Method for continuous recovery of by-products from glyphosate hydrolysis tail gas

A technology for glyphosate and by-products, which is applied in the field of continuous recovery of by-products from glyphosate hydrolysis tail gas, can solve problems such as inability to separate, affect the quality of methanol, and affect the quality of methyl chloride, so as to achieve reasonable design, improve the quality of by-products, and increase energy The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

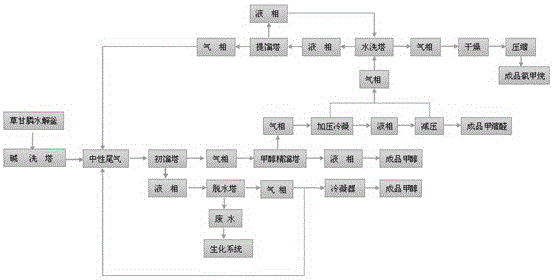

[0025] Such as figure 1 Shown, the method specific steps of glyphosate hydrolysis tail gas continuous recovery by-product are as follows:

[0026] 1) After the glyphosate hydrolysis tail gas is alkali-washed, it is treated in an alkali-washing tower to make the pH of the tail gas reach 7.5;

[0027] 2) The neutral tail gas enters the initial distillation tower for treatment, the temperature at the top of the initial distillation tower is controlled at 60°C, and the temperature at the bottom of the tower is 105°C. The liquid phase obtained at the bottom of the initial distillation tower enters the dehydration tower, and the temperature at the top of the dehydration tower is controlled at 95°C. The temperature at the bottom of the tower is 100°C, the COD of the waste water at the bottom of the dehydration tower is less than 5000mg / L, the gas phase obtained from the top of the initial distillation tower enters the methanol rectification tower for treatment, and the temperature at...

Embodiment 2

[0034] 1) After the glyphosate hydrolysis tail gas is alkali-washed, it is treated in an alkali-washing tower to make the pH of the tail gas reach 8.0;

[0035] 2) The neutral tail gas enters the primary distillation tower for treatment. The temperature at the top of the primary distillation tower is controlled at 62°C, and the temperature at the bottom of the tower is 107°C. The liquid phase obtained at the bottom of the primary distillation tower enters the dehydration tower, and the temperature at the top of the dehydration tower is controlled at 97°C. The bottom temperature of the tower is 102°C, the COD of the waste water at the bottom of the dehydration tower is less than 3000mg / L, and the gas phase obtained from the top of the primary distillation tower enters the methanol rectification tower for treatment.

[0036] 3) After being treated by the dehydration tower in step 2), the bottom of the dehydration tower obtains rectification wastewater, which enters the biochemica...

Embodiment 3

[0042] 1) After the glyphosate hydrolysis tail gas is alkali-washed, it is treated in an alkali-washing tower to make the pH of the tail gas reach 7.0;

[0043] 2) The neutral tail gas enters the initial distillation tower for treatment. The temperature at the top of the initial distillation tower is controlled at 64°C, and the temperature at the bottom of the tower is 108°C. The liquid phase obtained at the bottom of the initial distillation tower enters the dehydration tower, and the temperature at the top of the dehydration tower is controlled at 99°C. The temperature at the bottom of the tower is 105°C, the COD of the waste water at the bottom of the dehydration tower is less than 1000mg / L, the gas phase obtained from the top of the primary distillation tower enters the methanol rectification tower for treatment, and the temperature at the top of the methanol rectification tower is controlled at 43°C, and the temperature at the bottom of the tower is 76°C;

[0044] 3) After...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com