CZTS film surface secondary phase etching method

A copper-zinc-tin-sulfur, secondary phase technology, applied in photovoltaic power generation, sustainable manufacturing/processing, electrical components, etc., can solve problems such as deliquescence, neurasthenia syndrome, eye and upper respiratory tract irritation, and human injury. Achieve good photoelectric performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] In the present embodiment, the method for etching the secondary phase on the surface of the copper-zinc-tin-sulfur film comprises the following steps:

[0030] a. Mix concentrated hydrochloric acid with a mass fraction of 37.5% and deionized water at a volume ratio of 1% to prepare a hydrochloric acid solution.

[0031] b. Place the sulfided copper-zinc-tin-sulfur thin film to be etched in the hydrochloric acid solution prepared in step a, and ensure that the hydrochloric acid solution is excessive.

[0032] c. Put the solution in step b in a constant temperature water bath, and set the temperature of the water bath to 75°C.

[0033] d. Hydrochloric acid reacts with the ZnS secondary impurity phase on the surface of the copper-zinc-tin-sulfur film, and the reaction equation is:

[0034]

[0035] ZnCl produced by the reaction 2 Soluble in water, thus successfully removing the ZnS secondary impurity phase on the surface of the CZTS film.

[0036] e. After reacting h...

Embodiment 2

[0039] Compared with Example 1, in the present embodiment, in step a, the concentrated hydrochloric acid and deionized water with a mass fraction of 37.5% are mixed in a ratio of 3% by volume to make a hydrochloric acid solution; other steps in this embodiment are all Same as Example 1.

Embodiment 3

[0041] Compared with Example 1, in this example, in step a, concentrated hydrochloric acid with a mass fraction of 37.5% and deionized water are mixed at a ratio of 0% by volume to make a hydrochloric acid solution, that is, hydrochloric acid in this example The solution is a hydrochloric acid solution with a mass fraction of 0%, that is, the hydrochloric acid solution is all deionized water; other steps in this embodiment are the same as in Example 1. To be precise, this embodiment is actually an example of not using hydrochloric acid to etch the CuZnSnS thin film.

