Fruit-vegetable enzyme polyphenol chewable tablets and production method thereof

A fruit and vegetable enzyme, extraction method technology, applied in food preparation, food ingredients as taste improver, food science and other directions, can solve problems such as unsatisfactory taste, quality and dosage form, and achieve improved stability, improved taste, and convenient portability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

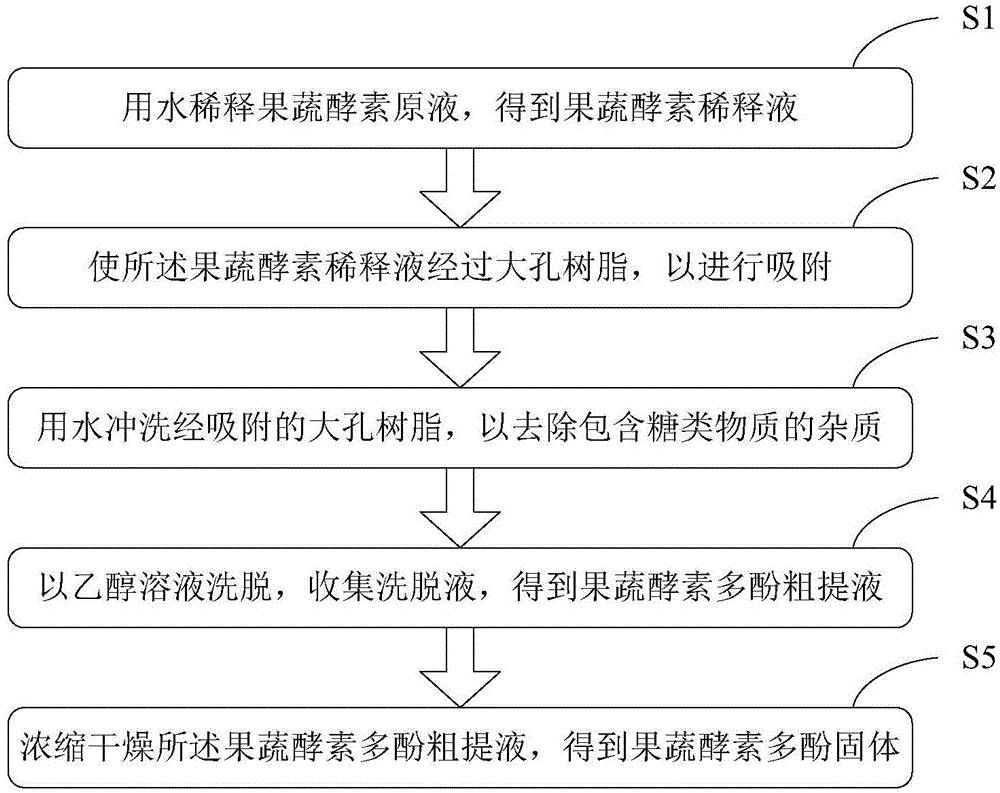

[0040] 1. Preparation of solid fruit and vegetable enzyme polyphenols:

[0041] Take an appropriate amount of fruit and vegetable enzyme stock solution, add an equal volume of pure water to dilute; make the diluted fruit and vegetable enzyme solution go through 5-10 times the volume of D101 macroporous resin for 12 hours; wash and remove impurities with 3 times the volume of pure water; use 6 times the volume of 40 % ethanol for elution, the ethanol eluent collected is the fruit and vegetable enzyme polyphenol crude extract; the crude extract is vacuum concentrated at 40°C to one-half of the original volume, and then dried by conventional vacuum spraying (inlet air temperature 120-160°C) °C, the air outlet temperature is 60-80 °C, the vacuum degree is -900 to -1000Pa, and the injection speed is 2ml / min), and the solid coarse powder of fruit and vegetable enzyme polyphenols is obtained.

[0042] The coarse powder was dissolved in 40% ethanol to prepare the test solution. The po...

Embodiment 2

[0047] 1. Preparation of crude polyphenol extracts from fruits and vegetables:

[0048] Take an appropriate amount of fruit and vegetable enzyme stock solution, add an equal volume of pure water to dilute; make the diluted fruit and vegetable enzyme solution go through 5-10 times the volume of D101 macroporous resin for 12 hours; wash and remove impurities with 3 times the volume of pure water; use 6 times the volume of 40 % ethanol for elution, the ethanol eluent collected is the fruit and vegetable enzyme polyphenol crude extract; the crude extract is vacuum concentrated at 40°C to one-half of the original volume, and then dried by conventional vacuum spraying (inlet air temperature 120-160°C) °C, the air outlet temperature is 60-80 °C, the vacuum degree is -900 to -1000Pa, and the injection speed is 2ml / min), and the solid coarse powder of fruit and vegetable enzyme polyphenols is obtained.

[0049] The coarse powder was dissolved in 40% ethanol to prepare the test solution...

Embodiment 3

[0054] 1. Preparation of crude polyphenol extracts from fruits and vegetables:

[0055] Take an appropriate amount of fruit and vegetable enzyme stock solution, add an equal volume of pure water to dilute; make the diluted fruit and vegetable enzyme solution go through 5 times the volume of D101 macroporous resin for 12 hours; wash with 3 times the volume of pure water to remove impurities; use 6 times the volume of 40% ethanol Elution, collecting the ethanol eluent is the crude extract of fruit and vegetable enzyme polyphenols; the crude extract is concentrated to half of the original volume by low-temperature vacuum at 40°C, and then dried by conventional vacuum spraying (inlet air temperature 120-160°C, The air outlet temperature is 60-80°C, the vacuum degree is -900 to -1000Pa, and the injection speed is 2ml / min), and the solid coarse powder of fruit and vegetable enzyme polyphenols is obtained.

[0056] 2. Preparation of polyphenol chewable tablets:

[0057] Components (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sheet weight | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com