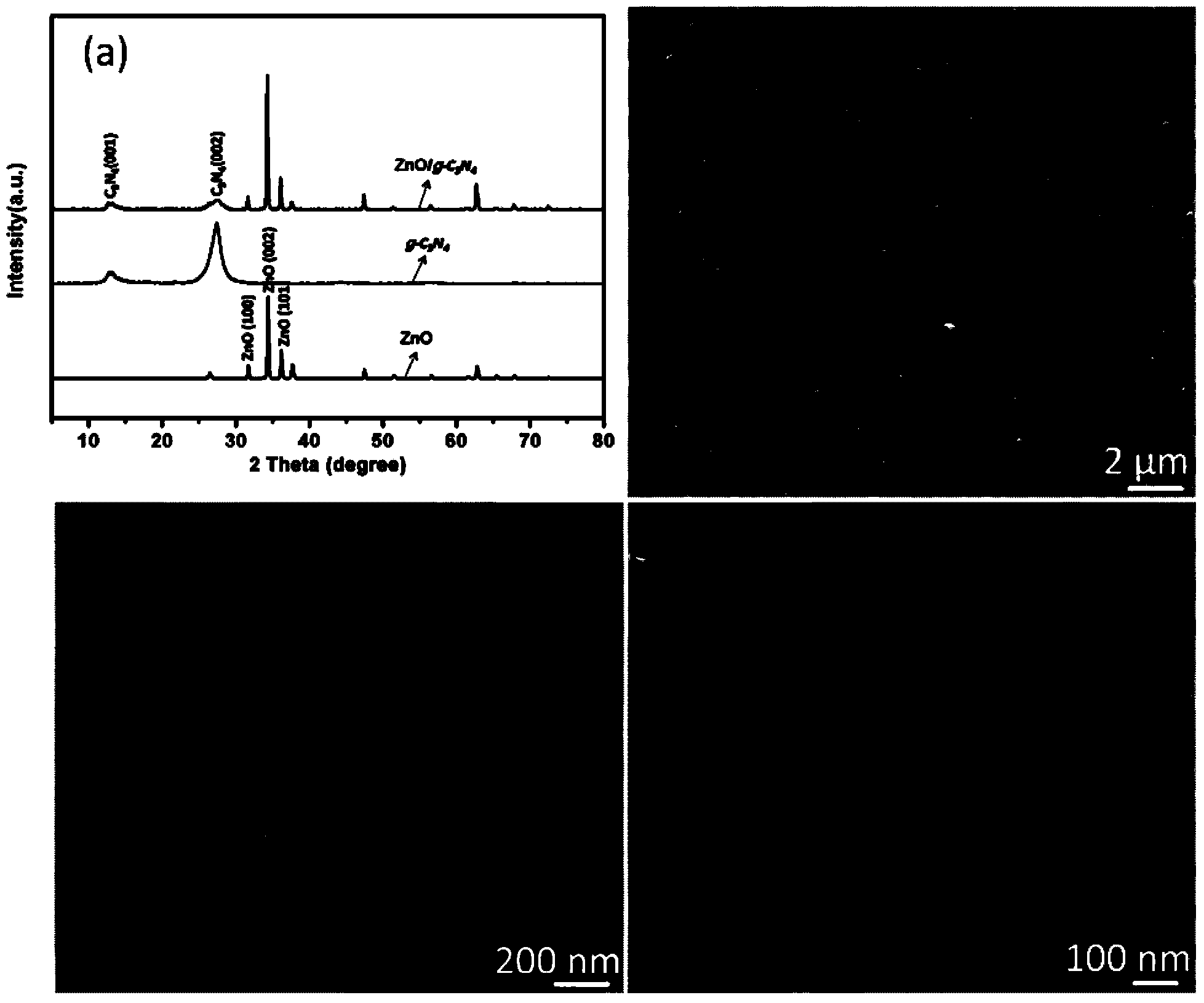

ZnO/g-C3N4 nanocomposite and preparation method thereof

A nanocomposite material and composite material technology are applied in the field of ZnO/g-C3N4 nanocomposite materials and their preparation, and achieve the effects of simple conditions, wide band gap, and improvement of light-responsive current density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

