Cementitious capillary crystalline waterproofing building material

A technology of osmotic crystallization and building waterproofing, which is applied in the field of building materials, can solve the problems of poor waterproof durability, high brittleness of waterproof materials, and poor crack resistance, and achieve high impermeability pressure, strong self-healing, and high compressive strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

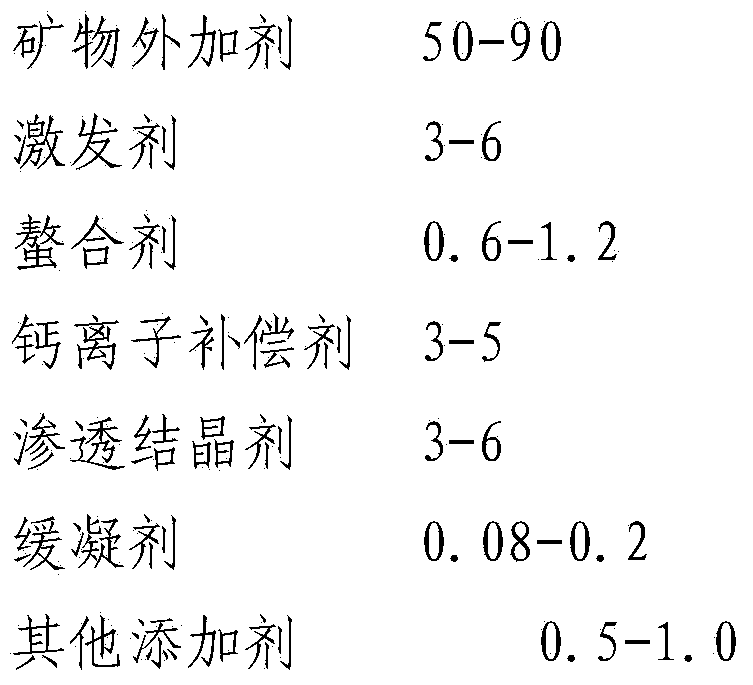

[0036] Raw material ratio (parts by weight)

[0037] Cement: 100

[0038] Quartz sand: 70, the weight ratio of coarse sand and fine sand is 2:1

[0039] Ultra-fine granulated blast furnace slag powder: 60

[0040] Aluminum Potassium Sulfate: 3.2

[0041] Tartaric acid: 0.8

[0044] Citric acid: 0.1

[0045] Other additives: 0.6, the weight ratio of defoamer and dispersant is 1:3.

Embodiment 2

[0047] Raw material ratio (parts by weight)

[0048] Cement: 100

[0049] Quartz sand: 90, the weight ratio of coarse sand and fine sand is 2.5:1

[0050] Ultra-fine granulated blast furnace slag powder: 78

[0051] Aluminum Potassium Sulfate: 4.5

[0052] Maleic acid: 0.9

[0055] Retarder: 0.15

[0056] Other additives: 0.8, the weight ratio of defoamer and dispersant is 1:2.

Embodiment 3

[0058] Raw material ratio (parts by weight)

[0059] Cement: 100

[0060] Quartz sand: 100, the weight ratio of coarse sand and fine sand is 3:1

[0061] Ultra-fine granulated blast furnace slag powder: 85

[0062] Aluminum Potassium Sulfate: 5.4

[0063] Maleic acid: 1.1

[0066] Citric acid: 0.18

[0067] Other additives: 1.0, the weight ratio of defoamer and dispersant is 1:1.

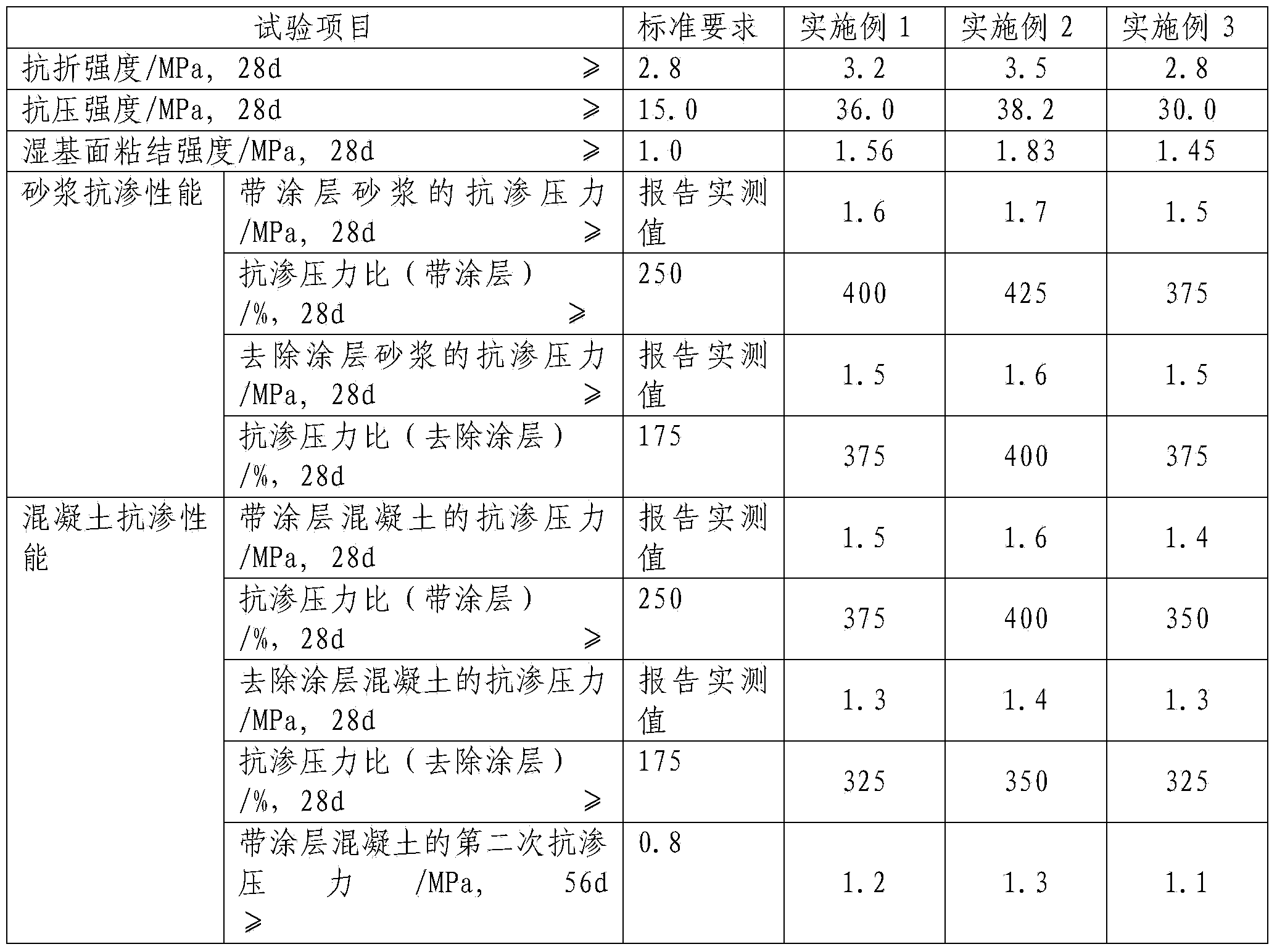

[0068] The test results of the above three embodiments are compared with the requirements of GB18445-2012, as shown in Table 1:

[0069] Table 1 Comparison table of test results

[0070]

[0071] It can be seen from the comparison table of test results that the compressive strength and impermeability pressure of the present invention are far higher than the standard requirements, and it is a very excellent waterproof material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com