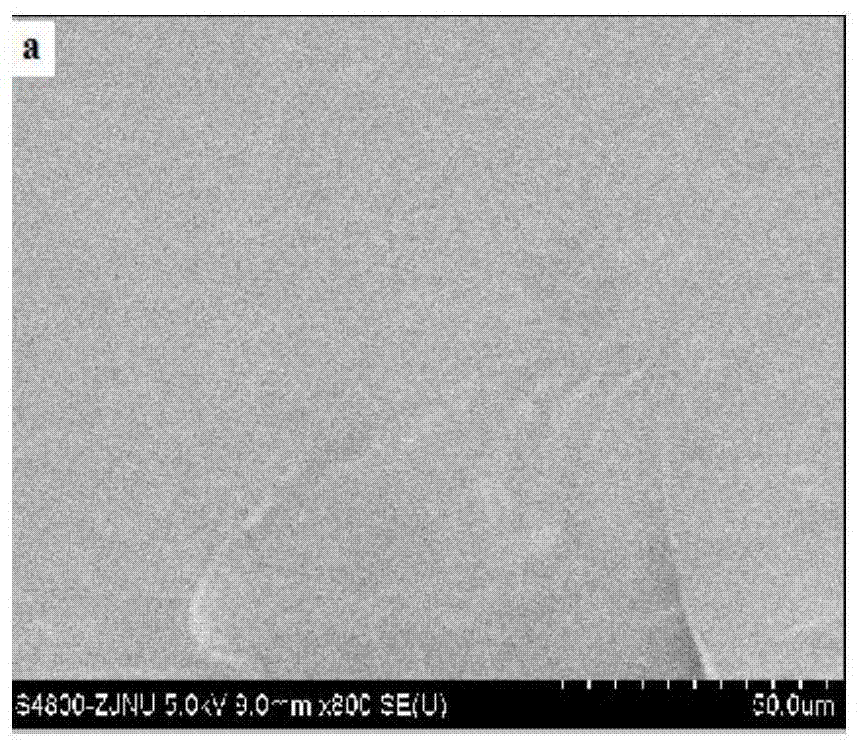

[0070] Will load different concentrations of [BMIm]PF 6 The microencapsulated cells were placed in a vacuum drying oven at 65°C for 24 hours and then analyzed by scanning electron microscopy. 6 The microscopic morphology of the microencapsulated cells was characterized, and the analysis results are shown in Figure 3a , 3b , 3c, 3d, 3e.

[0071] Depend on Figure 3a Visible, unloaded [BMIm]PF 6 The surface of the microencapsulated cells is basically smooth with only few wrinkles, which shows that the components in the capsule of the microencapsulated cells have good compatibility.

[0072] Depend on Figure 3b ([BMIm]PF 6 The concentration is 45.0g·L -1 )with Figure 3c ([BMIm]PF 6 The concentration is 90.0g·L -1 ) can be seen, the load [BMIm]PF 6 The microencapsulated cells have more pores on the capsule, and the surface is basically smooth. When [BMIm]PF 6 The addition amount is 90.0g·L -1 , the pores on the surface of the microencapsulated cells were the most. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com