Collimating lens rear surface self-calibration co-light-path interferometer based on acoustic-optical heterodyning phase shifting

A technology of collimating mirror and interferometer, applied in the field of optics, can solve the problems that the accuracy cannot meet the requirements of high-precision measurement, the development of tunable lasers is difficult, the difficulty and cost of making reference mirrors are high, and it is beneficial to solve the phase, Overcome the influence of noise and other factors, the difficulty of development and the effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

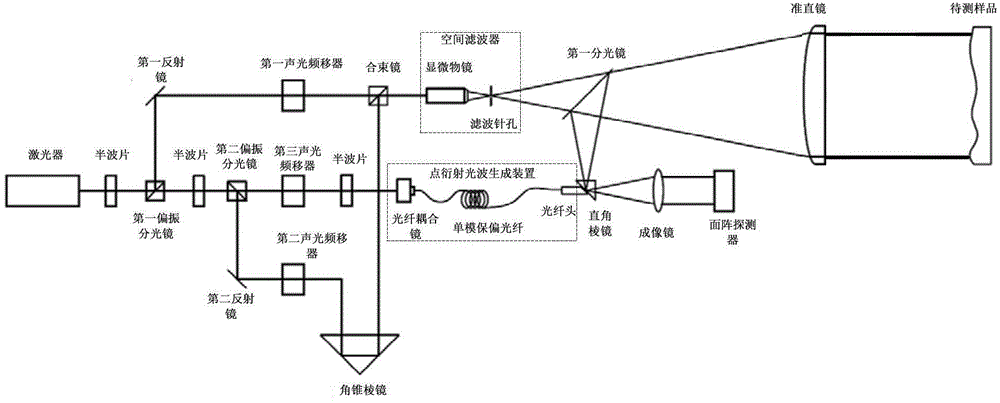

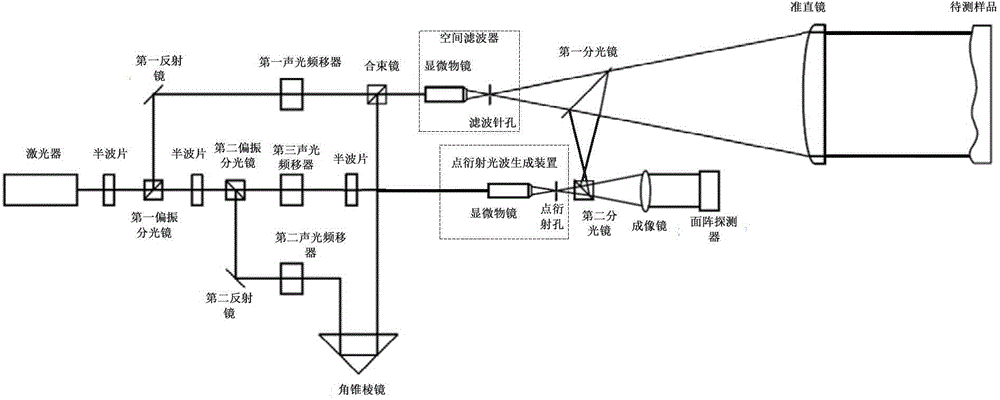

[0029] figure 1 A schematic diagram of a rear surface self-calibrating common optical path interferometer based on acousto-optic heterodyne phase shifting provided for an embodiment of the present invention. Such as figure 1 As shown, it mainly includes:

[0030]Laser, first and second polarization beam splitters, first, second and third acousto-optic frequency shifters, first and second mirrors, beam combiner, spatial filter, point diffraction light wave generation device, first beam splitter Mirror, collimating mirror, optical fiber head, rectangular prism or second beam splitter, imaging mirror and area array detector; the collimating mirror is composed of one or a group of lenses, and its last surface is designed as a plane, hereinafter referred to as is the last plane of the collimating mirror;

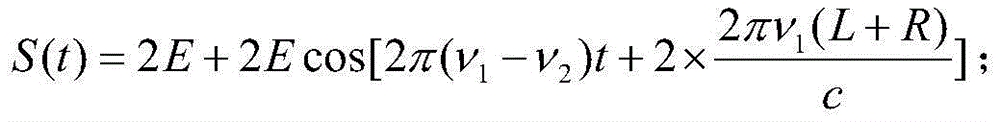

[0031] Wherein, the outgoing light of the laser is split into three beams a, b and c through the first and second polarizing beam splitters in sequence, the light a is the ref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com