Method for preparing electronic conductive micro-sphere for producing anisotropic conductive film by simply absorbing metal palladium ions

A technology of anisotropic conductive film and metal palladium, which is applied in the field of preparing conductive microspheres, can solve the problems of inappropriateness and aging resistance, and achieve the effects of simplified adsorption, smooth surface gold layer, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

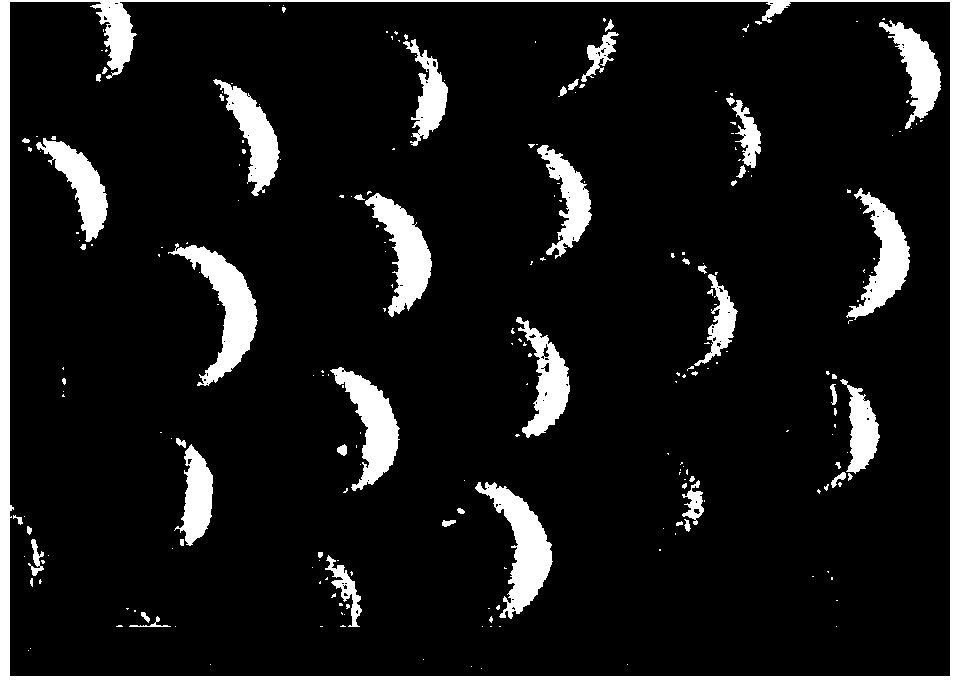

[0042] The invention proposes a method for preparing conductive microspheres, and the conductive microspheres are the conductive microspheres used in the production of anisotropic conductive films.

[0043] The preparation method of the conductive microspheres comprises the steps of:

[0044] Step 1: Add the monomer, dispersant, initiator and solvent into the reaction vessel and mix evenly, under the protection of inert gas, polymerize at a constant temperature of 50-80°C for 2-24h, centrifuge, wash with water, and dry to obtain polymer bulbs, bulbs The particle size is 400nm - 8μm;

[0045] Step 2: disperse the bulbs obtained in step 1 into an aqueous solution containing a surfactant and a dispersant, and stir evenly with ultrasonic waves to prepare a bulb dispersion;

[0046] Step 3: Dissolving the initiator in the oily liquid of cross-linking agent, active monomer and chain transfer agent mixed in mass proportion, adding a certain mass proportion of surfactant, dispersant ...

preparation Embodiment 2

[0074] Take 0.2 g of the polymer seed balls in Preparation Example 1 and disperse them in 100 g of water, add 1 g of SDS and 3 g of PVP, ultrasonically homogenize them, add them into a three-necked flask and stir evenly to obtain a seed ball dispersion.

[0075] Dissolve 3g of AIBN in 30g of TMPTMA, 15g of AAEM, and 5g of mercaptoethanol, then add 120g of water, 6g of ethanol, and 2.0g of SDS, and stir ultrasonically for 30 minutes to obtain an emulsion.

