Silver triangular nano-particle array/single-layer graphene thin film composite

A nanoparticle array, thin film composite material technology, applied in graphene, nanocarbon, nanotechnology and other directions, can solve problems affecting device performance, unavoidable pollution and damage, achieve good optoelectronic performance, ensure integrity, and ensure cleanliness sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

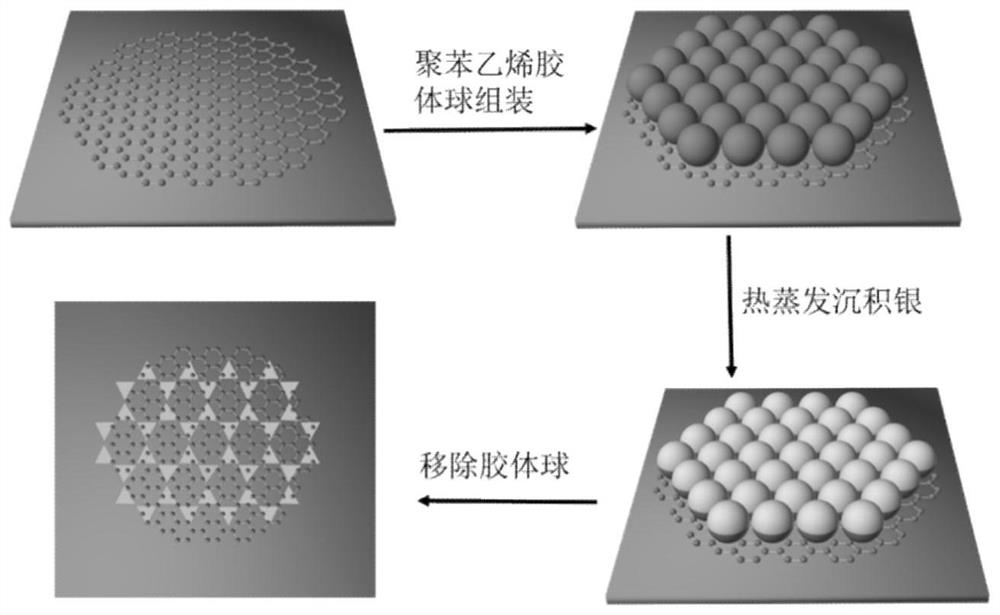

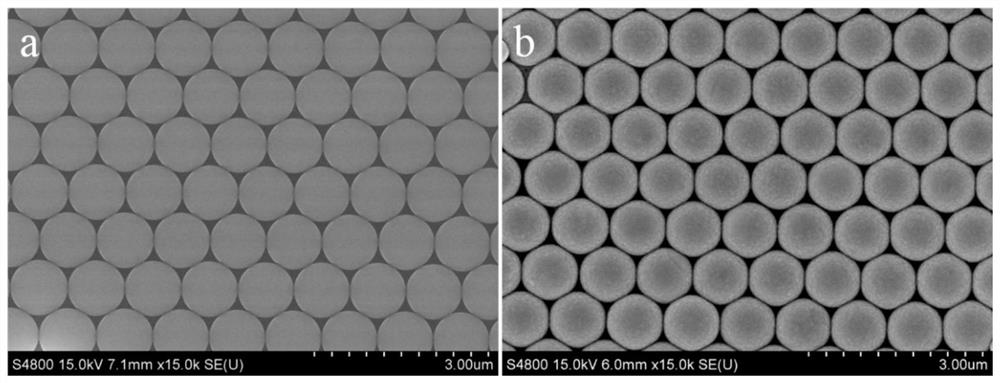

[0030] (1) CVD growth of single-layer graphene film. Put a copper foil (Alfa Aesar, 99.8%) with a thickness of 25 μm into a tube furnace, and anneal at 1000 °C for 30 min in a mixed atmosphere of hydrogen (100 sccm) and argon (300 sccm) to remove oxides on the surface of the copper foil; Add methane (10 sccm) again, turn off the hydrogen and methane after growing for 30 min, and cool to room temperature under the protection of argon, and a single-layer graphene film can be grown on the copper foil. (2) Synthesis of PS ball template / single layer graphene film / copper foil. PS sphere suspension (2.5 wt%) with a diameter of 1 μm and ethanol were ultrasonically mixed at a volume ratio of 1:1. Add an appropriate amount of deionized water to a clean glass slide to form a large-area thin water film, take about 0.1 mL of the PS sphere mixture to the surface of the water film, and the PS spheres spontaneously self-assemble at the gas-liquid-solid interface to form a large-area single-l...

Embodiment 2

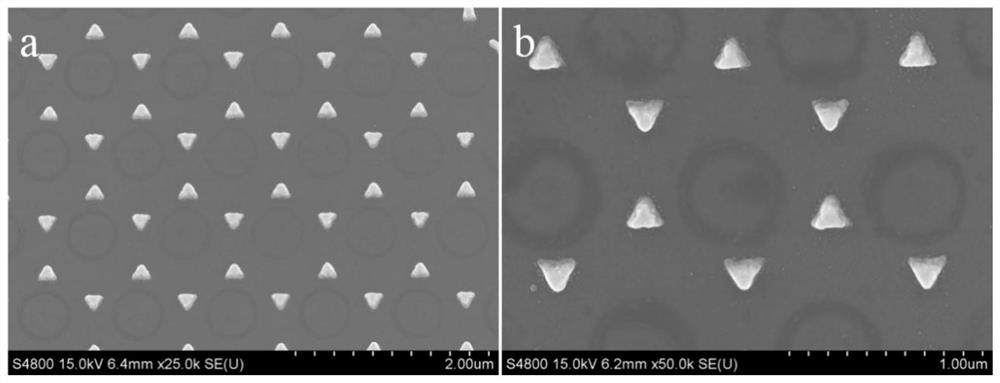

[0036] Other steps and processing conditions are identical with embodiment 1. The difference is that before step (3), the two single-layer PS ball templates obtained in step (2) were heat-treated at 110°C / 10min and 110°C / 20min respectively to obtain Silver triangular nanoparticle array / single-layer graphene film / copper foil morphology ( Figure 5 a) Silver triangular nanoparticle array / single-layer graphene film / copper foil morphology under heating conditions of 110°C / 20min ( Figure 5 b).

[0037] Compared Figure 5 a and Figure 5 b, combined simultaneously image 3, we can find that the heat treatment of the PS sphere template has a significant effect on the triangular size, and as the heating time of the PS sphere template before the deposition of silver increases, the size of the final silver triangular nanoparticles also decreases. Therefore, the size of the silver triangular nanoparticles can be tuned by changing the heating conditions of the PS sphere template bef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com