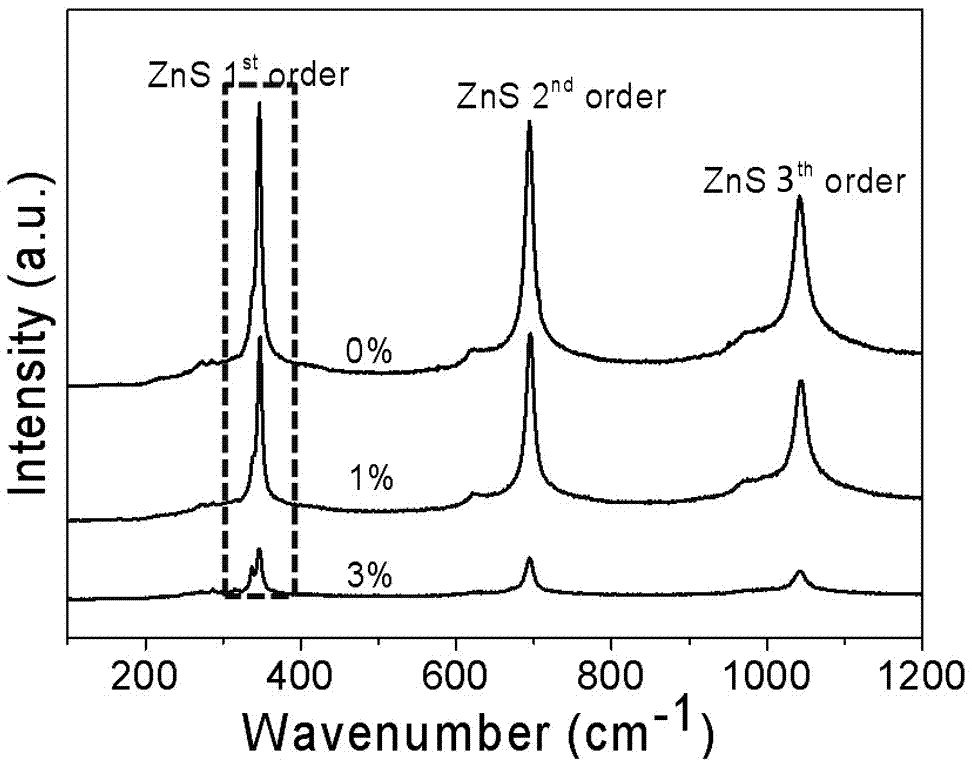

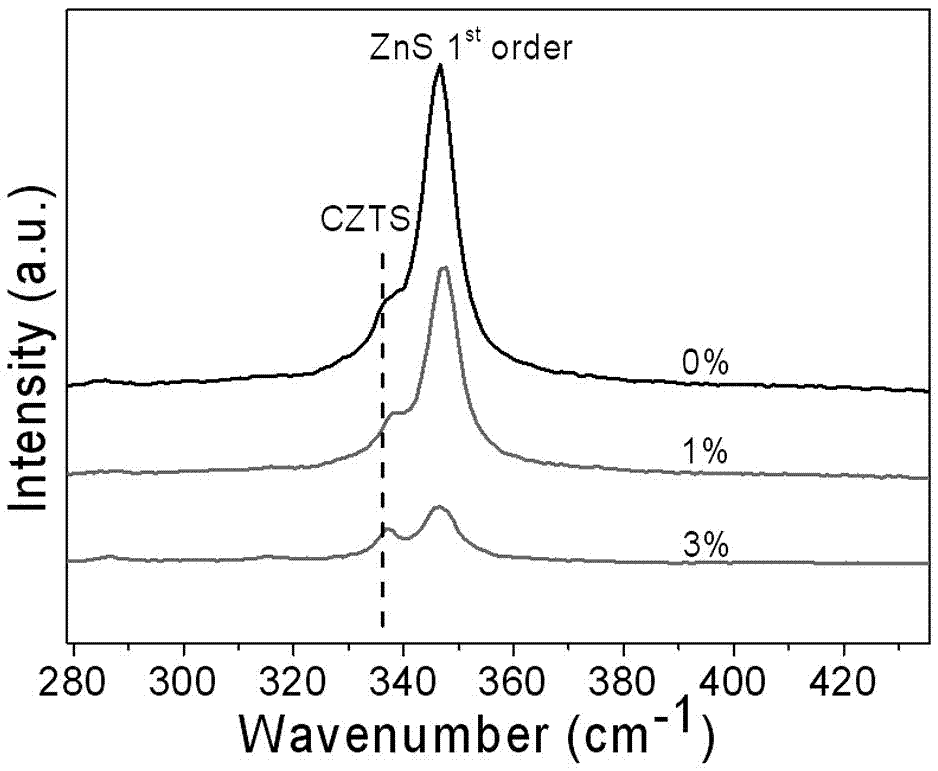

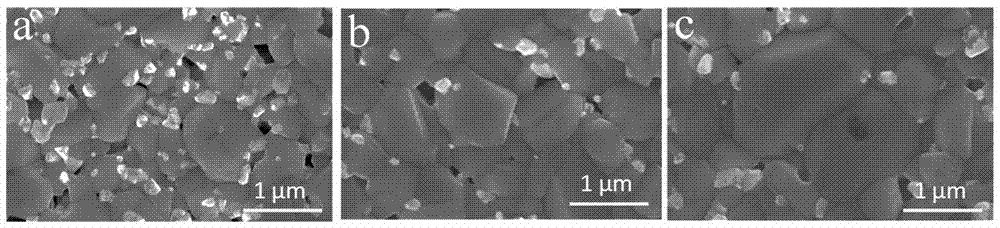

[0042] Carry out Raman scattering test to the CZTS thin film after being etched among the embodiment 1 ~ embodiment 3, adopt the laser device of 325nm during the test, the obtained result is shown in figure 1 and figure 2 , figure 2 yes figure 1 Enlarged view indicated by dashed box. Depend on figure 1 and figure 2 It can be seen that with the increase of hydrochloric acid concentration, the peak intensi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com