Flux composition, liquid flux, resin flux cored solder, and solder paste

A technology of flux and composition, applied in welding/cutting medium/material, welding medium, welding equipment, etc., can solve the problems of insufficient oxide film removal, weak activation ability of flux, poor welding performance, etc., to improve welding performance. properties, corrosion inhibition, and reaction inhibition effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

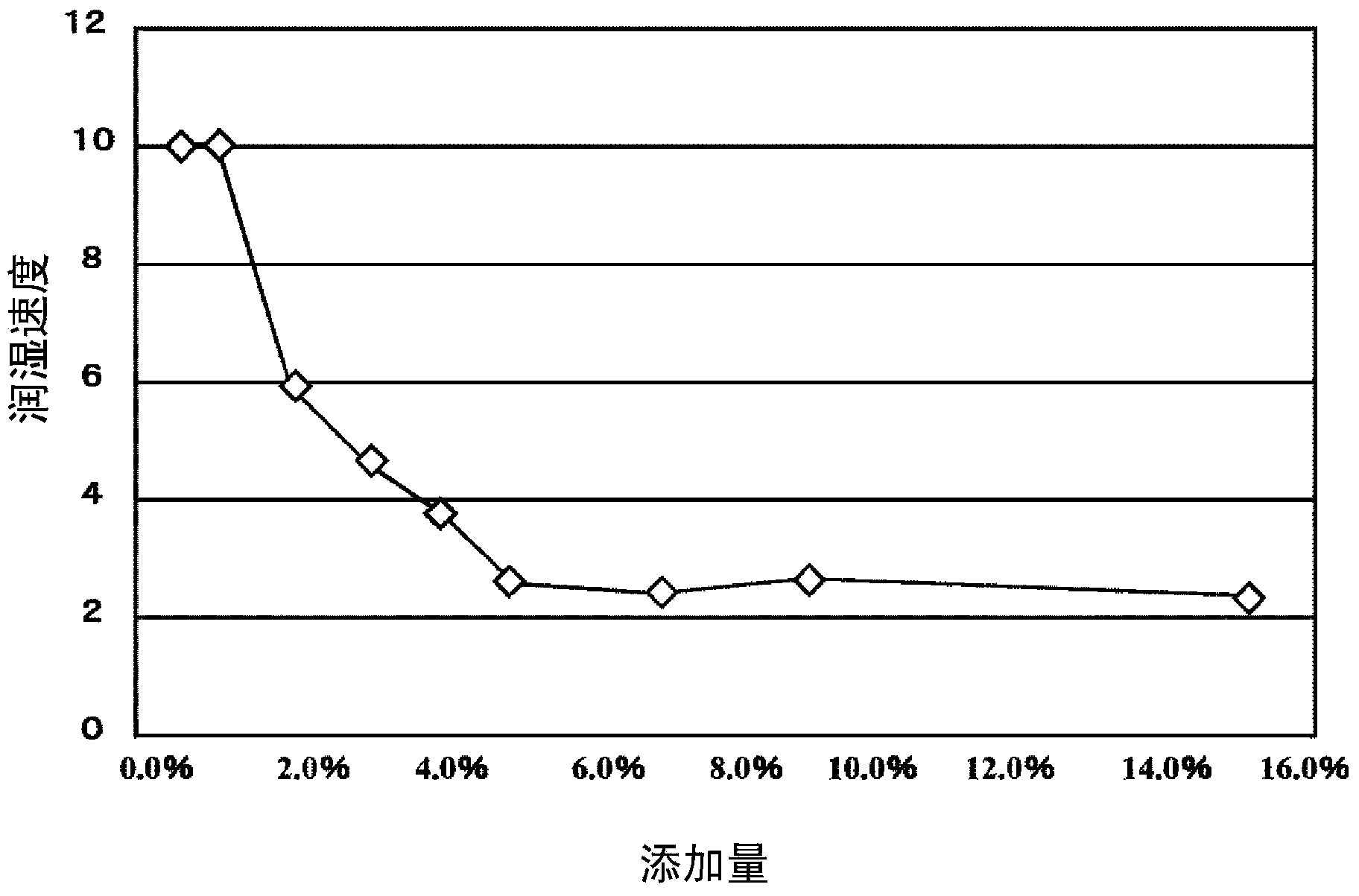

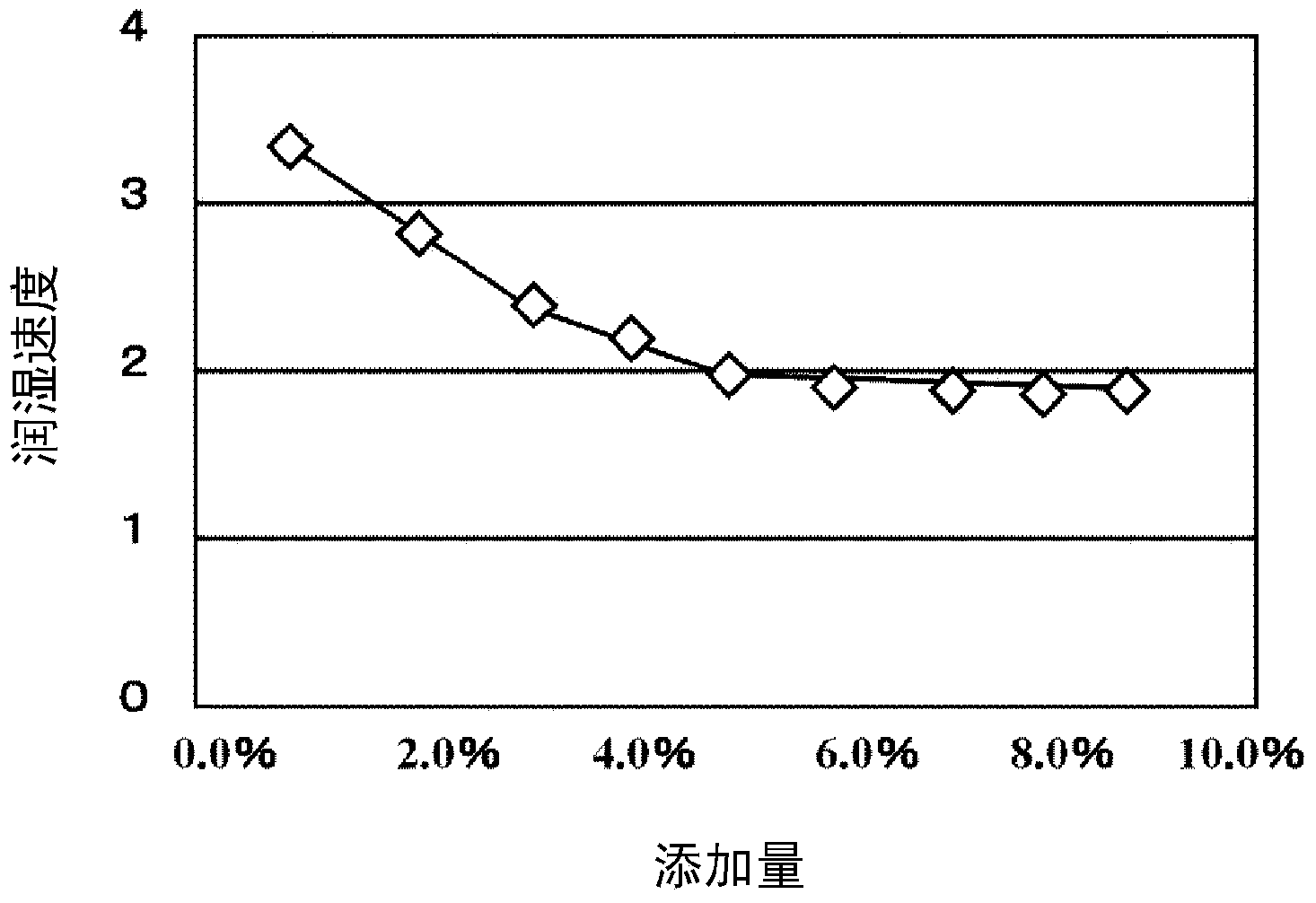

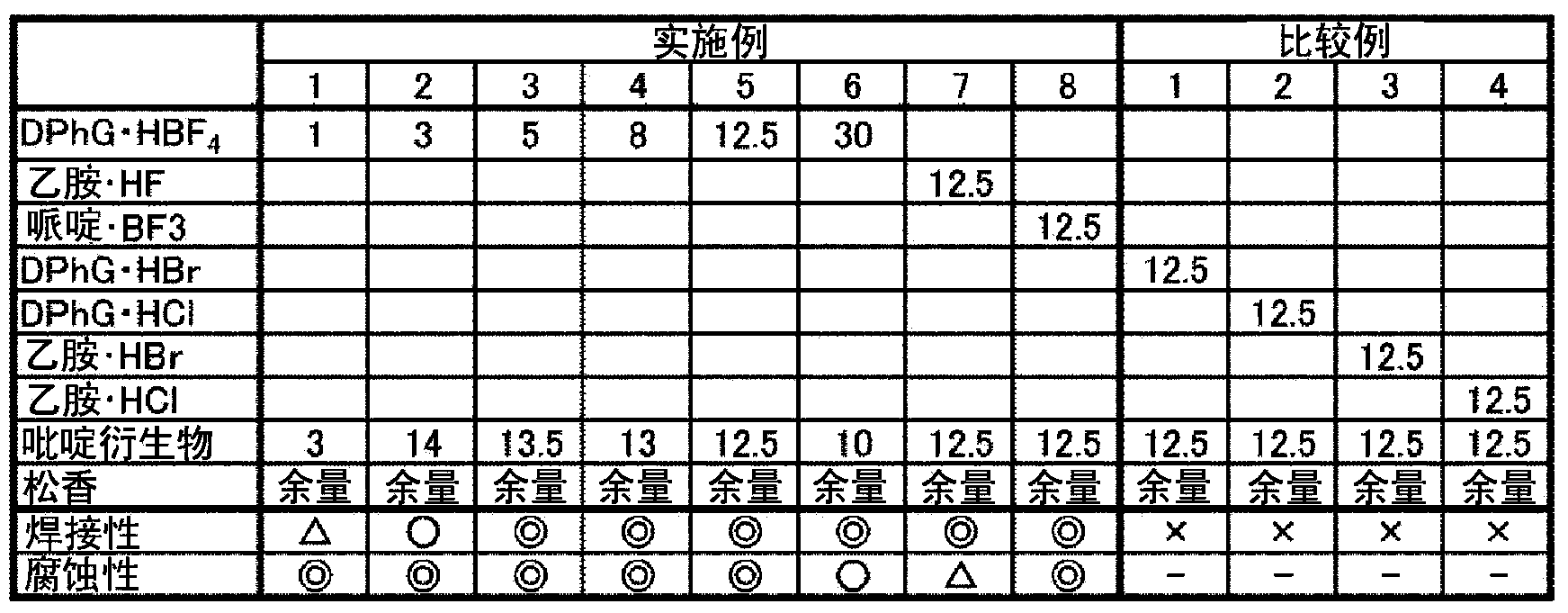

[0046] The fluxes of Examples and Comparative Examples were prepared according to the compositions shown in the following tables, and solderability, corrosion, and wettability were examined. In Examples and Comparative Examples, liquid flux obtained by dissolving a flux composition with a solvent was used. In addition, the combination rate of each example is the mass % in a flux composition. First, evaluation methods and conditions for each test will be described.

[0047] (1) Inspection of weldability

[0048] (a) Evaluation method

[0049] Place a solder ring on an aluminum plate, apply flux, heat and dissolve the solder, and check wettability.

[0050] (b) Evaluation conditions

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com