Mesoporous materials modified with amine groups and their application in the separation of molybdenum and rhenium

A technology of mesoporous material and amine-based function, applied in the field of mesoporous material preparation and effective extraction of scattered metals, can solve the problems of unsatisfactory separation effect of molybdenum and rhenium, co-adsorption and co-analysis of molybdenum and rhenium, and difficulty in extraction and separation. , to achieve the effect of abundant raw materials, reduced processing costs and low costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033]Example 1 Amino functionalized modified mesoporous material B7SS-5-3h-5.5@0.2NH 2

[0034] First, mix 7g of mesitylene with P123 solution (dissolve 4.0g of P123 in 120mL of deionized water, and add 20mL of HCl) to obtain a mixed solution A, and the first part of 5g of Na 2 SiO 3 Dissolve in deionized water of equal mass, add to mixed solution A, and stir at 40°C to obtain mixed solution B. After reacting for 3h, the second part of 5.5g Na 2 SiO 3 Dissolve it in deionized water of equal mass, then add it dropwise to the mixed solution B, stir at 40°C for 6h, age at 100°C for 24h, filter with suction, wash the precipitate, and dry. The dried product was placed in a muffle furnace, heated to 550°C at a rate of 1-2°C / min, and roasted for 4 hours to obtain the product SBA-15, named B7SS-5-3h-5.5, with a yield of 21%.

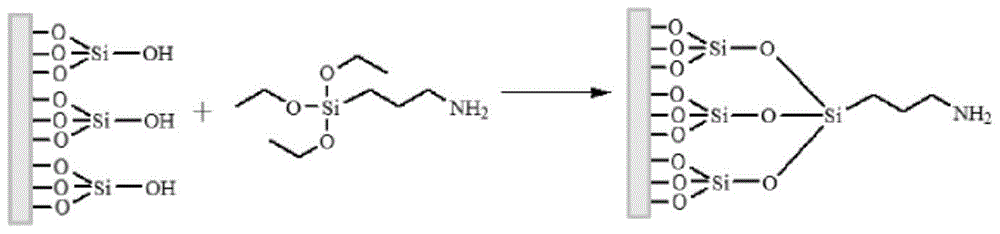

[0035] Put the prepared 2.21g (0.0368mol) of SBA-15 in a three-necked flask, add 80mL of ethanol solution, add 1.63g (0.0074mol) of APTES under nitrogen p...

Embodiment 2

[0037] Example 2 Amino functionalized modified mesoporous material SS-5-3hB7-5.5@0.2NH 2

[0038] The first part of 5g Na 2 SiO 3 Dissolve in deionized water of equal mass, then add dropwise into P123 solution (4.0g P123 dissolved in 120mL deionized water, and add 20mL HCl), stir at 40°C to obtain mixed solution C. After reacting for 3 hours, first add 7g of mesitylene into the above mixed solution C, stir to obtain mixed solution D, and then add 5.5g of the second part of Na 2 SiO 3 Dissolve it in deionized water of equal mass, then add it dropwise to the mixed solution D, stir at 40°C for 6h, age at 100°C for 24h, filter with suction, wash the precipitate, and dry. The dried product was put into a muffle furnace, heated at a rate of 1-2°C / min to 550°C and calcined for 4 hours to obtain SBA-15, named SS-5-3hB7-5.5, with a yield of 20%.

[0039] Put the prepared 2.1g (0.035mol) of SBA-15 in a three-necked flask, add 80mL of ethanol solution, add 1.55g (0.007mol) of APTES ...

Embodiment 3

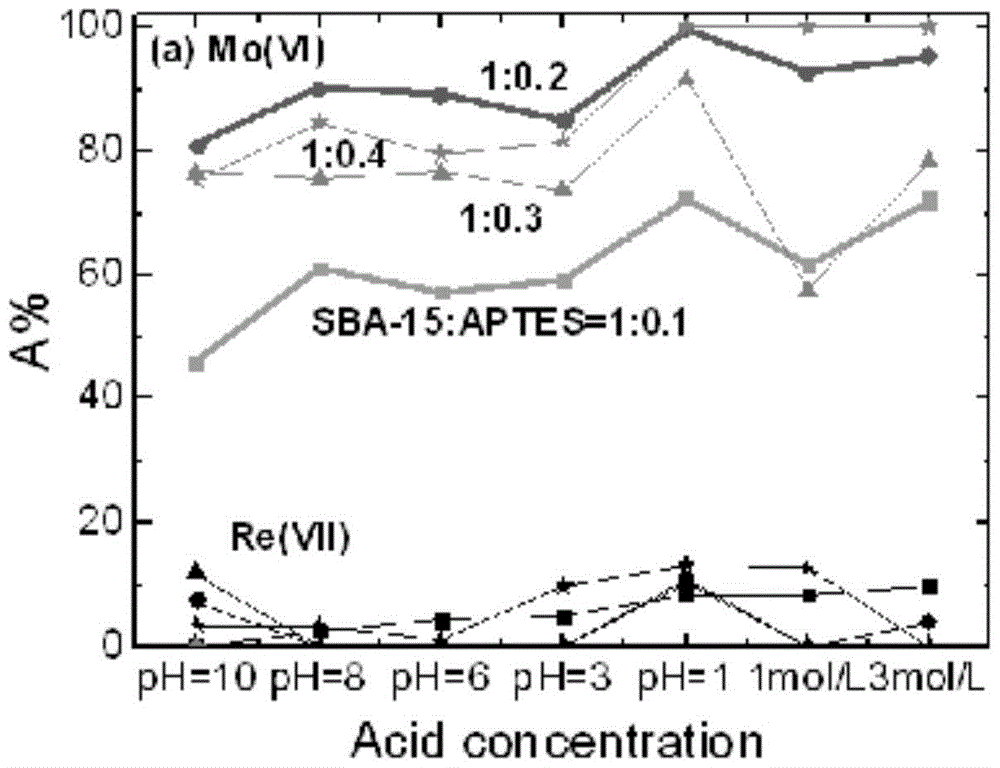

[0044] Example 3 Effect of Amino-functionalized Modified Mesoporous Materials on the Molybdenum-Rhenium Separation Effect at Different Acidity and Molar Ratio

[0045] Method: Take 5 mL of each solution containing Mo(VI) 20ppm and Re(VII) 20ppm ions, adjust the acidity of the solution to pH=10, pH=8, pH=6, pH=3, pH=1, 1mol L -1 , 3mol L -1 ; Regulate the molar ratio of SBA-15 and APTES to be 1:0.1, 1:0.2, 1:0.3, 1:0.4 respectively. Then add 10 mg of amine functionalized modified mesoporous material B7SS-5-3h-5.5@nNH 2 or SS-5-3hB7-5.5@nNH 2 , oscillating adsorption for 24 hours, the result is as follows figure 1 with figure 2 shown.

[0046] Depend on figure 1 with figure 2 It can be seen that after modification, the adsorption effect on molybdenum is better, up to 100%, and there is basically no adsorption on rhenium, so the effect of separating molybdenum and rhenium can be effectively achieved. B7SS-5-3h-5.5@0.2NH 2 and SS5-3hB7-5.5@0.2NH 2 The maximum adsorptio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com