Steric hindrance amine desulfurizing agent and preparation method thereof

A technology of sterically hindered amines and desulfurizers, applied in separation methods, chemical instruments and methods, preparation of organic compounds, etc., can solve the problems of complex reactions and great differences in reaction rates, and achieve large absorption capacity, low operating costs, Good desulfurization selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A. Put 103.90ml of tert-butylamine with a purity of ≥99.0%, 32.9121g of 1,3-dichloro-2-propanol with a content of 98%, and 100ml of absolute ethanol into the reactor, heat to 130-145°C, and pressurize Respond for 2.0 hours;

[0024] B. Pour out the above reactant after cooling to 70°C, add saturated NaOH solution (10%), neutralize and react under reflux for 0.5 hours, then cool to ≤30°C;

[0025] C, the neutralized solution is extracted with ethyl acetate (3 * 70ml), to obtain the upper layer extract;

[0026] D. Dry the extract in C with anhydrous magnesium sulfate for 2 hours, and filter.

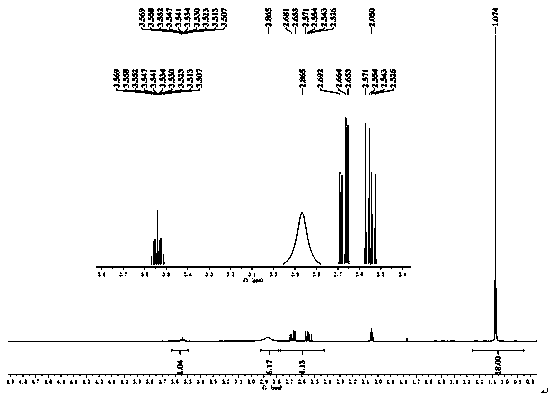

[0027] E. The liquid in D was distilled under reduced pressure and crystallized by cooling to obtain 48.6015 g of the target crystal, which was analyzed as 1,3-di-tert-butylaminoisopropanol by infrared and nuclear magnetic chromatography, with a yield of 96.1%.

Embodiment 2

[0028] Embodiment 2 The process steps of this embodiment are the same as those of Embodiment 1.

[0029] First, put 52..20ml of tert-butylamine with a purity of ≥99.0%, 16.4846g of 1,3-dichloro-2-propanol with a content of 98%, and 50ml of UP-grade pure water into the reactor, and heat it to 130-145°C. Reaction under self-pressure for 2.0 hours, cooled to about 65°C and poured out, then added saturated NaOH solution and refluxed and neutralized at 80°C for 0.5 hours, then cooled to about 25°C, extracted with EA, dried, filtered, and reduced Cooling and crystallization after pressure distillation yielded 24.1796 g of 1,3-di-tert-butylaminoisopropanol with a yield of 95.6%.

Embodiment 3

[0030] Example 3 In this example, distilled water and absolute ethanol were used as the reaction medium. 51.90ml of tert-butylamine, 16.4832g of 1,3-dichloro-2-propanol, 25ml of water, and 25ml of absolute ethanol were mixed and placed in a reaction kettle. The reaction temperature is 130-145°C. After 2.0 hours of self-pressurized reaction, cool down to 65°C together with the reactor and pour it out, then add saturated NaOH solution and reflux at 70°C for 0.5 hours, then lower the temperature to room temperature (about 28°C) , extracted with EA, dried, filtered, and distilled under reduced pressure, then cooled and crystallized to obtain 24.2793 g of 1,3-di-tert-butylaminoisopropanol, with a yield of 96.0%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com