[0076] The emulsion was added to the bulb dispersion for swelling for 24 hours to obtain a swelling solution.

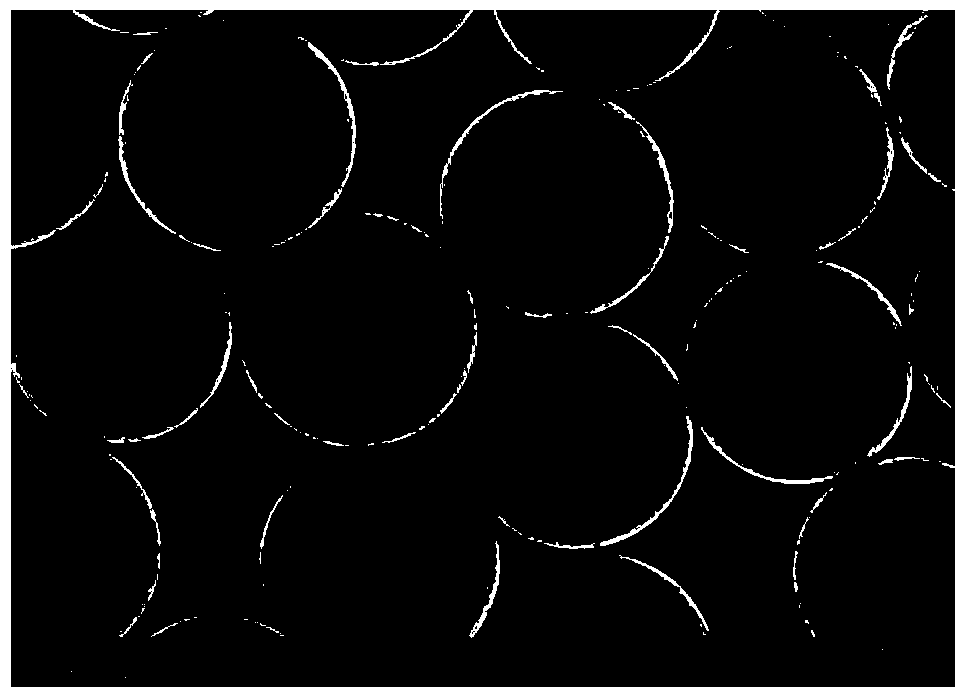

[0077] The swelling solution was placed in a 90°C water bath for constant temperature polymerization for 5 hours, then washed by centrifugation, and dried in vacuum. White monodisperse cross-linked polymer microspheres with a size of about 9.3 μm were obtained.

[0078] Take 1 g of the white monodisperse crosslinked polymer microspheres obtained above and disperse them in 10 mL of a solution with a mass concentrat...

preparation Embodiment 3

[0083] Take 0.2 g of the polymer seed balls in Preparation Example 1 and disperse them in 300 g of water, add 3 g of SDS and 9 g of PVP, ultrasonically homogenize them, add them into a three-necked flask and stir evenly, to obtain a seed ball dispersion.

[0084] Dissolve 3g of AIBN in 30g of EGDMA, 10g of AAEM, 5g of ST, and 5g of mercaptoethanol, then add 600g of water, 20g of ethanol, and 4.5g of SDS, and stir ultrasonically for 30 minutes to obtain an emulsion.

[0085] Add the emulsion into the bulb dispersion and stir evenly for 24 hours to obtain a swelling solution.

[0086] The swelling solution was placed in a 90°C water bath for constant temperature polymerization for 5 hours, then washed by centrifugation, and dried in vacuum. White monodisperse cross-linked polymer microspheres with a size of about 8.3 μm were obtained.

[0087] Take 1 g of the above-mentioned white monodisperse cross-linked polymer microspheres and disperse them in 10 mL of a solution with a mas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com