Method for preparing manganese dioxide/graphene/porous carbon (MnO2/rGO/C) composite material and application of MnO2/rGO/C composite material to supercapacitor as electrode material

A supercapacitor, manganese dioxide technology, applied in hybrid capacitor electrodes, hybrid/electric double-layer capacitor manufacturing, double-layer capacitors, etc., can solve the problem of low specific capacitance and easy agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

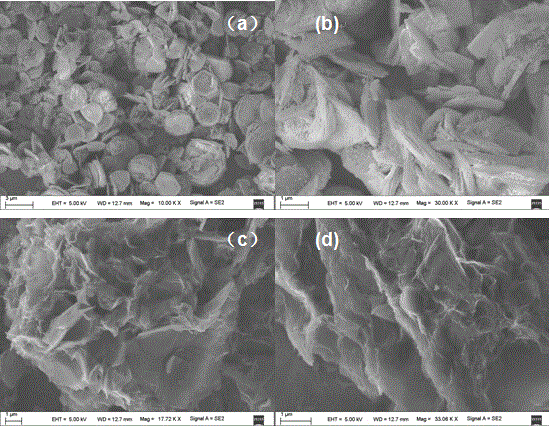

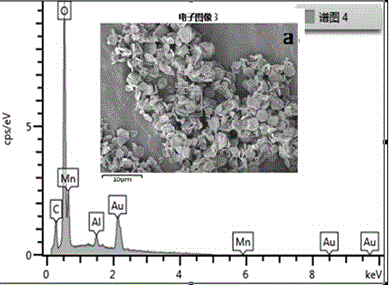

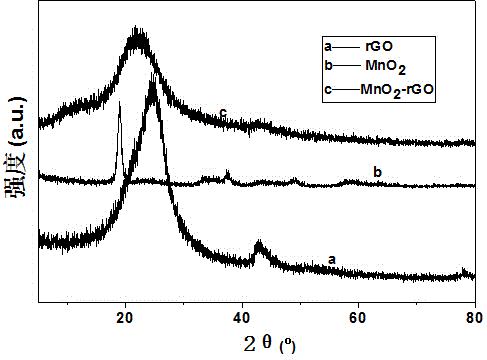

[0055] (1) Flake hexagonal manganese dioxide / graphene / porous carbon (MnO 2 / rGO / C) composites

[0056] Preparation of graphite oxide dispersion: Weigh 100 mg of graphite oxide and ultrasonically disperse it in 100 ml of distilled water to form a graphite oxide dispersion;

[0057] Preparation of flaky hexagonal manganese dioxide: Dissolve 1.264g of potassium manganate in 100ml of distilled water to form potassium permanganate aqueous solution; then disperse 1g of potato starch in 100ml of potassium permanganate aqueous solution, and stir magnetically for 5h. A mixed solution is obtained. Then use KOH solution to adjust the pH value of the mixed solution to 9~10, move it to a high-pressure reactor, and heat it in water at 180°C for 24 hours; after cooling to room temperature, filter it with suction, and wash it repeatedly with absolute ethanol and distilled water until neutral. Vacuum drying at 60°C for 12 hours to obtain flaky hexagonal manganese dioxide;

[0058] Flake hex...

Embodiment 2

[0064] (1) Flake hexagonal manganese dioxide / graphene / porous carbon (MnO 2 / rGO / C) composites

[0065] Preparation of graphite oxide dispersion: Weigh 100g of graphite oxide and ultrasonically disperse it in 80ml of distilled water to form a graphite oxide dispersion;

[0066] Preparation of flaky hexagonal manganese dioxide: Dissolve 1.3g of potassium manganate in 100ml of distilled water to form potassium permanganate aqueous solution; then disperse 0.8g of potato starch in 100ml of potassium permanganate aqueous solution, and magnetically stir for 5 hours , to obtain a mixed solution. Then use KOH solution to adjust the pH value of the mixed solution to 9~10, move it to a high-pressure reactor, and heat it in water at 180°C for 24 hours; after cooling to room temperature, filter it with suction, and wash it repeatedly with absolute ethanol and distilled water until neutral. Vacuum drying at 60°C for 12 hours to obtain flaky hexagonal manganese dioxide;

[0067] Flake hex...

Embodiment 3

[0073] (1) Flake hexagonal manganese dioxide / graphene / porous carbon (MnO 2 / rGO / C) composites

[0074] Preparation of graphite oxide dispersion: Weigh 100g of graphite oxide and ultrasonically disperse it in 120ml of distilled water to form a graphite oxide dispersion;

[0075] Preparation of flaky hexagonal manganese dioxide: Dissolve 1.1g of potassium manganate in 100ml of distilled water to form potassium permanganate aqueous solution; then disperse 0.7g of potato starch in 100ml of potassium permanganate aqueous solution and stir magnetically for 5 hours , to obtain a mixed solution. Then use KOH solution to adjust the pH value of the mixed solution to 9~10, move it to a high-pressure reactor, and heat it in water at 180°C for 24 hours; after cooling to room temperature, filter it with suction, and wash it repeatedly with absolute ethanol and distilled water until neutral. Vacuum drying at 60°C for 12 hours to obtain flaky hexagonal manganese dioxide;

[0076] Flake hex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| volume ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com