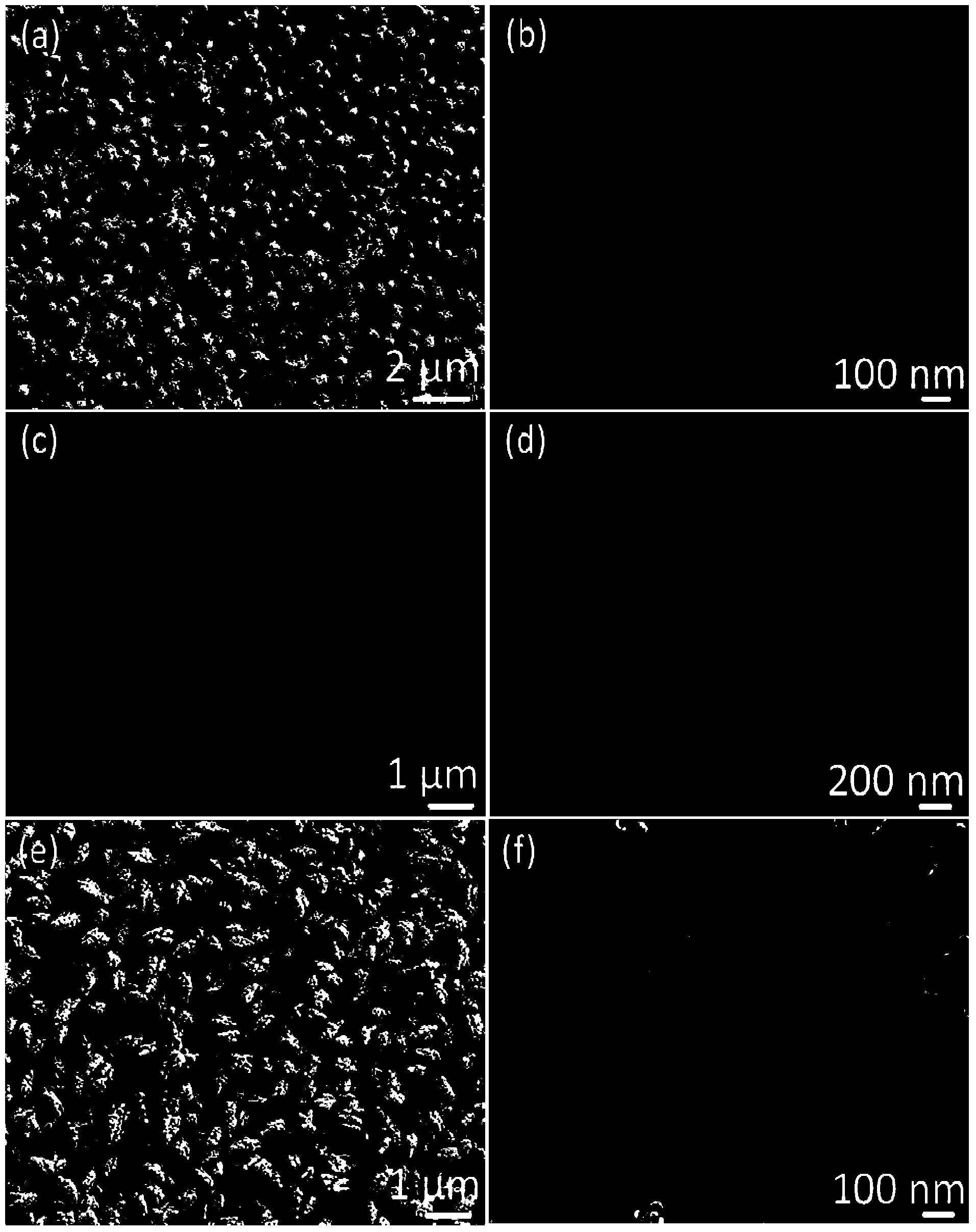

[0032] The synthesis of ZnO nanorods on FTO conductive glass is achieved by electrochemical deposition. Before the electrochemical deposition reaction, FTO conductive glass (2.5cm x 1.5cm) was ultrasonically cleaned in absolute ethanol and acetone, deionized water, absolute ethanol and acetone for 10 minutes, and then soaked in absolute ethanol and acetone. spare. The FTO conductive glass obtained above is placed in a standard three-port electrolytic cell containing a ZnO nanorod growth solution (the reaction solution is generally 20 mL), and the electrochemical deposition reaction is maintained at 90° C. for 50 min. The composition of the electrochemical deposition reaction solution of ZnO nanorods is 0.02mol / L Zn(NO 3 ) 2 ·6H 2 O solution, 0.01mol / L CH 3 COONH 4 Solution, 0.01mol / L HMT solution. After the reaction, the carrier on which the ZnO nanorods were grown was taken out and washed three times with deionized water, and dried at room temperature.

[0033] Place the FTO c...

Embodiment 2

[0036] The invention is based on the scheme of Example 1, which influences ZnO / g-C by adjusting different reaction conditions 3 N 4 The relationship is shown in Table 1.

[0037] Table 1.g-C 3 N 4 Growth regulation

[0038]

[0039]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com