A continuous temperature measuring device for aluminum electrolytic cell and its manufacturing method

A temperature measuring device, the technology of aluminum electrolytic cell, which is applied in the direction of measuring device, electric device, thermometer using electric/magnetic components directly sensitive to heat, etc. , the influence of the service life of thermocouples, etc., to achieve good thermal shock resistance, electrolyte erosion resistance, and improve current efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

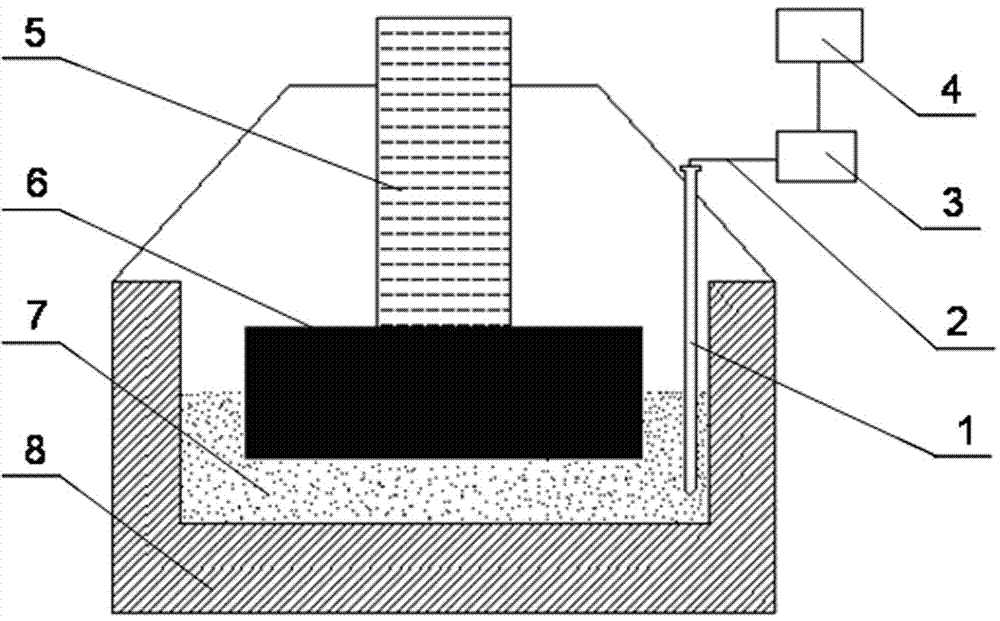

[0044] The structure of continuous temperature measuring device for aluminum electrolytic cell is as follows: figure 1 As shown, it is composed of temperature measuring thermocouple 1, compensation wire 2, single-chip microcomputer 3 and display 4; temperature measuring thermocouple 1 is connected to single-chip microcomputer 3 through compensation wire 2; single-chip microcomputer 3 is connected to display 4;

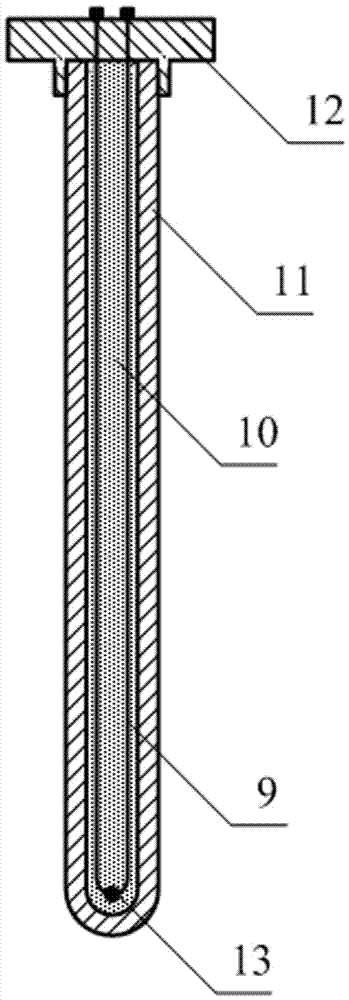

[0045] Temperature measuring thermocouple 1 is a K-type thermocouple with a structure such as figure 2 As shown, it is composed of a thermal electrode 9, an insulating material 10, a protective sleeve 11 and a junction box 12; the junction box 12 is fixed on the top of the protective sleeve 11; two thermal electrodes 9 are located in the protective sleeve 11, and the top is fixed on the junction box 12, the distance between the positive and negative welding joints 13 of the working ends of the two hot electrodes 9 and the inner wall of the bottom of the protective sle...

Embodiment 2

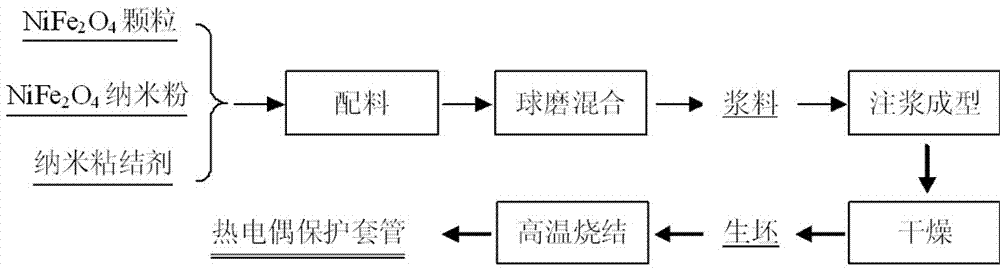

[0063] The structure of the continuous temperature measuring device of the aluminum electrolytic cell and the structure of the temperature measuring thermocouple are the same as in Example 1; the difference is that the temperature measuring thermocouple 1 is a K-type thermocouple; the distance between the positive and negative electrode welding joints and the bottom inner wall of the protective sleeve is 7mm; The wall thickness of the protective sleeve is 15mm; the composition of the protective sleeve is NiFe 2 o 4 Particles, NiFe 2 o 4 Nano powder and nano binder, respectively 85%, 10% and 5% by mass; NiFe 2 o 4 Particle size 74μm; NiFe 2 o 4 The particle size of nano powder is 65nm; the insulating material is magnesium oxide powder;

[0064] The manufacturing method of the aluminum electrolytic cell continuous temperature measuring device is the same as in Example 1, the difference is that: in step (1), the solid-liquid ratio of the mixed material to deionized water is...

Embodiment 3

[0069] The structure of the continuous temperature measuring device of the aluminum electrolytic cell and the structure of the temperature measuring thermocouple are the same as in Example 1; the difference is that the temperature measuring thermocouple 1 is an S-type thermocouple; the distance between the positive and negative electrode welding joints and the inner wall of the bottom of the protective sleeve is 4 mm; The wall thickness of the protective sleeve is 30mm; the composition of the protective sleeve is NiFe 2 o 4 Particles, NiFe 2 o 4 Nano powder and nano binder, respectively 94%, 5% and 1% by mass; NiFe 2 o 4 Particle size 38μm; NiFe 2 o 4 The particle size of nano powder is 40nm; the insulating material is magnesium oxide powder;

[0070] The manufacturing method of the aluminum electrolytic cell continuous temperature measuring device is the same as in Example 1, the difference is that: in step (1), the solid-to-liquid ratio of the mixed material to deioniz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com